I have a Boss LS2440, I am trying to run a piece that is 30’ wide by 20" tall. i have everything set to cut from the middle.

No matter what I do I cant get this error to go away.

I also tried it from the zero position and no luck.

i read where they said it could be the speed as well, so I took my setting from 325 speed down to 100 speed. still no difference.

Am I missing something here? This seems like it could be user error!?! Haha

It’s more than likely operator error… I see it too, even though I know what causes it.

I assume you are ‘scanning’ a piece of art.

If you use the preview function with ‘show transverse moves’ it will show where the head is moving.

Somewhere you are configuring it in a way that causes it to go out of the machines work area. Generally this is overscan occurs where the head has just completed a lase, now it’s slowing down, changing directions and then has to get back up to speed before it can fire…

If possible post the .lbrn2 file so we can examine it.

What are your ‘start from’ and ‘origin’ values? They are in the laser window.

![]()

Is it really 30 feet wide: a plank sticking out way far on both sides?

If I understand the laser specs correctly, the laser platform is 40 inches wide. You cannot engrave across that entire span, because you must allow room for the laser head to decelerate to a stop on each side; that’s the “slop” area.

If you’re doing the engraving in sections on that long plank, limit each piece to maybe 30 inches to allow a 5 inch slop zone on each side.

If the workpiece is 30 inches wide, then make sure it’s really centered in the platform with equal space on each side.

Sorry its 30" wide

lake.lbrn (309.7 KB)

Does it tell you which axes…

Mine will sometimes tell me which axes is causing the problem…

Did you try the preview to see if it showed excessive overscan?

![]()

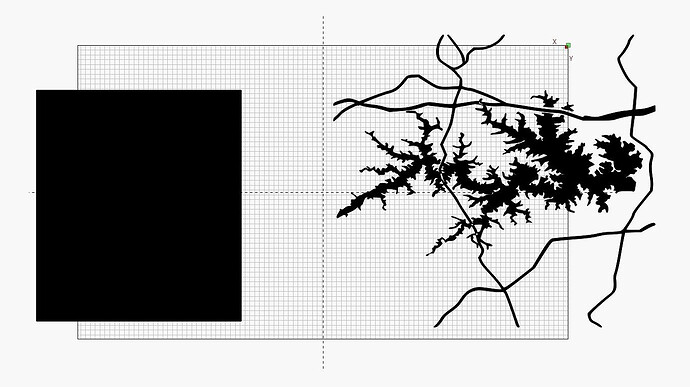

I set up a fake laser with a 40×24 inch = 1016×609 mm platform and loaded the file:

If Cut Selected Graphics is off, then the rectangle + lake will definitely be larger than the platform. I assume you select the lake and move it to the middle of the platform before doing anything else.

The lake pattern extends 605.234 mm along the Y axis. If your platform is a hard metric 600 mm (rather than the hard inch 609 mm I used), then the “slop error” is likely in the Y axis, rather than along X, because some parts cannot be reached.

If the laser really has 609 mm along the Y axis, then the lake pattern must be exactly centered to ensure no part of it lies outside the platform.

With all that set up on the fake platform and using the default speed / acceleration from my laser, it looks like it ought to work.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.