We have a C02 laser and when we pulse to align the mirrors this is what we are getting from the laser tube. When the laser hits the first mirror we have a burn mark on our tape is 7mm wide. When the beam hits the second mirror the burn mark on our tape is 8mm wide. When the laser hits the third mirror the burn mark is10mm wide. Can someone tell me what is going on here.

One unique property of a laser is that they are collimated. Meaning the light follows a narrow pattern. They are not perfect but shouldn’t spread much unless they are being scattered by mirrors. Or what ever your firing on is burning.

My reaction is as long as you are able to calibrate the optics it doesn’t matter. The lens will take all that energy down to a point.

Do you have a TEM0 resonance on the tubes output?

![]()

We’re new to the laser crowd, so i have no idea what you are talking about. And how do i check that.

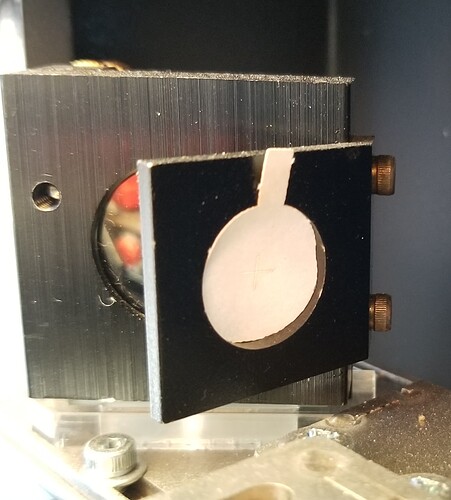

Put a target onto the m1 (mirror 1) and pulse it. Should be brown not burnt and look like TEM0 type of ‘spot’… something like this…

This just ensures the tube is working properly…

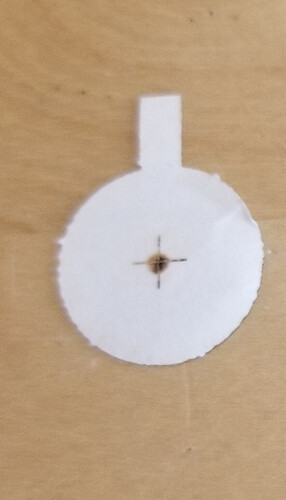

I cut these targets out of watercolor paper… there is a ‘cross’ in the middle. This is m2 …

Is this a new machine?

![]()

We have had this machine around two months. We are still playing with settings on the Lightburn program. The mark on the second and third mirrors comes out looking like an “o”. but larger on the third mirror.

The question is how is it coming out of the tube onto m1.

Here is one of my targets from m2, short and long distance… two ‘pulses’

Does it look like this?

If so, that’s not good. ![]()

![]()

Thank you for helping us out. By the way ours is like the TEM01. What does this mean.

Contact whom you purchased it and ask for a new tube… That one is toast… ![]()

Let them know how you diagnosed it, with photo of the target at the tubes output… you could post it here also… ![]()

![]()

What could have possibly caused this, it’s a 100 watt unit but our max power setting is set at 65. What would be the result if we kept using the laser, it still engraves.

Many things can cause issues like this… It usually indicates the co2 inside the tube is deteriorating. This can be from age, over current, temperature or just use. I’d expect more than a couple of months for a ‘consumable’ like a tube. That’s why I’d go back to whomever sold it to you…

Did you notice if there is a date of manufacture on the tube?

Do you have a mA meter and what kind of current do you usually run ?

![]()

I have a similar wattage tube and try to stay under around 25ma and run a compressor style chiller at 19 deg C. I’m sure others have a slightly different recommendation but everyone agrees that heat is bad for a CO2 tube.

Thank you, I’ll see if we can get a reading on the current and check for manufacture date on the tube.

We were getting a snapping sound about three weeks ago. I notice that our chiller’s hoses were kinked because of the way it was sitting. Our boss noticed a spot where the tube was arching to the housing and insulated it.

The arcing doesn’t sound good.

My chiller has an alarm that stops the beam when flow drops below some amount. You can test yours by pinching the hose. I would be surprised if it didn’t also have an alarm.

We run pretty much around 6ma.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.