Hi There, I have been trying to setup my sainsmart 4030 upgraded to 6060. I have found that many articles which have different instructions for setting up a negative coordinate machine using offset values. But it appears that lightburn now has the “cnc machine” option which will automatically do the offsets for you. All articles say that the origin should be set to lower left, but the machine runs backwards when I do this. If it set the origin to right rear and set the “cnc machine” it seems to work correctly. Here are the settings that seems to run the machine in the correct directions with what seems like correct range. But after running a laser cut it tries to return to 0,0 and hits the limit switches.

I tried to clear all set GRBL settings before the latest shown settings were made to make sure my initial testing with offsets were cleared using $RST=$.

Any guidance on why the machine is hitting the limit switches after the laser runs?

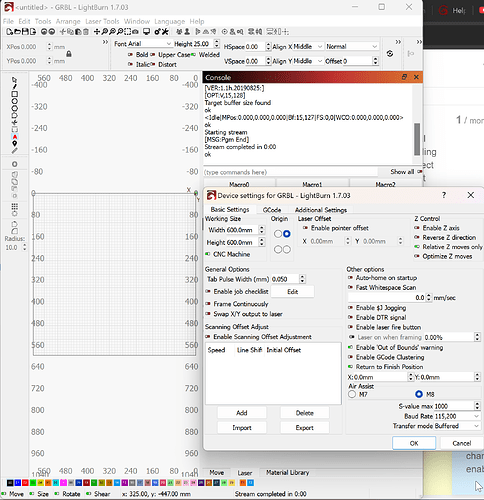

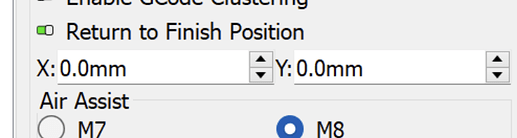

Device settings:

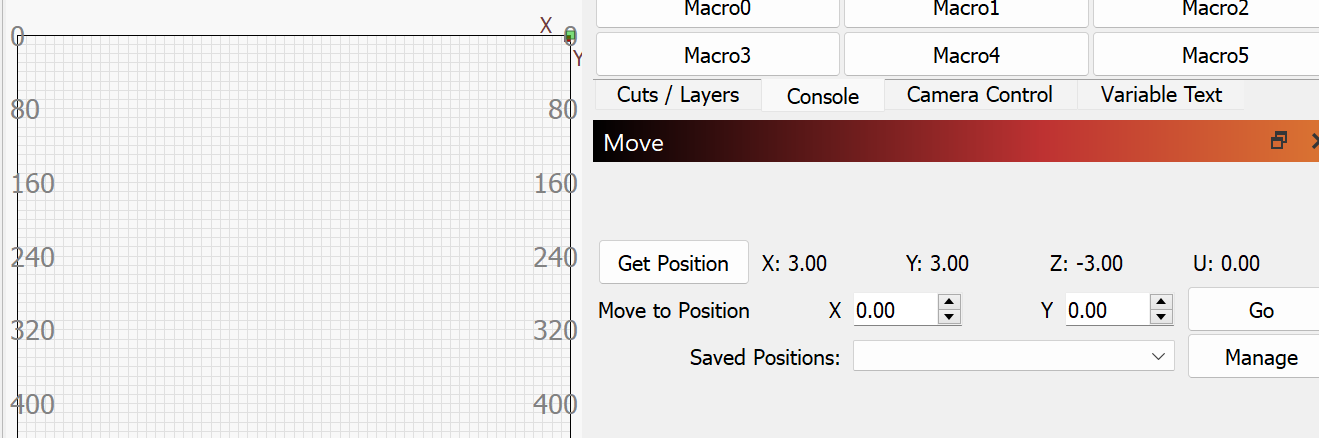

Homed get position capture with get position showing 3,3 rather 0,0 after homed:

More info.

$H

ok

<Idle|MPos:-3.000,-3.000,-3.000|Bf:15,127|FS:0,0|Ov:100,100,100>

ok

ok

ok

<Idle|MPos:-12.718,-3.000,-3.000|Bf:15,127|FS:0,0>

ok

ok

ok

<Idle|MPos:-12.718,-12.718,-3.000|Bf:15,127|FS:0,0>

ok

<Idle|MPos:-12.718,-12.718,-3.000|Bf:15,127|FS:0,0>

ok

$H

ok

$I

[VER:1.1h.20190825:]

[OPT:V,15,128]

Target buffer size found

ok

$$

$0=10

$1=25

$2=0

$3=1

$4=0

$5=0

$6=0

$10=3

$11=0.010

$12=0.002

$13=0

$20=0

$21=1

$22=1

$23=0

$24=100.000

$25=1000.000

$26=250

$27=3.000

$30=10000

$31=0

$32=0

$100=400.000

$101=400.000

$102=400.000

$110=5000.000

$111=5000.000

$112=5000.000

$120=300.000

$121=300.000

$122=300.000

$130=400.000

$131=300.000

$132=100.000

ok

$#

[G54:0.000,0.000,0.000]

[G55:0.000,0.000,0.000]

[G56:0.000,0.000,0.000]

[G57:0.000,0.000,0.000]

[G58:0.000,0.000,0.000]

[G59:0.000,0.000,0.000]

[G28:0.000,0.000,0.000]

[G30:0.000,0.000,0.000]

[G92:0.000,0.000,0.000]

[TLO:0.000]

[PRB:0.000,0.000,0.000:0]

ok

?

<Idle|MPos:-3.000,-3.000,-3.000|Bf:15,127|FS:0,0>

ok