Dear all,

I’m running Lightburn 1.0.06 with a Cohesion3D laserboard on my K40 laser. I want to do something exceedingly simple and use a chuck-based rotary axis to laser-cut a 3 mm diameter quartz tube (or at the very least score it evenly across the circumference so I can then cleave it cleanly). The tube is able to be cut easily with even low laser powers, but to make it all even, I would like to rotate the tube as I cut it. This is especially important because I want to keep the tube as cool as possible such that I do not get silica condensing on the inner walls of the tube (or, as glassblowers call it ‘bloom’).

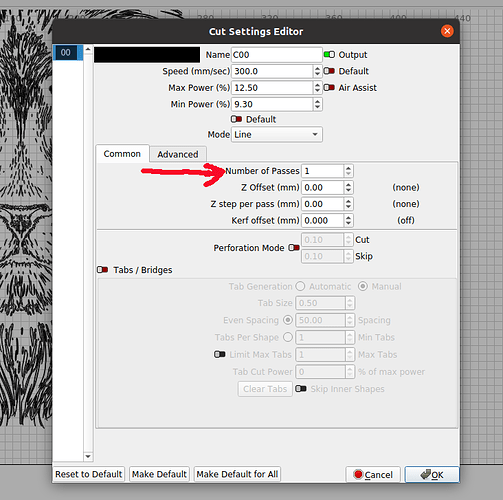

I have not yet convinced myself that I understand the workings of the rotary axis which I have plugged in to the A (gamma axis) on the laserboard with X, Y and Z also occupied, the latter for a z-table. I have followed the Cohesion3D instructions for using a rotary axis and have updated the delta_steps_per_mm accordingly in the config file. The test function for seeing the chuck rotate 360 degrees forward and then 360 degrees back also works.

My questions:

1.) If I draw a line in Lightburn in the x direction, the rotary axis does not move while the cutting takes place. The results are the same regardless of whether I give the line a small amount of thickness (dimension in the y direction), or make it zero. I want the line to only be as thick as the laser spot at the focus (give or take ablative effects etc.) Is this a problem and am I thinking about this correctly?

2.) It seems to me that the rotary axis is a replacement for the y-axis even if both are wired and both are configured to work; therefore, the laser head will only raster in the x direction as the object is being rotated. It will not move in y, since the y-axis is more or less redundant here. Is it possible to reconfigure this such that I am able to obtain rastering in the y-direction, rather than x? My x axis is longer and could accommodate a longer tube if I am able to flip this around. Can I do this in Lightburn or do I need to flip the coordinates of my bed around (and dimensions, limit switches etc.) in the Cohesion3D config file?

3.) It seems that the way Lightburn operates, and the way the underlying Gcode works, is to require precise instructions, rather than vague ones. I think the answer to this is no, however is it possible to run the rotary axis continuously while the cutting is taking place in the y-dimension, or is this too ‘vague’ to work?

All the best,

Ryan