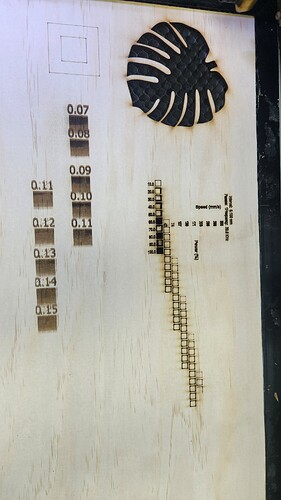

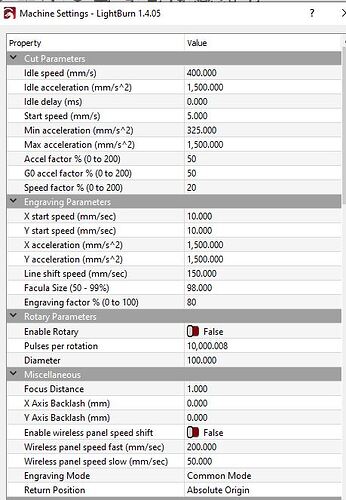

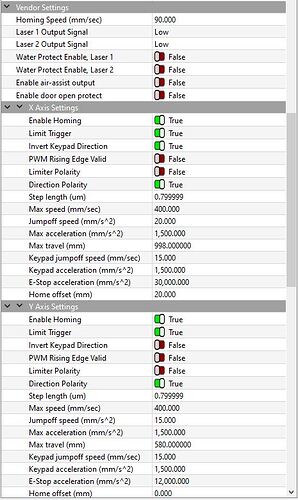

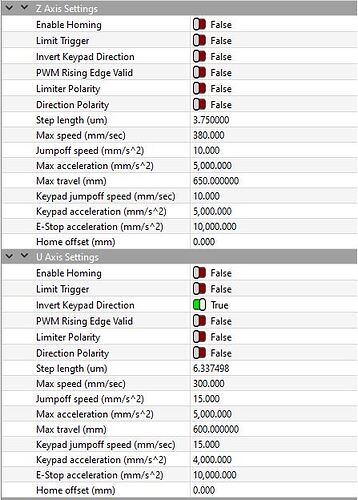

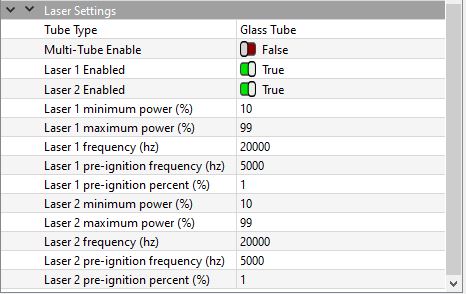

I have a blue and white Chinese 1060 laser, which for all intents and purposes had k40 hardware up until a few days ago. It’s now sporting a Ruida 5432G controller, new stepper motor drivers, the same 36v stepper power supply, the same steppers, and the same laser power supply. The Ruida controller got a new 24v supply.

I’ve tracked down and squashed a lot of implementation bugs so far, from homing positions, to inverted axis, etc.

I now have two issues to track down which I’m struggling with a little. I suspect they are related.

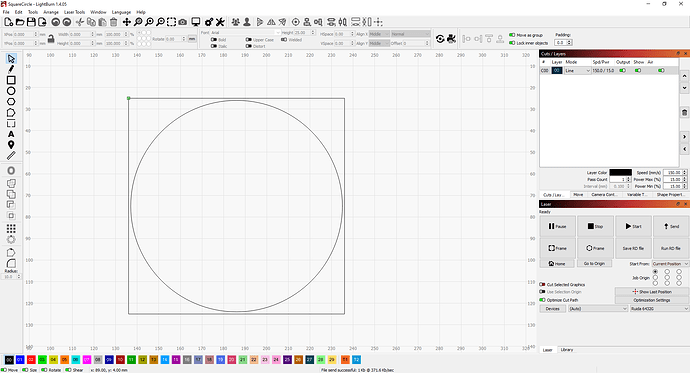

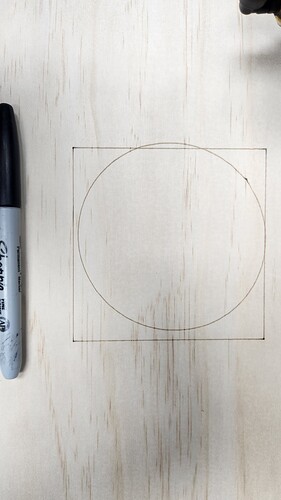

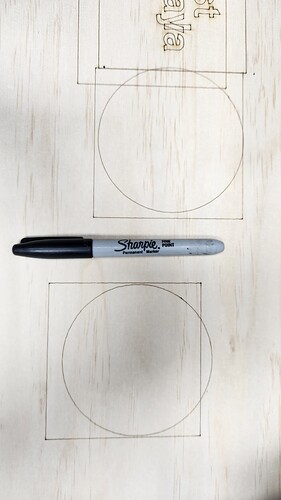

- Lines are ‘wobbly’. I’ve included a couple of photos to show what I mean. Previously I had very crisp, clean lines. The old controller did not have settings that I could investigate for re-use, however.

- I have a design with a circle contained within a square to test the ability to draw straight lines, sharp corners, and to track the position of the stepper

throughout the circle. The square and the circle, when engraved, do not align. This also happens with text, with letters overlapping unexpectedly, sometimes. This happens regardless of if I’m pressing the Start button on the PC in Lightburn, or sending the file to the controller and pressing start on the Ruida controller. The photos show a shift left, and separately a shift up.

I have tried, based on another post, adjusting the Speed Factor % setting to 50% to fix the wobbly lines. This didn’t seem to help at all.

Laser settings are 150mm/s / 15% power on a 100w laser. Changing the speed up and down doesn’t really seem to affect the outcome at all.

Other info:

- The belts are tight.

- I’ve been through the electricals a few times now, happy that they are well connected, and hopefully connected correctly…

- I didn’t have this issue with the previous controller - which wasn’t lightburn compatible.

- I tried a similar design with RDWorks, and got the same outcome / issue.