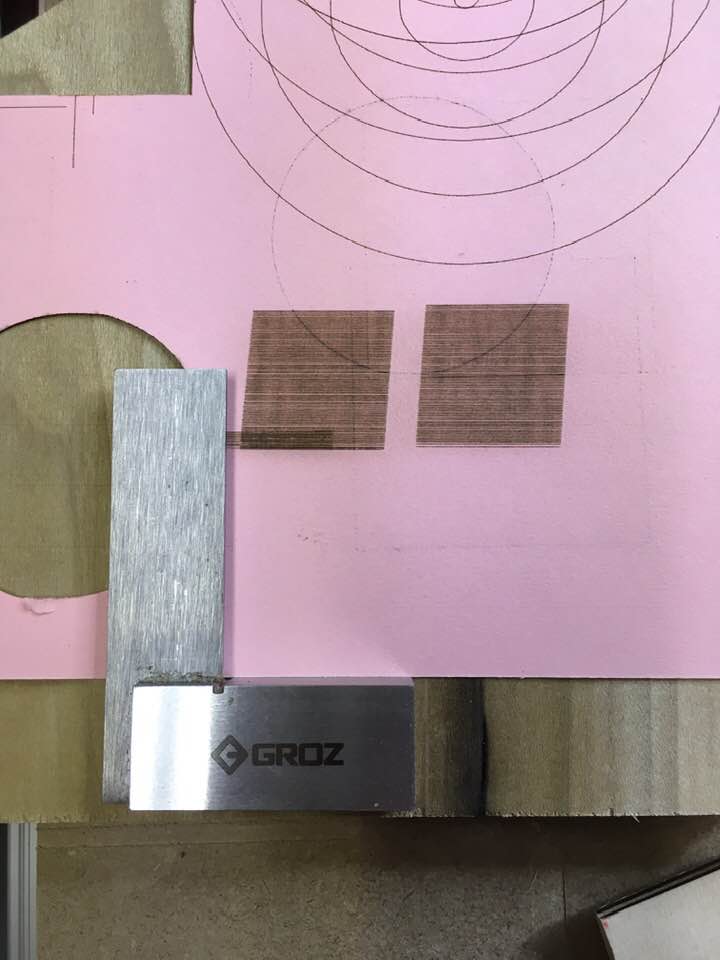

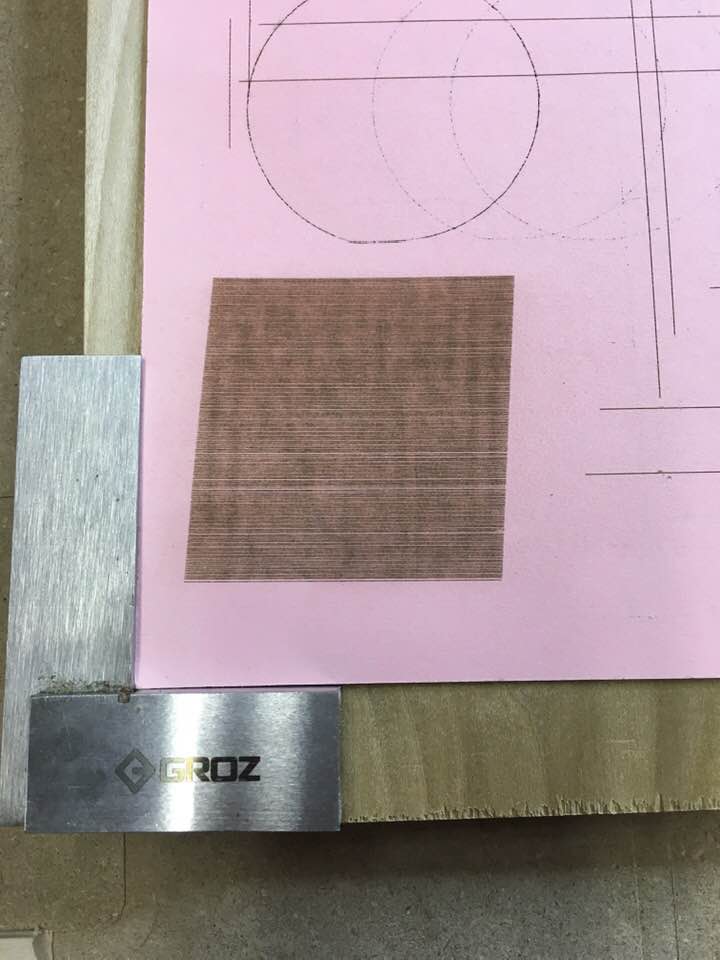

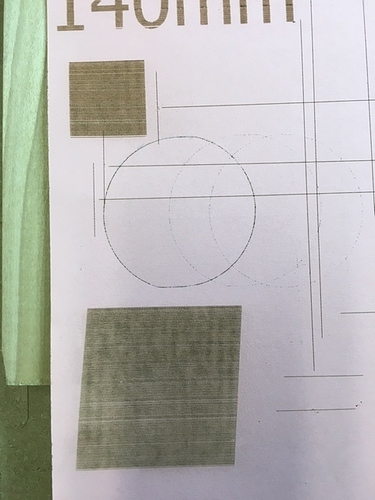

Any idea why my squares are coming out skewed.

I should add that this is only happening during scan mode. Cuts come out perfectly square.

This looks like what happens if you don’t have the correct setting in the controller for the step pulse.

You’ve not said what controller you use, so this is a guess, but with Ruida, Trocen, and most other DSP controllers there is a setting for which side of the motor step pulse actually triggers the step (called rising edge / falling edge, or leading edge / trailing edge). If that setting is wrong, when the motor changes direction it will skip a single step, and these add up over the length of the job and become skew. There are so few direction changes during a cut that it’s imperceptible.

I have a RUIDA. This started after I reset factory settings. Now just need to figure out what I need to set to correct this.

In the Machine settings for the X and Y axis will be a checkbox called “PWM Rising Edge Valid” - change that from whatever it is now, and that should do it.

Do I change it for both x and y axis?

It’s worth mentioning that "Factory Settings’ is for the controller. Whoever you bought the machine from probably changed them to match the actual machine hardware. And yes, assuming both axis are using the same type of motor driver, they should be set the same.

alright, I will give that a try and report back

Your suggestion worked. Albeit, I got some strange results when checking both the x and y axis. I enabled for just the x axis and left it disabled for y and got the results I was expecting. Otherwise my circles started to skew if both were checked.

Your circles look like you have backlash (the flat spots on top & bottom), which would more likely be a mechanical issue. The missing steps caused by toggling that switch will only happen when there’s a direction change, and it’ll only be a single step missed. If you’re running a cut, that’s one step at the top or bottom of a circle, which should be invisible. You only see it when scanning because there’s hundreds or thousands of direction changes in a row, and they add up.

I’ll need to give that some thought. There may be other things at play here.

This is a good reminder why we all need to keep a set of occasional backups of all our important laser files.

If you put your laser information, specific laser and controller information, in your profile so people can see it, maybe someone will have the same machine and controller and send you their set of backups.