Hi to everybody. I will jumb right to my problem. I have really bad cutting edges on my CO2, it’s AL960 it’s chiness machine with leadshine 3 phase Nema23. The microstepping is at low settings (400). When we bought the machine the PSU didn’t work from day one it was bad and we change it with Meanwell 36V 9,7A. I think that for this type of machine is great choice. At first it didn’t bother me with harsh edges, but right now I think that I have harmonic stutter, on top side I would say that cutting is litlle better than on the lower side.

This image is from the internet, but I will upload my images, the finish result is not this harsh, but you can see it and feel under fingernail.

https://forum.lightburnsoftware.com/uploads/default/original/3X/4/e/4e5ad5b4e0a83816612b2cacffdd2097d3e6973a.jpeg

If I cut acrylic 3-5mm with very low speed 10-15mm with 35-40% (The tube is RECI 90W agreement power, the max is around 103W) than I am losing my dimnesion because I am “burning” polishing edges and don’t have striation on the side, but I know that machine can cut with much greater speed, and for some random projects I am cutting with 50-60mm with 85% of power for 3mm acrylic.

From manual I see that Steppers need 5,8A and resistance is around 0,86, So if all

3 phase is active that will be 87W (never is but just to be sure in , but my dip switches are set to Peak (5,3A) and RMS (3,8A). Do I need to lok for Peak or RMS scale.

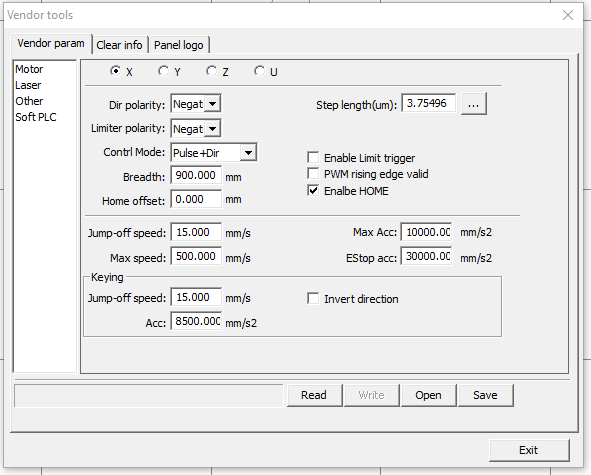

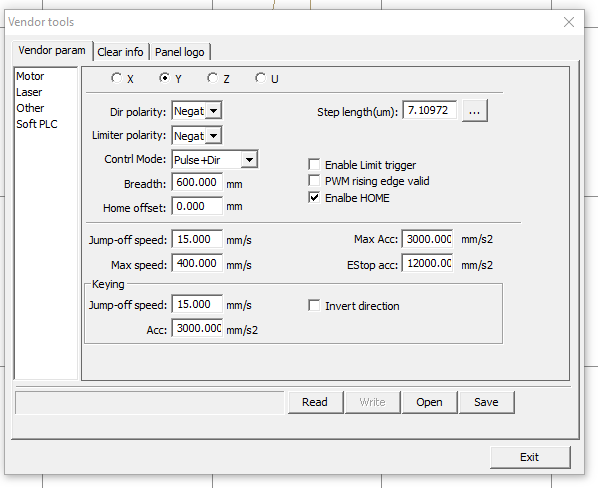

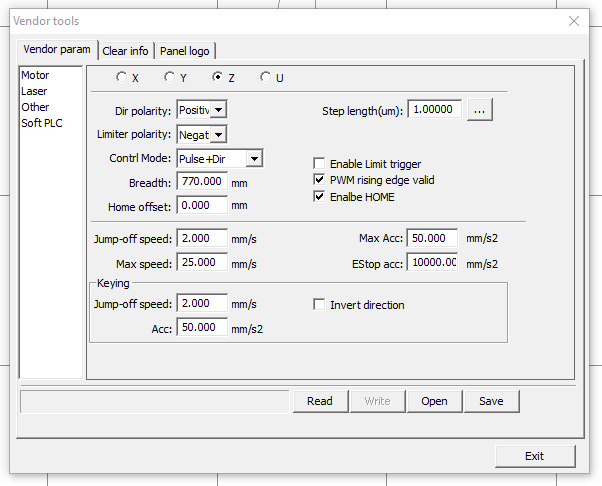

Some other information:

Controller Ruida RDC6445S

Stepper motor is Nema 23 - 3 Phase - [Model 573S15-L] - (For X -1 pcs and Y - 1 pcs)

Stepper Driver is [Leadshine 3DM580S]

Stepper driver for Z axis is [2DM542-06]

Images are in album on google photos