This is a 3 prong issue,

1, is it necessary to build a jig to work on my Fox Alien rotary to engrave slim line pens. I have a customer wanting his logo etched into it, and fear that damage to the rollers may occur since the pen diameter is so small. Dia, will not accede 9mm, so looking at the rollers? the blank will rest well below the top of the rollers.

2, while these pens are made with epoxy? is it advisable to paint the blanks to ensure laser grabs the material much like doing clear glass for the etch?

The plan is to etch, then back fill with logo colors

3. Alternative method is to make a template with painters tape and air brush the logos on individually. then coat with CA.

in a lot of the videos I 've watched, most pens were made of wood.Some were powder coated stainless steel. but no epoxy. I find that odd unless it’s just not possible. Thank you in advance.

Ray

This will probably not end well, because generic epoxy isn’t a nice laserable material. This list of materials pertains to CO₂ lasers, but any laser that can vaporize the material will cause similar problems:

A visible-light laser will probably not deposit enough energy in a thin layer of more-or-less transparent / translucent epoxy to vaporize it. If that’s the case, then it won’t produce a clean engraving channel.

You definitely need tests on scrap pens, starting without the rotary, just to show the laser can do what you expect. If the engraving works at all, then you can worry about fitting them into the rollers.

If you test and find that you can engrave them with the laser I would recommend using a jig, again, this will depend on how far around the circumference the logo will go, with roller rotary you can only do one at a time, with a jig you can do as many as will fit your work area at once.

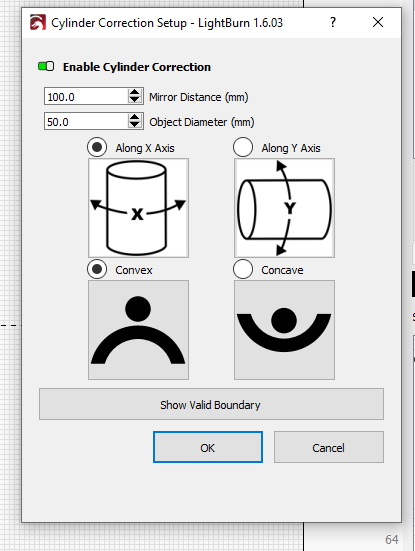

Repeat marking is the ticket. Can it be combined with cylinder correction? That would be the bomb for pens. I’ve tested cylinder on pens before, works great.

Not sure, I am waiting on my pen blanks to arrive I haven’t done pens before, but in theory it should, might have to get confirmation from someone who does pens regularly.

It’s not clear what you mean by this. In what material did this “Cylinder Correction” work great? and is that a function in your machine settings? or Lightburn?

Thanks

If you are not using a galvo, maybe ignore!

Used cylinder correction for a pen just to see how far it would wrap, if it would work on something that small. Worked pretty good. My rotary table is not set up for pens so didn’t try repeat marking with cylinder correction turned on.

.

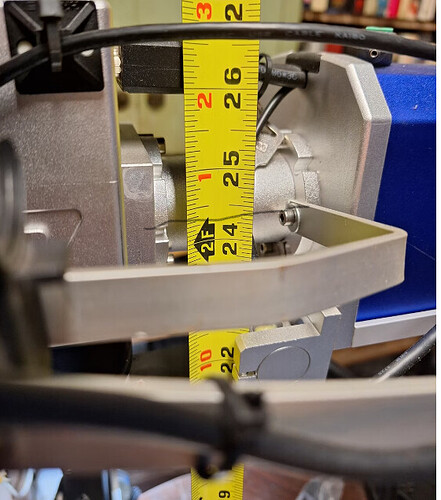

I use the measurement from the top of the object to the center of the path for mirror distance, did some tests that came out closest for me.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.