Hello. I am brand new to laser engraving. I have a Comgrow Comgow Z1 10w laser and am using Lightburn 1.2.01. I think I have something set up incorrectly. My issue is that the coordinates in Lightburn do not match to my laser. When Lightburn shows my laser at X0 Y0, the laser is not at 0,0. It is in the very corner of the machine, not the corner of the workspace. How do I correct this?

How are you differentiating these? Can you elaborate a bit on what you’re seeing that makes you think something is incorrect?

Does your machine have limit switches and go through a homing cycle when first powered on?

If so, to what corner does it home?

I do have limit switches on my machine and the machine does home upon start up to the lower front corner. (It homes all the way to the very corner of the machine, not to 0,0.)

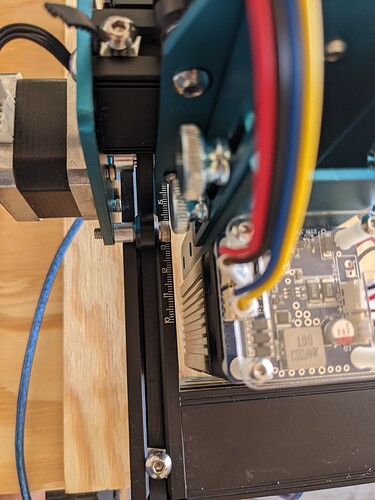

I can tell something is wrong because I am trying to burn a grid for the entire workspace on my spoil board. When i go to frame the project, the bottom of the frame is along the bottom of the machine, not the bottom of the workspace along the 0 axis. Here is a picture of where my laser homes to and begins the project when i use absolute coordinates as the starting point. You can see the laser is below the 0 mark.

Okay. Basically you’re saying the location to which it rests after home doesn’t match the physical indication markers printed on the rails?

There are a few ways to approach this:

- Just take the measurement markers as indicative of location and not absolute. This is probably the easiest approach. Note that in your picture that even if the front of the laser module falls below the 0 marker that the lens is probably fairly closely aligned to that position.

- Attempt to relocate the limit switches so that final resting position is more precisely aligned to markers. Alternatively, modify the component that comes into contacts with the switches to extend that portion so that it comes into contact sooner. This doesn’t work if you’re already too close. This is probably the most robust method of adjusting this if you can’t live with the first option.

- You could potentially attempt to adjust some GRBL configurations to pull-off farther/closer to homing switches to make up for the difference. $27 sets the amount of pull-off but is shared between all axes.

Thank you so much! I tried the second solution and that did help.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.