3 month old OMTech 1060 24x40 100W CO2, had issued with the autofocus nearly since new. Several back and forth with OMTech, nothing permanently fixed. Disconnected the autofocus, turned off the z axis stuff if the software and did manual focus from then on.

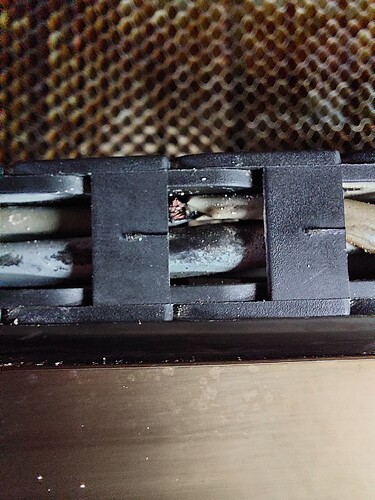

Had a need to play with the autofocus a few days ago. Turned it on, clicked the autofocus button and sparky and smoky show up inside the drag chain and the power goes off. Closer inspection shows about 6" worth of melted wiring and air line inside the drag chain. Shoot off an email to OMTech telling them about the problem.

OK, great, but I need this running tonight, so I replace the wires in their entirety, from autofocus sensor back to the controller. One for one swap using some spec grade stuff I’ve been using on my cnc builds, made for drag chain use, flexible, UV/ozone resistant industrial stuff. Everything is back together that even. A few test runs, temperature checks on the wires and we’re good to go.

Drop in the ‘needed it done today’ job, hit the button and woke to the smoke alarm telling me my shop was on fire. Yeah…this is going to be pretty. Figured a little bit of smoke, nothing big.

Until I got to the door of the shop and could see the yellow flames dancing out of the top of the engraver. Open the door, smoke to about 3’ off the ground, alarm going, exhaust fan going, and fire about 2’ out of the unit. Fire extinguisher was right behind me, so I fill the engraver with that fun to clean out white powder. Yeah…this is gonna suck to clean since the fans blew it all over the shop. Just stood there, wondering what happened, staring at the machine I just put back together and had running just fine. Guess I’ll clean it up and see what happened. Waited until it was cool, and went back into the house.

Inbox has a "“We’ll send replacement parts right out” from OMTech, to which I reply “Yeah, don’t worry about it, the engraver caught fire and is pretty much out of the picture for the future”. A few back and forth, but since I put in the new wires, they won’t cover anything. Pretty much what would have happened if I put in the wires THEY sent me, so there is no warranty to worry about. Know that once you put a sticker on the front, or change the air pump and put in a solenoid or swap out the anemic exhaust fan (like all of us probably have), you have just voided the warranty, and OMTech won’t touch it. Understand that up front before you even ask. If you turned your back on the machine, left the room, or fell asleep…cardinal rule broken, and you’re SOL with regards to warrant, so don’t even ask. You can lie. I could have lied. I didn’t, and “I” get to fix my own machine. No good deed and all that.

Fortunately, everything in that machine is available online, either AMZ or EBY or a hundred other sources. Linear bearings, 15mm HD belt, proximity sensors, wire, motors, pumps, hoses…all cheap and assembled by sub-NASCAR IQ folks. This happened on a Saturday morning, and it was back up and running the following Friday. Unfortunately, it’s about $700 that I didn’t have to spend on fixing a 3mo old machine. But it is what it is, and it was what it was. If you come in to the need to fix things, broken, worn out, small toasty-q happens, the parts you’ll find are much better than what came with it. Hell, the belt is metal reinforced this go-round.

After action: Fire was caused by the final ‘cut out’ stage of a long engraving process. The material (laser ready acrylic sheets, specially designed for engraving) had a lot of smoke build up under the honeycomb bed. Every now and then you’d see the fire on wood…this was no different, other than the concentration. The 310cfm bilge fan could not keep up with the 15psi air supply pushing the smoke down, and the smoke flashed over. The constant cutting (126 circles were being cut, aka 63ea 3" rings) made too much smoke, she reached the wrong concentration and went poof. And kept poofing until things didn’t unpoof. The big metal scraps pan on the bed of the engraver was clean before we started, the honeycomb was clean, the knife supports were clean. Just the gas ignited and stayed lit.

Prevention: Higher velocity exhaust fan, onboard fire sensor and extinguishers (made for under car hoods, whodathunkit) and a pair of thermal fuses to shut the machine down if it gets over 130 under the hood. Also, put a 4" pancake fan under the bed, off the side facing the center to help disperse the fumes and blow them towards the bigger fan in the back. And, lastly, purchased a replacement, different type of extinguisher for the shop.

#1 Do NOT leave your machine unattended.

#2 Do NOT modify your machine in any way if you want to maintain your warranty.

#3 Do NOT forget to have a networked smoke and fire detector so you can get notification wherever you stay if you’re not watching your machine. (read #1 again) One in the shop, one in the attached garage and one inside that wall which is the living room…all tied together

#4 Do NOT skimp on your purchase of a fire extinguisher.

#5 Please don’t follow my example of ‘I need it now, I’ll fix it’ unless you don’t care about the under warranty damage you fixed on your own and own a great fire extinguisher and smoke detectors.

Your mileage might vary, remove clothes before ironing, objects in mirrors and all that stuff.

burnt wires in the chain tray

So much happiness in one photo

one week after the fire