Newbie here trying to recreate a logo. I had problems doing a trace on the logo that I was given so I had to recreate some of it. I’ve attached the file. On the globe part of the logo I did an offset on the individual pieces and I would like to fill in the offsets to create a thicker line. The curves that comprise the globe intersect with other pieces of the design and I can’t figure out how to close the curves and fill them. Is there a special way to create an offset and fill it?

Thank you

moody.lbrn (451.5 KB)

This is likely going to be a multi-step process but read through this post to get a better understanding of how line segments are joined.

Looking at the design again, would it not be easier to simply create a new circle to replace the globe instead of trying to do this with the existing disjointed circle?

I think the way you constructed it may be a problem.

‘Edit → Select open shapes’ will show what isn’t closed.

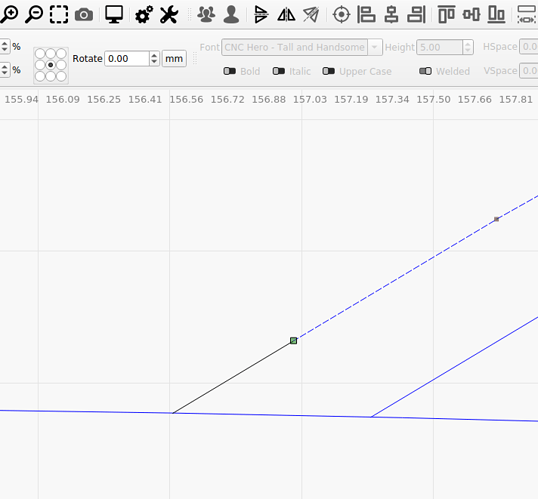

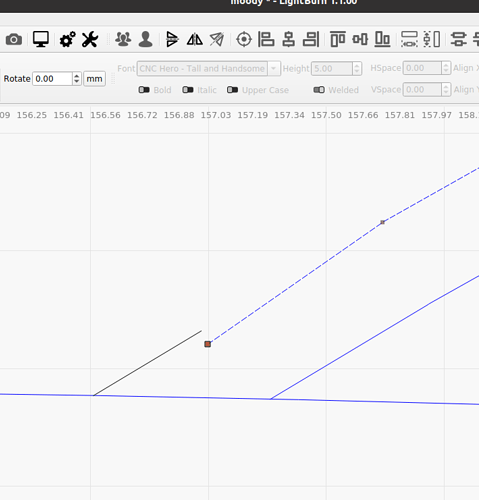

I looked at the nodes and they are not connected in a few places…

Here I zoomed in and you can see it’s not connected… The problem that’s open is the ‘circle’ construction. Did that ‘trace’ normally or did you do something else with it…?

I drug it away so you can see the segment.

How did you make the outline?

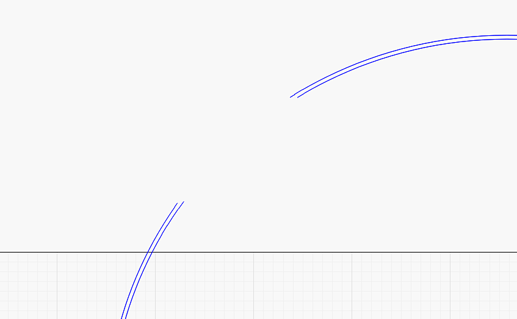

If you ‘zoom’ into the area, right of the M, the trace looks like this…

Probably not what you want, but depending on the finished product might not be visible, but it’s going to be there…

Good luck…

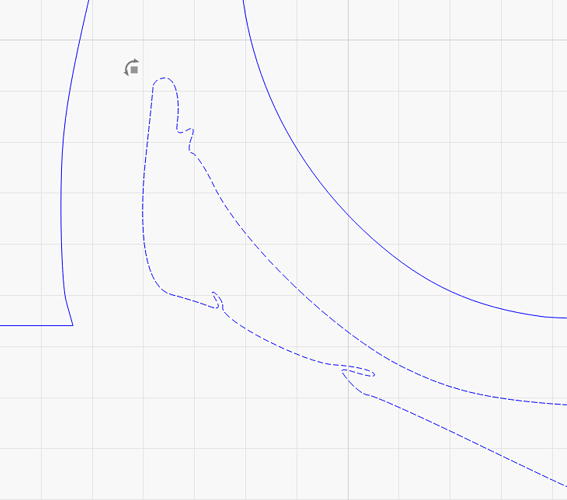

Thanks for your help guys. I did go back and close all of the paths and auto-join the different parts of the curve. But I am still unable to fill the curves.

My trace would not pick up the globe so I made my own circle and paced it over the rest of the artwork that did trace. I then deleted the parts of the circle where it overlapped the swooshes and words. What a project to pick for one of my first tries!

This is what the file now looks like. Still no filling of the offsets.

Just a thought. If I do some node editing and delete nodes that adjoin the words and swooshes will the fill then flood into the globe where I want it?

moody.lbrn (473.7 KB)

Generally if you can use the ‘weld’ or boolean functions to put this stuff together it works better.

Here’s a good video, might illustrate a better way.

![]()

Fill will only work on closed paths. Note that right now your offsets are simply lines. It’s not a closed shape.

A few approaches to fixing this.

- As @jkwilborn has pointed out, using boolean operations when making the globe might be easier. Boolean operations by definition will leave you with a closed path shape.

- You could use node editing tool to manually close the shapes.

Simplest approach in my opinion:

- draw outer circle

- draw inner circle

- select outer circle, then inner circle, then Tools->Boolean Difference. This should leave you with just a ring for the globe.

- use similar operations with the other portions of the design to “subtract” out from the globe.

Yeah, that would have definitely have been a better workflow. Trying to fix what I’ve created doesn’t seem to be working but at least I’m getting practice with node editing. Attached is my latest attempted fix. Big fail. I will start over trying your method later. Time to walk away for a bit I think.

moody.lbrn (446.5 KB)

Good strategy.

What are you envisioning for the final look? Looks like you’re trying to combine the globe with the rings? It’s not what I imagined so want to make sure I understand where you’re going in case I steer you the wrong way.

I fiddled with the node editor on your original and it would be more tedious than deleting the ‘circles’ and then creating and using a boolean operation on them. That may have been what @berainlb did on his last one, haven’t looked at it yet…

One really handy item with the boolean operations is when the objects are selected use ^B (Control + B) and a ‘boolean’ selection shows what will do what… Pretty slick…

The biggest issue I’ve had with Lightburn is because I’ve used lots of software to do similar things I have a tendency to use a ‘work flow’ creating something like I did with a similar program.

What I found is that Lightburn is more intuitive, which has lost it’s meaning, than any package I’ve ever used. It’s usually more simple than you make it. This has happened to me many times.

I started working with computers in the 70’s. First exposure to arpanet…

When you get stuck, drop a note here… Generally, we all pick up something in the discussion…

Good luck.

Honestly, I am just messing around right now. I would like to engrave the logo on a powder-coated tumbler. I’m not sure what would look best. I definitely need some practice and make mistakes so that I can get used to what looks good and what doesn’t. I am not near ready to take jobs quite yet. What do you think would look best as far as what should be a filled?

I appreciate that. I just jump right in and mess around with things and learn what works and what doesn’t/ Mostly what doesn’t. I have no graphic design experience. I’m sure you’ll be hearing again.

Thanks

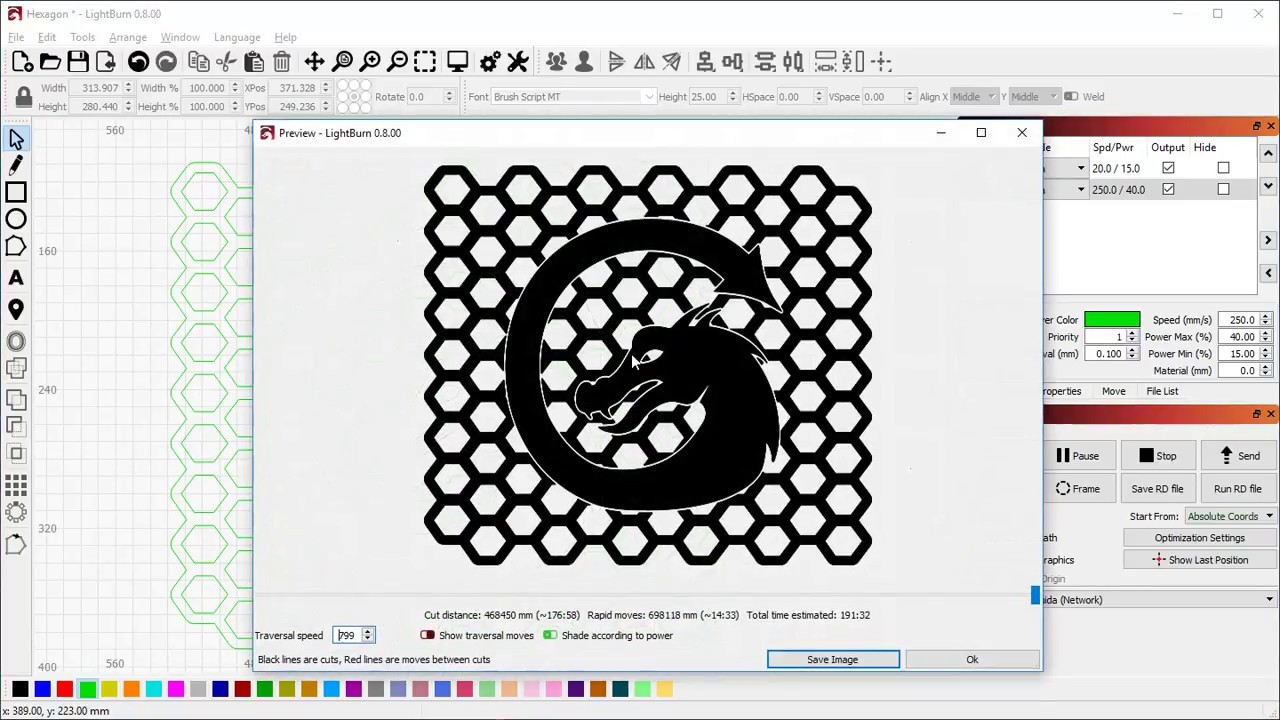

I think what @RalphU has done is tasteful. Perhaps extend the white outline effect you have on the text to be also on the rings so that there is visible separation between the rings and the globe.

That looks great. Thanks! Which parts would fill and which parts would you leave the color of the powder coating for a tumbler engrave? I’d like to keep my throw-away mugs to a minimum.

The universal dream…

I use LBT100 it’s a spray on coating for aluminum and other materials that you lase.

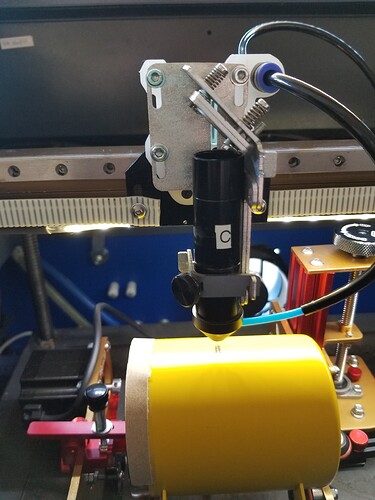

Mug for a friend with a CBD business, a vector cut on a coated mug.

They always seem to slip at one place or the other.

You can use the ‘invert’ switch on the preview to get some idea about this…

Good luck

![]()

Very nice work! My cups are RTIC powder-coated. I have a fiber laser for the stainless but I’m not going to fire up the fiber until light burn releases their fiber software. I’ll focus on learning the co2 until that time.

I asked to be able the read the galvo stuff, but they want it closed. I’m looking for another laser and I’m not sure if I want to deal with an RF co2 or a fiber laser. It would be nice to be able to read along, might help me decide.

Can’t really do it until I learn what machines Lighburn will support…

I do know that they will be supporting a jpt fiber laser. That’s what I have. I’m not going to bother learning ezcad when I’m going to be using lightburn.

I have a friend who works for the company. This will be a gift. They have no idea what they want so I’ll just have to mess around until I find something I’m satisfied with. I’ll upload my latest revision. It might work.