Hey there, I am using Lightburn with my 1400x900 Aeon Nova 130w Reci with a ruida 6442s-B. I am experiencing an issue when I cut smaller circles (more obvious at less than 10mm diameter) . The laser goes very slowly compared to any other shapes (ellipses and polylines with curves included). The file type and software used for its creation does not seem to change the result (if I do the circle in Lightburn it still cuts slow…) Sometimes I get jobs that involve 1000s of circles and wastes a lot of time while making it hard to estimate time as the software does not take into account the slow circle cutting. I’m sure i’m missing something here. Thanks for your help!

You likely haven’t set the preview parameters to match the ones in your machine. What’s happening is probably due to acceleration limits in the controller - they’re set to prevent the system from going too fast and losing steps, and tight corners exert more force on the motion system than gradual ones, so the machine has to go slower around them. Imagine yourself trying to to turn a city street corner at highway speed - same idea.

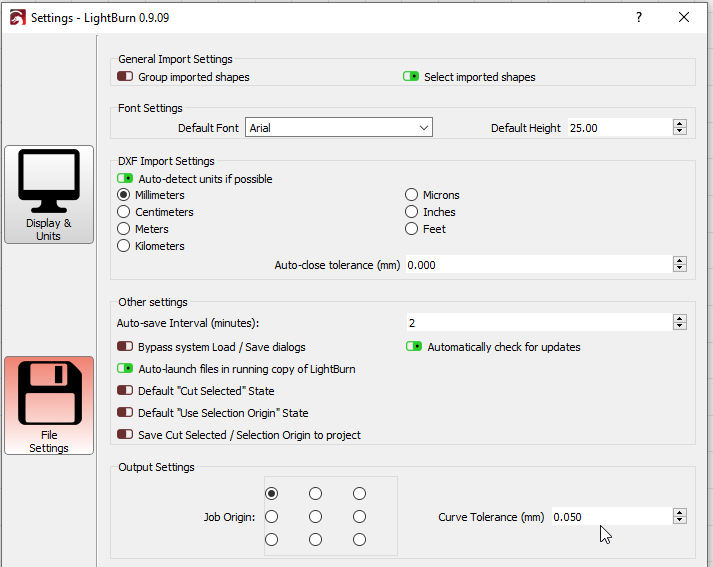

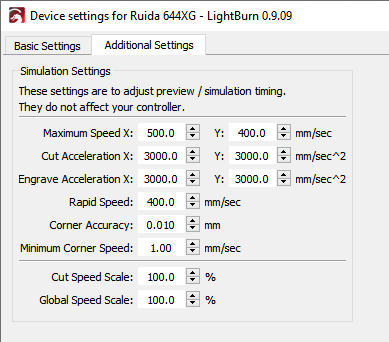

You can make the preview more accurate by adjusting the parameters in the ‘Device Settings’ Additional Settings tab to more closely match your controller settings.

Thanks for your quick reply. I understand what you mean, but my problem is not really in lightburn emulating the preview correctly, but rather the machine not taking forever in doing a small job. If the drawn circles are actually even only slightly oval, the cut will happen at the normal speed. If the circle is perfectly round, it is much much slower. I get your analogy, but the machine is definitely capable of going much faster in circles than it is going right now…

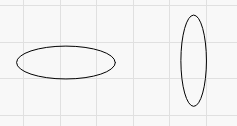

Slightly oval along which direction? (and how slight?)

Both of these would run faster than a normal circle because they’d have more room to speed up / slow down along the longer axis, but they’d still slow for the corner.

Thanks again for your reply.

The cut speed is normal if the shape is slightly oval/ellipse/stretched in any direction. By slightly I mean that a 1% difference between axes is enough for it to be cut a normal speed. It seems to really be an issue with circles.

I have included a video of the problem. Although it is not Oval vs Round, it is small shapes and small circles. The difference in speed for one circle is not much of a problem but it adds up when you are cutting lots. Here is the link to the video [https://youtu.be/4sX8n1CGZRo ]

Curve tolerance is set at 0.050mm like in your reference image.

No more ideas as to why this may be happening? This problem is too bad for me because asides from that Lighburn is nice to use. Much faster than RDWorks on the computer when dealing with larger files! Thanks!

No, I can’t say - I’ve not seen this before. RDWorks doesn’t do this? Can you email an RD file (Save to UFile) from your version of RDWorks with a couple small circles and do the same from LightBurn so I can compare them? (make the files as similar as you can)

Ok, well, this won’t be necessary, as I have solved it after some testing and tinkering. The problem was in the Machine settings. For some reason, with RD Works, my Speed factor was set to 0%, and the speed was still acceptable. The setting of a very low speed factor helps in resolving backlash issues that i find present themselves in fast small corners in a big gantry system like mine. But somehow in Lightburn the setting was slowing down the machine more. Putting it up to 10% actually brought the speed back to normal and I am happily cutting thousands of tiny holes. Thanks for your time and perhaps this helps somebody.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.