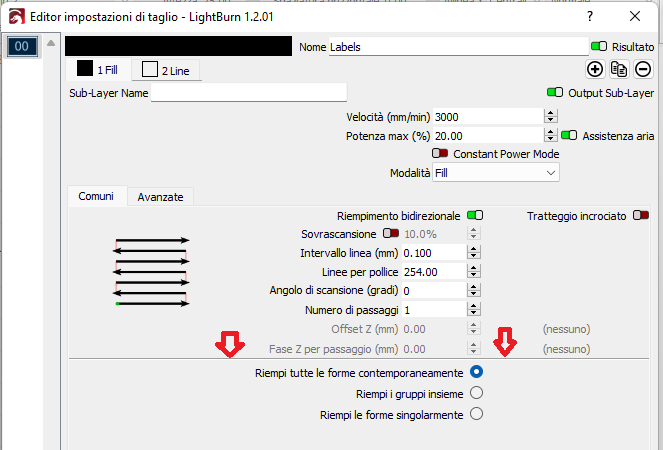

You need to scroll a bit more, It appeared to be next setting. English would also help.

If nothing else: try to enable “pass through”.

Again: posting your source and resulting NC would help.

You need to scroll a bit more, It appeared to be next setting. English would also help.

If nothing else: try to enable “pass through”.

Again: posting your source and resulting NC would help.