Hello. I have had to replace the tube in my Blue and White Chinese 50/40w laser machine. The tube had slowly been losing power and finally fell over the edge last week.

Prior to that it was doing everything we asked of it well, if slower. Cutting, engraving wood, acrylic etc…

I have upgraded to a Reci 100w tube and ZYE myjg 100w power supply.

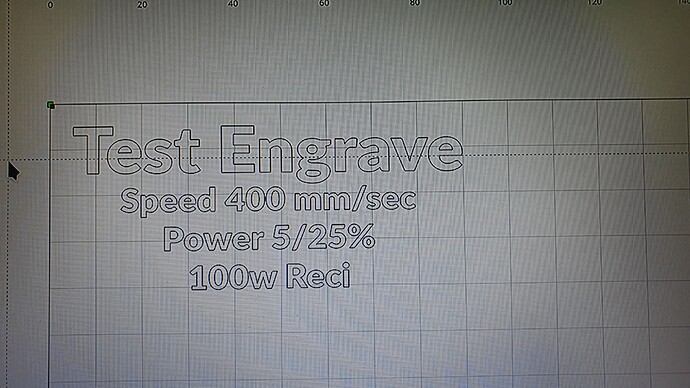

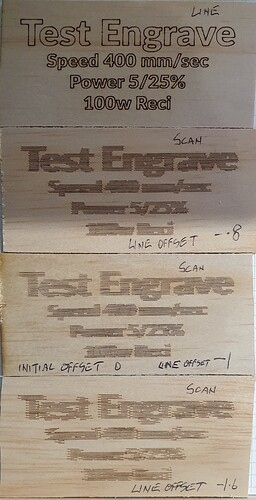

With alignments competed the machine is cutting beautifully, but engraving/scanning is a mess.

I believe that the beam ‘switch on’ is delayed as I am hearing a relay clicking in the power supply.

Turning off bidirectional scanning restores normal results but slow.

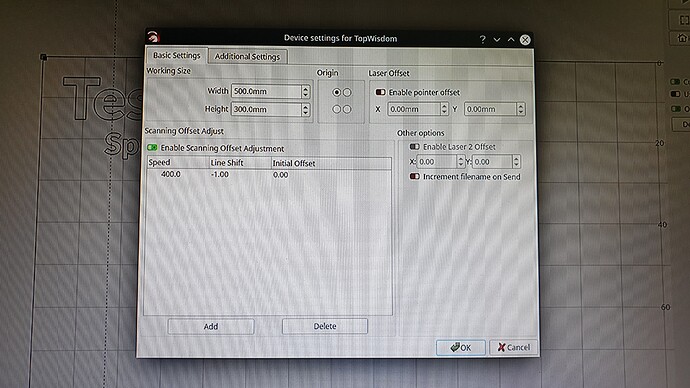

Scan offset has proven helpful, but I am missing something with results inconsistent.

I can line up the horizontal scan lines, but text in the test piece is a mess.

I am confused.  Hoping the attached pictures may help.

Hoping the attached pictures may help.

Glad to see I’m not the only one with this problem. I upgraded to a 80W tube and power supply. Even after adjusting the offsets it’s still not good and higher speeds like it use to be.

You’ll likely need to add multiple scanning offsets at various speeds to allow for proper scaling. Suggest you test at a few more increasing speeds and add those adjustments.

Thank you for your reply but yes I did set several different speed settings and the best I can get it 200mm that’s not too blurry. Also having issues with the laser not firing when doing small lines in a graphic. It will burn small text but parts of the graphic’s small lines are missing.

I solved the issue in my case. I tried the offsets with mixed and unsatisfactory results. In the end, I found that my controller/power supply wiring was incorrect. Once sorted, normal precision was restored.

I could dig out further details if you need.

Can you tell me more about your wiring problem? I have a simular issue on my TW TL-A1