Hi.

Not nearly all birch plywood comes -or in this case came- from Russia, only the cheapest varities.

And lots and lots of it.

There are plenty of manufacturers in the baltic and scandinavia (and Finland, we are not actually part of either one of those regions even though we like to think so when ever it suits us), as well as in Canada, but for many reasons the price of the “western” manufacturers birch plywood has been twice or thrice the price of Russian plywood even before the invasion.

What makes the end user damn near impossible to know exactly what plywood -or where it was originally manufactured- they’re buying, is that individual sheets are rarely (if ever) stamped or stenciled, the markings are in the sides of the stacks or even just in the wrappers.

Counterfeiting the markings in timber products is also very much a thing, and a very lucrative business at that for those with somewhat questionable moral standards.

Of course, the suppliers and resellers in the west have increased the price of the remaining stocks of plywood regardless of the country of origin.

And just as it the case with most of the products we like to use, the price driven market had made us dependent of cheap(er) products from economically lower structured places, so when #2 hits the fan, our own manufacturing capacity -if it even exists anymore- can’t keep up with the demand.

So prices go up for that reason as well.

While there’s always individuals who will find ways to go around the restrictions for monetary -and in rare instances ideological- gain no matter what the restriction, and while no ban in the modern world is as effective as in paper, there is most certainly a real ban.

As there always in cases like this should.

Regardless of the agressor or aggressee.

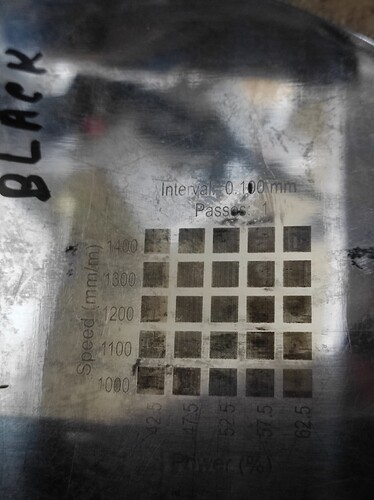

While the manufacturer can play a role in that, the composition of the stainless material plays a bigger role.

As does variety, in broad terms: whether it is austenitic, martensitic or ferritic.

Not so much directly as the composition does, but indirectly since all of those varities have their more or less dedicated uses.

Snce this method is based on manipulating the thin oxide layer that forms on the surface of the stainless material, anything and everything that affects the oxide layer, affects the transfer result as well.

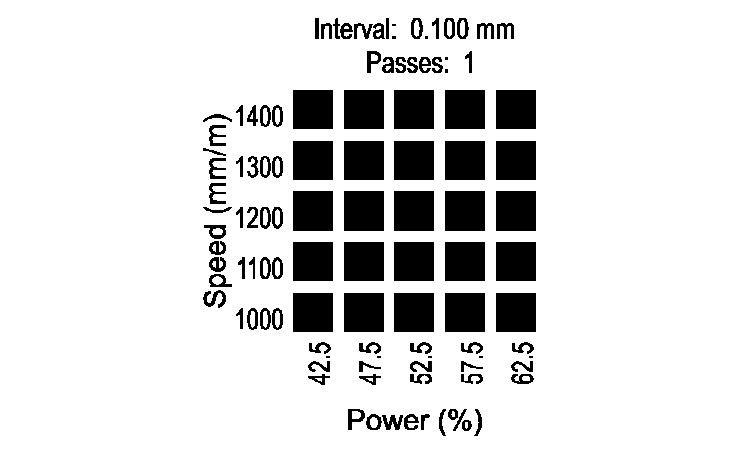

The combined material test and logo suggested earlier by @cggorman or just the logo suggested by @bernd.dk will make things much easier in the long run.

Regards,

Sam