Hi,

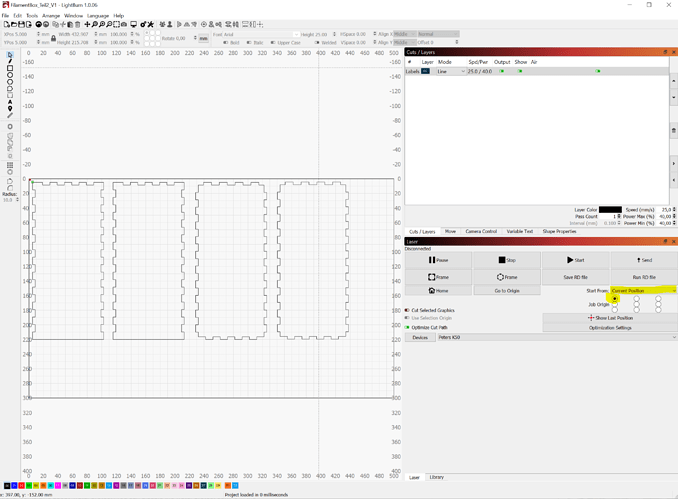

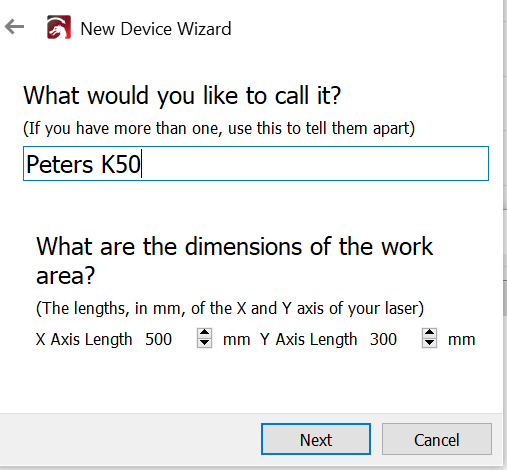

I have a 50W laser with 300x500mm cutting area. Today I tried to used there parameter “Kerf” in Lightburn 1.0.06. I set it to 0,1mm. Even if all Elements had min. 5mm space around I got the error message "frame exceeded bounds " from my machine.

After several tries I just placed a 10x10mm element at the center of the cutting area and got the same result. After setting the kerf back to 0 everything worked.

Seems to be a problem of the controller (Ryxon KT332N). Any idea how I can use the feature of light burn ? Doing it with my CAD software by “hand” would be not so nice.

thank you

Peter

This should work fine and others using Ryxon/Ruida controllers use kerf without issue.

Can you upload your .lbrn file here for review?

I have the same controller and there are none of the symptoms you describe with the kerf settings here.

Thank you for the feedback. Good to hear that maybe I am the problem and not the controller

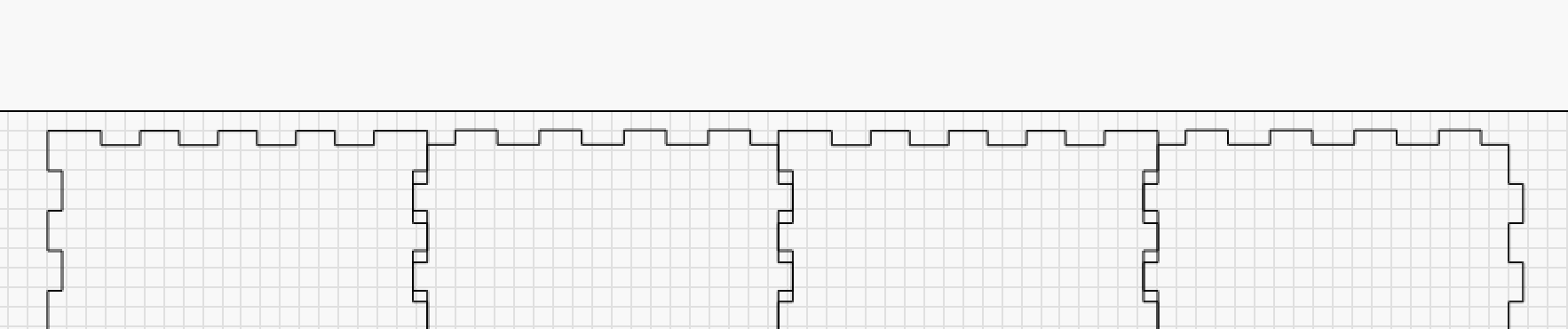

Here is one file with kerf 0.1mm which makes the trouble

FilamentBox_Teil2_V1.lbrn2 (20.6 KB)

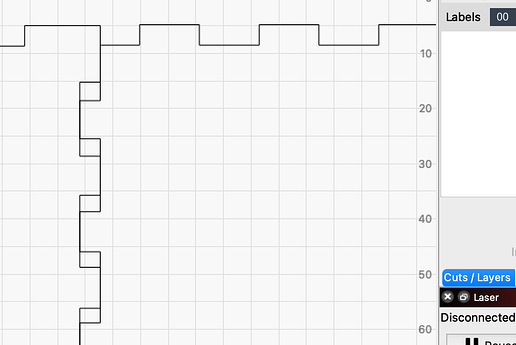

I just tested your file and there is no error message here with me. But your box parts already have a kerfs setting before you give another 0.1 kerfs, it seems a little strange.

When playing with kerf settings I can not provoke an error message in my controller.

I don’t see anything particularly strange in the file.

Some additional clarifying questions please:

- You listed your work area as 300x500 mm. I assume this is WxH. Yet the contents of your file looked like they should be in an area 500x300 mm. Can you confirm the 300x500 mm or was this a mixup?

- When do you get the “frame exceeded bounds” message? Do you get any message from LightBurn when this happens?

- How are you starting the job from LightBurn? Start or Send?

- Do you get a job preview on your laser monitor? Does it look correct there?

- Does the Preview in LightBurn look correct?

As far as I know your controller shouldn’t really be able to differentiate a job with a kerf from a design that had an offset applied.

This is also strange because this error message usually only occurs when overscan at too close a distance to the edges or too high speeds (and too little distance to the edges).

Do you use absolute coordinates?

You are right, sorry.

500mm in X-Axis and 300mm Y-Axis.

2/3)

- In Lightburn everything is fine. Simulation works.

- I send the file to the laser.

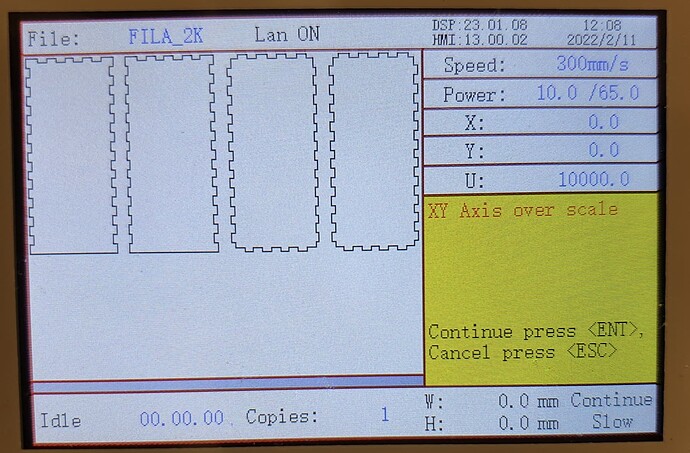

- Press the “Frame” button at the laser and get the error message ( XY Frame over size ).

- If I press “Enter” the laser show me the frame and do not touch the end switches.

- If I start the laser by the “Start/Pause” button on the controller I get the error message again and the laser do not start

- yes, and it looks good

- yes

As far as I know your controller shouldn’t really be able to differentiate a job with a kerf from a design that had an offset applied

So Lightburn does not send the kerf to the controller, it just send coordinates ?

But I just enable/disable kerf in Lightburn for this cut.

@bernd.dk Where do you see the kerf setting of the box ?

@bernd.dk

As far as I understood I do not use absolute coordinates.

“Current position” is used.

Yes. At least that is how it operates for g-code. Don’t know if this is somehow different for Ruida.

Can you try this with absolute coords?

@bernd.dk and @berainlb

Now I understand what kerf you mean. This parts you see are only parts of a box which do not direct fit together. There is a second file with the other sides which fits in this parts.

The laser is too small fall all parts

And the winner is: @berainlb and @bernd.dk

I used absolute coordinates and it works.

Thank you very much for your support.

Peter

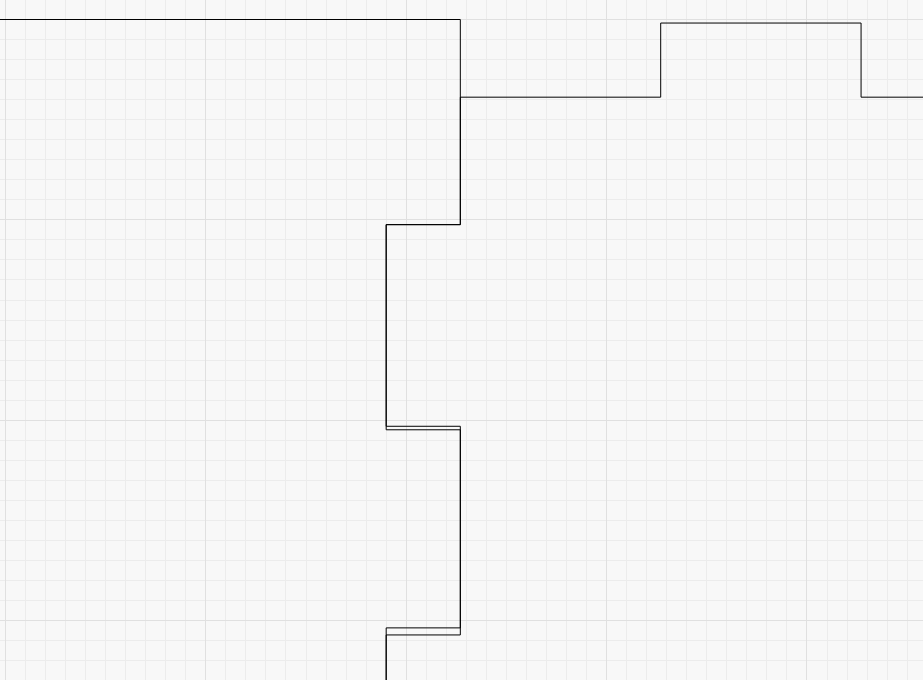

I had done the same. I realize now the difference was that you’re looking at the other extreme end with the accumulated offset whereas I was only looking at the first offset.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.