I’ve already done that several times, unfortunately no change

meanwhile i somehow managed that i can no longer control my rotary via lightburn ![]()

![]()

Can you restore the controllers settings via your backup. By the sound of things that’s about the only option left to get you moving…

![]()

unfortunately not

I have no backup

Might search your drive for a .lbset …

I just looked and found this ‘backup’ from February… Might want to look for something similar and see if you can restore it…

Backup what you have first…

-rw-rw-r-- 1 jack jack 12964 Feb 23 08:27 /home/jack/.config/LightBurn/backup/machine_settings/jhhZGM4LWY/20220223_082702.lbset

Good luck

![]()

how do I do that

It’s the controls at the bottom of the gui… It’s pretty clear, but I’ll let you check out the document.

Keep in mind that you need to write changes back to the controller…

![]()

ok i made a backup first

meanwhile i managed to drive my laser again like i wrote at the beginning

So… is it fixed? what did you do to fix it?

![]()

actually it hasn’t been fixed yet because I had reduced the steps so that I couldn’t see that it was moving

during testing and also when I make a frame or the laser itself

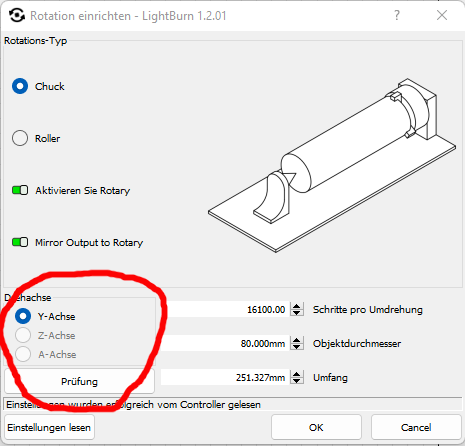

still moves the Y instead of the rotary

I can still only move the rotary manually

as I described it here at the beginning

I’ve had problems with it since the beginning

We know these work, so it has to be a configuration issue…

I’d suggest you drop a line to support@lightburn with the issue. Indicate your controller and how you have it setup for the U axes. I would think you should see an option for that axes and you don’t, indicating to me that Lightburn doesn’t think it’s an option.

@micrololin is partially correct, or correct, depending on what he means.

When you set up a rotary, the machine needs to know how many steps to rotate the drive wheel or chuck for a complete turn. Knowing the steps/rotation of the motor is required for both types. At this point it doesn’t matter if it’s a wheel or chuck.

With a chuck you are done, but need to enter the diameter for different objects.

A ‘wheel’ type, the ‘driving’ wheel diameter only once.

You need to have it set up as a chuck type or you’ll be figuring steps/rotation when you change to a different diameter object.

Take the steps/rotation of your rotary, multiply it by the ‘ratio’ and use that for steps/rotation of a chuck type rotary. That should fix any anomalies with how far it rotates.

Good luck…

![]()

With my chuck rotary it’s a direct drive. This rotary has a belt with a small pulley on stepper and a large on the chuck.

In the end, steps/rotation should account for the gear ratio of the driving motor. All the software needs to know is a complete rotation, how it’s done at the mechanical end is pretty much irrelevant.

The disadvantage of setting up as a wheeled rotary, you would have to compute surface speed on any object that was a different diameter, whereas Lightburn does that for you with a chuck type.

If mine was a chuck, it’s 2000 steps/rotation for the motor and a 2.5 ratio, so I’d set the chuck up as a ‘chuck’ with the steps/rotation at 2000 * 2.5 or 5000 steps/rotation. It doesn’t know… and it should act properly.

![]()

I think maybe I should do that

thanks

Please report back when it’s fixed. It’s nice when you have a problem and find a thread with an understandable fix…

Take care and good luck

![]()

I informed the support about this conversation because otherwise I would have to write everything again

Perfect, thought about advising that, but spaced it by the end of the text I was typing… ![]()

Good luck

![]()

I first changed the firmware to v15.01.30 with the help of support