Hello again…

Now, movement is working fine, but i noticed, thet the laser doesn’t fire with equal powe on both x - and y- axis…

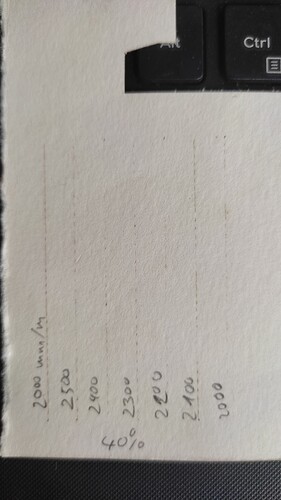

I wanted to grave a very smooth line on cardboard, just for bench marks. I did it with 3200 and 40%

On x axis it worked fine. On y axis, there is no line…

Before that I have noticed on some cuts, that y lines sometimes don’t go through. But thought it was because of the plywood fibers…

As I had problems with movement as lightburn chanched parameters randomly, I wonder if it coylul be a similar issue?

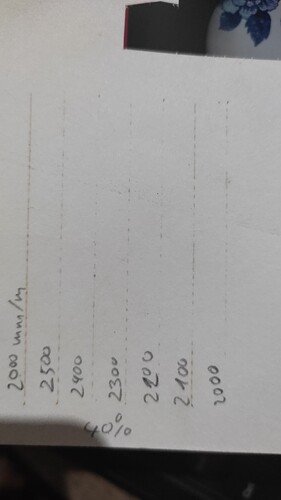

This may be due to the laser dot shape being asymmetrically wider than tall. Almost all diode laser have some asymmetry in dot shape. However, I wouldn’t expect that to cause the difference between line vs no-line on cardboard. How much slower to do you need to move to get a line to form along the Y?

Can you confirm the units for the 3200 number above? Want to make sure we’re not dealing with a units issue.

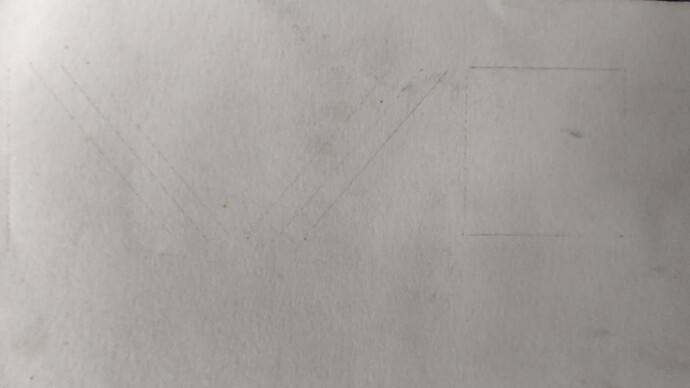

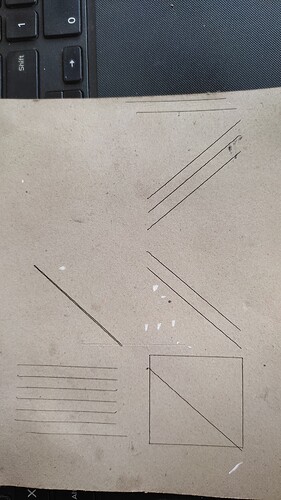

Additionally to PY’s comments, can you do a test pattern with a square and diagonal lines? To check the movement and cutting abilities.

In one case, I also had the theory if you have one axis too tight (wheels, belts) and the motor needs too much power to run, the laser power is reduced. So check the mechanics as well: Guide to mechanical adjustments and maintenance

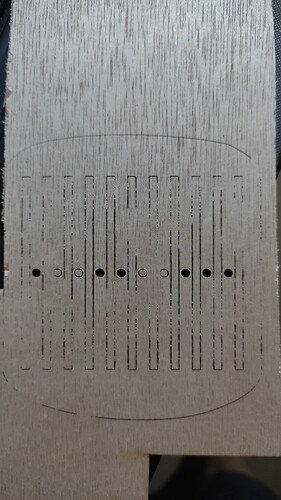

Ok… I did different tests. The main problems seems to be the cardboard. Seems it was a bit reflective… i tried another one and got good results

But… By accident one line was lasered with 2 pases, and as you can see, it is not at the same position

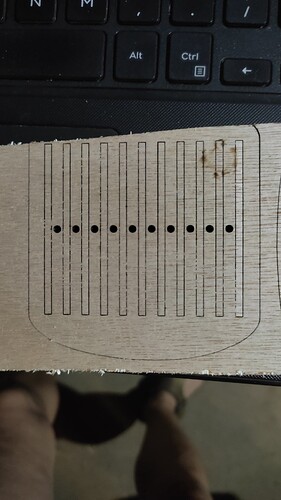

I did the belt- test and found it to tight, so I loosened it a bit. Maybe its too loose now (the diagonal lines have are a little disturbed)

First 2 imigages with the reflective cardboard, last 2 with another one. On the last the line that was supposed to do with 2 pases, but seem 2 different lines

Speed is mm/min

You definitely have a mechanical issue of some kind. Recheck belts. They should be taught without being stretched, but showing no slack. But this looks like it could be the laser module assembly not being well secured to the X gantry. Make sure you don’t have excess motion or play there. If so, adjust the eccentric nuts that are situated near the wheel axle to adjust the distance of the wheels to the railing. There should be no gap but not affect the smooth rolling of the wheels.

I tightened the belts again and its much better now. Im not sure about if it has excess motion… The wheels dont have gaps. But if I pull the laser at its down and, it moves a little forward and backward. I would say, its normal motion

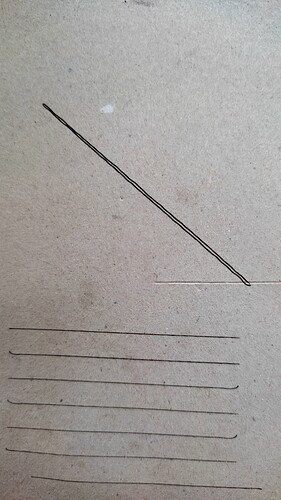

This is the 2pass diagonal cut again

That seems to look good. The nature of the burn I find interesting, though. the width of the line seems to change. Not sure if that’s just the type of material but it’s a little odd.

I did another cut…

Again the x-y issue… While horizontal cuts are fine vertical cut didn’t go through…

To me it seems to be the same as on the diagonal line. Vertical cuts seem to bee unsteady

Latest cut on plywood

Vertical lines on first cardboard

That does seem like a problem. Try one thing, can you rotate the plywood by 90 degrees and try that same burn?

I wouldn’t expect this sort of issue at 40% power. I could see this happening at very low power levels.

The other thing to check is to make sure the cable going from controller to laser module is clean at the connectors and without damage. Look for burned ends or any physical damage.

This one worked better!

Plywood ciuts were done with 600mm/min 80% 5 pases

At first look I couldn’t find damage on cable. Tomorrow I will check with better light.

Wait, are we looking at the bottom of the burn, not the top? If that case this could be perfectly expected. Materials all behave differently and your laser likely will have a direction in which it will cut better due to the dot shape.

You will need to run various cut tests to get the best balance of speed and quality.

I didn’t imagine thatvthe laser cuts better on one direction…I will try out how it might work best for me.

Thanks

As said, that is a quite common thing. You usually don’t really notice this because you should always add one pass more than is required anyhow. Because all these plywood types are not very homogeneous materials and there are areas that cut worse than others all the time. So, if you don’t want to risk unfinished projects, add another pass than you think is already enough.