Since last week I own a Sculpfun S9 with Air Assist and a 500mmx500mm Honeycomb (Sculpfuns official one is only 400x400 but including the frame, work area is only 350x350) because I want to build something like this for my Warhammer miniatures:

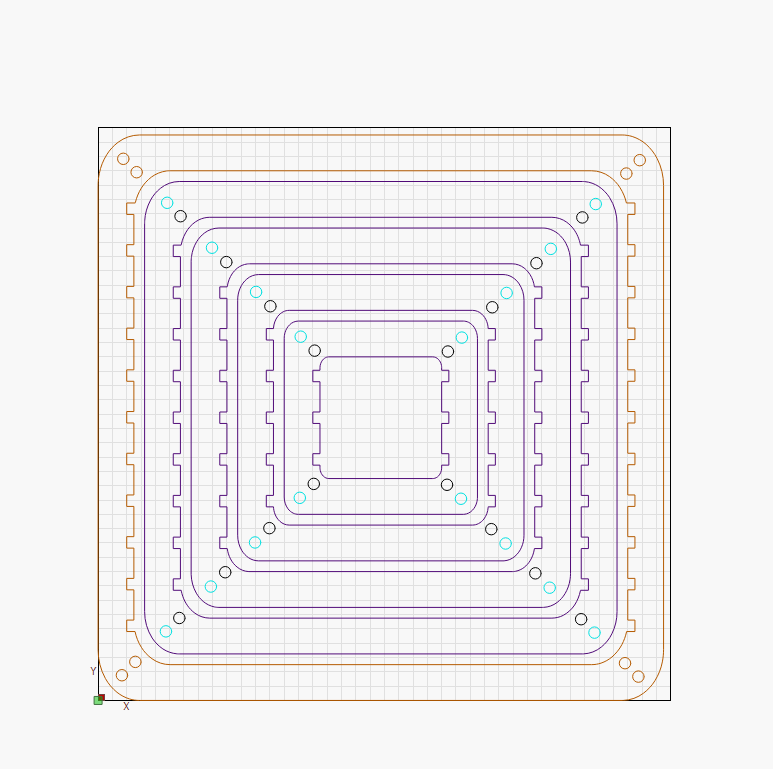

I built the design in LightBurn. It is 395mm x 395mm, so it uses almost the whole area.

I ran several tests. Managed to cut small 10mm Poplar Plywood at the beginning but had trouble with cutting through the bigger pieces. I went down to 8mm Poplar Plywood but I ruined about 5 sheets of plywood already by now.

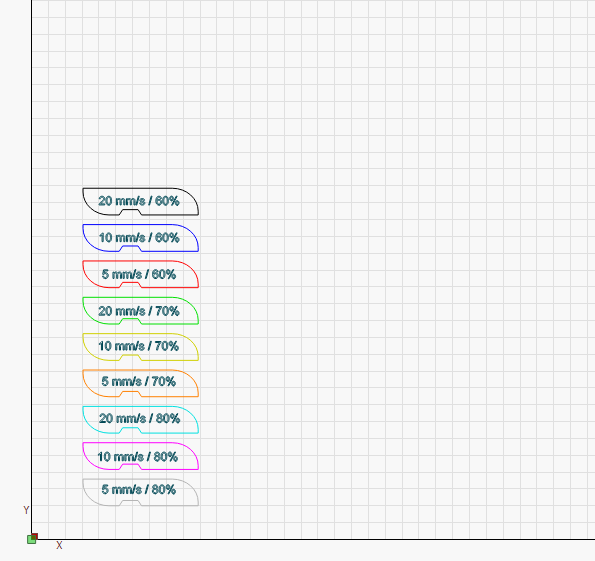

Yesterday I ran tests with cutting small pieces at 60 to 80% power at 5mm/s, 10mm/s and 20mm/s with 20 passes where the cleanest results (with least charring) were 80% at 20mm/s and 70% at 10mm/s.

So I put up the whole piece again and it ended up not getting through in most places.

I do not think it is related to a dirty laser so much, but more to the size of the object. Because my smaller pieces are mostly ok, but bigger pieces not so much. Or maybe I was just unlucky 10 times hitting glue pockets. My other theory is, that if I cut a small circle say 20 times in a row the material will still be hot and behave differently than if I cut a big piece where it takes 90 seconds until it reaches the same cutting point again.

I managed to cut the whole thing almost perfectly at 70%, 20ms and 60 (!) passes the day before, but it takes around 12 hours for a complete sheet and I do not want to go to bed with the laser still running in my basement (side note: did anyone ever have a fire issue btw? I usually go down to check on it every hour or so. One time I had the issue that the laser was stuck in one place, that seemed kinda dangerous, I think it was related to a loose cable).

The 80%, 20ms, 20 passes setting that worked for the small piece would have brought it down to 4 hours, but as I said, did not cut through.

So what I tried was just turning it around and tried to adjust the positioning of the piece to cut it from the backside, but I found it impossible to stay exactly on the lines. Is there a good way to achieve exact cutting from the backside? Did anyone do that successfully already? If I have only a few cuts that didnt go through I will carefully cut them with a cutting knife from the back. I tried a dremel but couldnt make a straight line with it.

My last issue is this. The air assist forces me to move the starting point a bit to the right and I just noticed yesterday that one of the outer frames is cut off about 1 or 2 mm on the right side and does not fit snug onto the other outer frame that I was able to cut by now. So it seems to have hit the inner right frame of the laser slightly. Now If I move the wood a bit to the left, chance is that the hose of the air assist is making it bounce at the left inner frame of the laser. So if I stop the laser I cannot risk to go back to the origin because when I start again, the next line is offset by 1 or 2 mm. So I am thinking about either telling LightBurn that my workspace is only 395mm by 395mm and not 400x400 or by moving my cutting starting point to the machine origin point. I did honestly not think I would run into so many issues. It is fun to craft something, but also kinda frustrating with all the small and big issues I run into.