For the laser being left on between cuts, make sure that you are either running GRBL 1.1f or higher, and using the “GRBL” device, or use the GRBL-M3 device for 1.1e or earlier.

Check the settings in GRBL - type $$ in the console and press enter, and check the following values:

$32 - this value is “Laser Mode” and should be 1 (you can set it by typing $32=1)

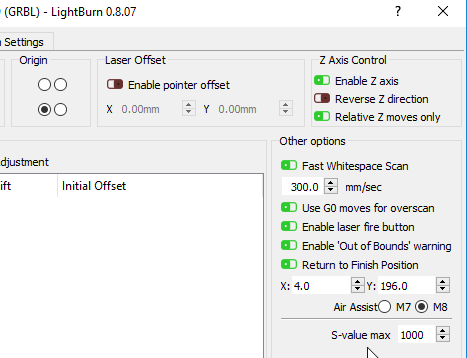

$30 - this is the number that GRBL uses to mean “maximum power”. It defaults to 1000, but lots of companies change it to 255. There’s a device setting in LightBurn that must match this number, called S-Value Max, shown here in the Device Settings in the lower right:

If either of those settings isn’t right, the beam may not turn off during travel moves.

For material settings, your best bet is to find others with the same hardware and ask. LightBurn works with man, many lasers, and what works for my 40w or 100w CO2 machines will be completely different on yours.