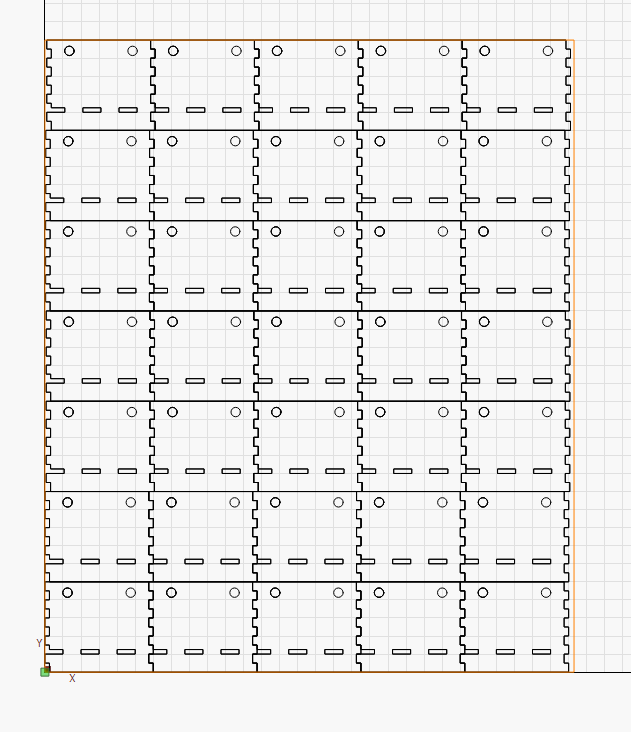

I am cutting a side pannel for a box. It has small rectangular holes in it and some circles. With same settinga rectangular holes are cut perfectly while round holes do not cut through. Does anyone know what seems to be an issue?

Hello Pavel

Could you clarify

- What machine is it

- What power module

Also could you post a small image of the lightburn design and a result picture (or post LBRN)

I am using Sculpfun S30 Pro with 10W laser. I can send you only the design at the moment. Rectangular holes are sufficiently cut, while in some cases of round holes the beam didn’t even penetrate the surface.

stranica_x.lbrn2 (299,3 KB)

Given the dimension of the circles and the shape of the diode beam is not really surprising

You might have to group circles in a different layer and give them 20% more power, 20% less speed

By the way this is a amazing use case for virtual arrays ![]()

That makes sense. Thank you ![]()

The WHY of the issue is that the square holes the laser has to stop and change directions at each corner. The circle is cut in a non-stop motion, so there is less time for the laser to burn the material.

Yes, slower and/or hotter cut on the circles.

If you have the option of minimum/maximum power for the layer, it’s likely that the circles never reach the specified speed. If this occurs, it may never reach full power…

–

With no project file of any time, we’re just guessing… as @gilaraujo advised.

![]()