I added a switch to top of the front panel to select which driver to use for the Y-axis. Select Gantry or Rotary.

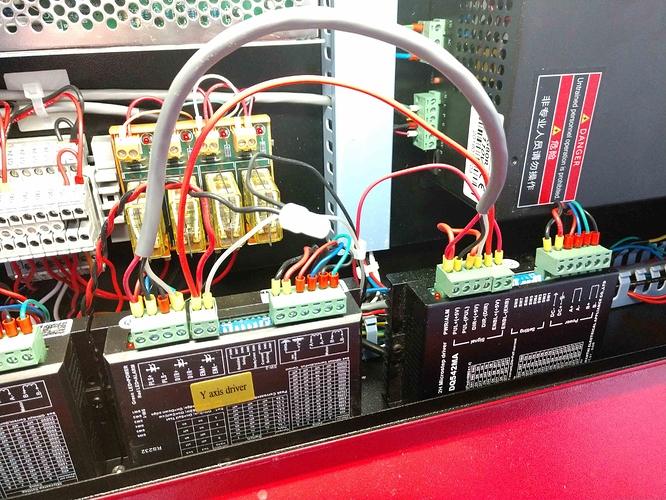

The three wires between the drives are from the switch. Black is 5V- (Com on the SPDT switch), Red from gantry selected (ENA-), White from rotary selected (ENA-). The ENA+ on both drives are connected to 5V+. The drive is enabled when the ENA input is an open circuit.

The step and direction are paralleled to both drives.

With this setup I can jog the gantry over the rotary attachment where it needs to be. Select the rotary drive with the switch. Select rotary enable in the LB software and burn the job. When finished, disable rotary in the software and switch back to gantry on the front panel. Everything is back to normal.