Hello, I’ve just been testing my newly built laser cutter, and my accuracy, homing and alignment tests all worked fine, and provided consistent results.

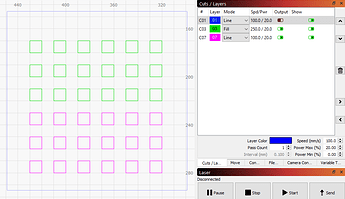

However whilst trying to cut my first test shape, I noticed some of the lines from different layers did not line up. It seems that layers with higher speeds result in X axis “skew” - even though slower speeds produce perfectly square cuts.

This can be shown in the test cut below, shown with the design/layers. The top set of squares are skewed, whilst the lower and outer squares are orthogonal. It seems that this may be caused by software or controller settings, rather than the hardware - but I can’t figure out what setting is wrong. Any ideas what it may be caused by?

(Sorry the test is on a random form I had lying around, couldn’t find a blank sheet of paper)