Are the displayed values stable? The mA meters on the lps has to sample… it needs to be a stable reading to be trusted.

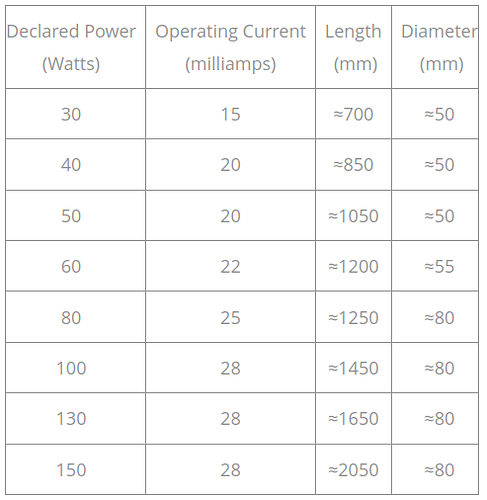

Ensure you really have a 60W tube… It’s based on length with a dc excited co2 or glass tube co2. If your tube diameter is 55mm, then it’s length needs to be ~1200mm to produce 60W. Mine was labeled 50W and was 880mm in length… it measured 43W… not 50W as advertised.

Not so obvious here, but a K40 is rated at 40W but it’s tube length, ~700mm is only that of a 30W device. If you run 20mA on a K40, thinking it’s a 40W tube, you are running it around 25% over it’s maximum rated current. Many set the power to 18mA, so it lases at 18mA anytime if lases. This is also 20% over the maximum current value of 15mA for a 30W tube. The main failure here, is the analog tube is driven like a ssl (diode).

Most of these machines, such as mine, is just about a meter wide, you can’t shoehorn a 1m tube in the machine anyway.

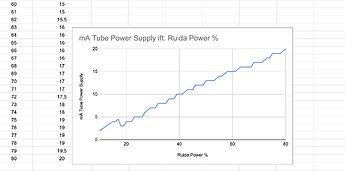

If you use percentage power, based on mA, it’s not really accurate, so to speak… Most of us have found there is a limit, below the maximum tube current that gives maximum output wattage of the device. Many assume twice the current, twice the output power, but we can see that isn’t the case.

A lot of this has to do with a co2 tube being a negative resistance device, meaning an increase in voltage doesn’t directly relate to an increase in current. In other words Ohms law doesn’t apply with these devices.

If you set it up to 50% power based on a mA reading, you’re likely setting it to percentage current, not percentage of it’s output power.

Either way, setting up the lps to only supply your selected maximum current or wattage out. It is then you have it calibrated for percent control from Lightburn (or any other software). In any case, it’s not absolutely linear, but it’s close enough. It’s not like we have a choice, as it’s all we have.

A lot of this I don’t buy into… If you need a 100W of power, you’d be dumb to use a 100W machine, as a 130 or 150W would run cooler or with less current. Like a stereo, if you needed 20W of power for the job, you’d be dumb to buy a 20W amplifier… you’d likely pick up a 30W or more so you wouldn’t be driving it at maximum.

If you run it within it’s specifications, it should do fine… you may need 100%, I have, and I’ve used it. I didn’t buy a 40W because I needed a 40W. I do need about 30W do do most operation.

If I buy a car that will do 100m/h, but the dealer tells you don’t drive it over 60 if you want it to last… I’d call bs on that… This is how you make something cheap and pass it off with bogus values… it’s corrected by stating don’t run it where it’s rated.

Most good tubes advise you of it’s life along with a working current and a maximum or don’t exceed current. Many also have lives in the 8k to 10k hour ranges, they also don’t tell you not to run it above 60%…

I cut pretty consistently at @70%, but push it up as I need it. However I expect a reasonable tube life even at 80 or 90%.

I notice @bernd.dk has wattage on his chart, is that measured or assumed?

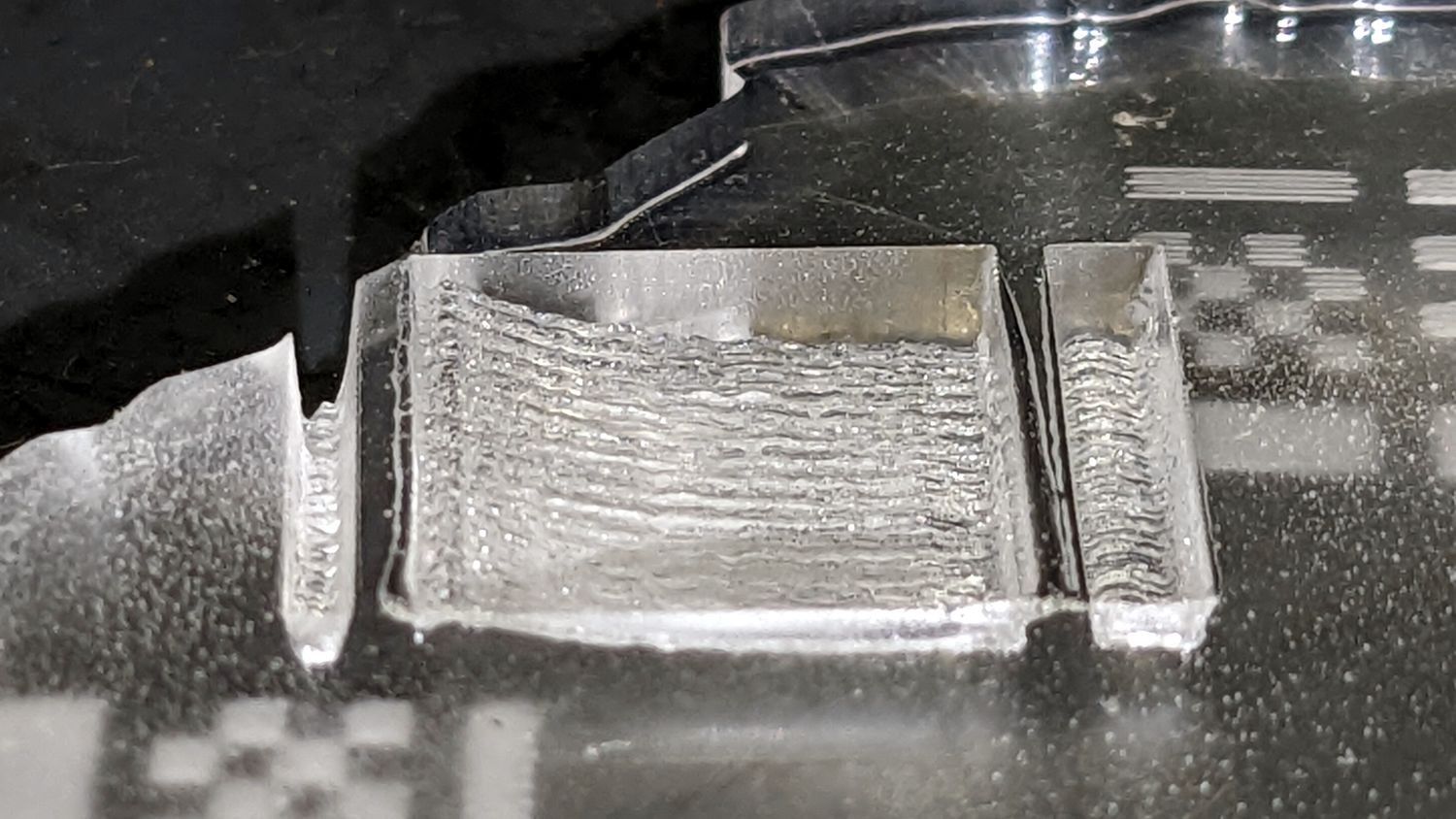

I do mine and take watt meter readings at each step… it’s time consuming, but I get a kick out of it and a good idea of how my tube is performing.

I’m not an electrical engineer or a physicist, but I’ve spent about >55 years fiddling with electronics … What I can measure I believe.

Good luck