on previous (8.x) version of LB, Z-control was pretty unusable because it used absolute positioning and would not work without a focus sensor (will head-crash every time)

on 9.x, the “relative” Z move starts to be usable, BUT it seems somehow it botches with the material library.

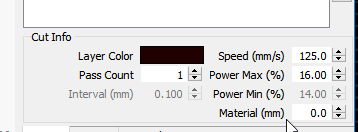

first test, i draw 3 circles of 3 different colors, assign the power from the same library element (which was cardboard 0.7mm), and set

- first color with 2mm Z-offset

- 2nd color with 4mm

- 3rd color with 6mm.

as my “normal” focus is around 7mm from top surface to the bottom of the nozzle, i don’t take a risk… on last version i crashed the honeycomb in the head… i set my focus around 4cm to be sure to emergency stop the machine if z-axis goes crazy.

run, and so far, so good, the Z is moving, in the right direction, each circle is done with the offset ok.

BUT, after that, i try to use it in “real” condition, that is setting the focus height correctly for cutting.

and, it seems that whatever you input in the Z offset value, the height of the material is taken in account : i set the Z-offset at 0, do my focus, “origin” on the keypad, start my job.

and the first thing the machine does is moving the Z-axis!!! totally not what i want!

after that, at the end of the job, the Z-height is also not restored to its initial value. so, it is impossible to run many batches of the same job without doing the focus again and again.

i’m not sure, but i believe that somehow, the “height” of the material is taken in account and ADDED to the Z-offset.

the problem is that when you assign a cut setting from the library to the color, this value is never displayed. so, you have to somehow compensate for this.

real use case : i want to engrave a 2-color plastic and then cut.

i copy the setting from “plexiglas engrave” which has a height of -1 to the scan layer

i copy the setting from “3mm plexiglas cut” which has a height of 3 to the cut layer, and then change the power to reduce it (since my material is more like 1mm tall)

both layers have Z-offset = 0

i set my focus exactly (7mm below the head)

the job run, the scan is offset Z (probably around 1mm i guess), so the engrave is bad, and after that the cut is again Z-offset 3mm, and the cut is awful and totally burned.

the only way to prevent Z-move is to disable the Z-move option in the machine settings.

can we expect to have relative Z-move without any interaction with the material height saved in the library? obviously, i will do my focus ON the material, not on the empty table!

also, it seems very important to me that whatever the Z-moves are during the job, the table must be returned at its start position at the end of the job.