Good Day All, I am hoping someone here has some expertise that perhaps I can use. I have a Neje 2S Max 40W laser. (810mmx460mm) up to this point I have had no need to lock it down into position because up to this point I have only been doing 1 ofs anything. I have just been asked to make 180 coasters - while one at a time works I would certainly like to be able to do 6 /12/ 18/24 at a time if possible - and to be able to repeat the process up to 180 … my thought was bolt the laser down now (has to be repeatable) get a board and cut holes into the board for placement of the graphics to go on the coasters (they are all the same fortunately) - I wondered if anyone has done this type of work? Created a template pattern? Has any pointers? Any and All help is appreciated

Your approach sounds fine. You could potentially get away with not having discrete holes for each coaster. Imagine an L shaped jig where you pack a row of coasters against the inside corner of the L. Then you could just create stacks of coasters butted up against each other edge to edge. Assuming all the coasters are the same size this would keep them all equidistant and would save you the extra travel distance that the individual holders would take.

You may want to block off the top and right to prevent any movement or lay down something underneath the coasters that prevents slip.

As long as the relationship of the laser to the jig doesn’t change your engraving should be repeatable.

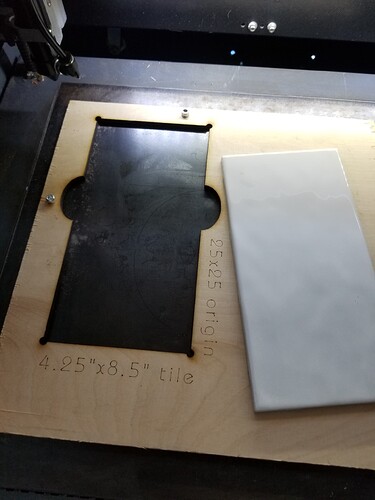

Well, i solved this in one simply way, i cutted a 3mm plywood a little bigger than coasters i need to engrave, then i remove the cutted part, put the coaster inside the hole, focused the laser on the coaster then i done the job

Thanks Berainlb! I had not thought of that but it certainly would minimize travel and give me what I need between the coasters and I can line them up at the start of the job - Thank You!

Thank You Roberto, this was part of my original thought so that I create 1 template and done but then if you look at the post above it may be something else you an use as well! Thank You for your reply!

I have locating holes in the bed of my China Blue. They were marked by the laser before being drilled and I keep them in a template directory for making new templates.

I do the locating holes on a piece of plywood. Put in M5 screws and place them in the holes. I then cut the shape of the object(s) I’m using using absolute coordinates.

Theses ‘shapes’ are kept in a template file as tool layers and ‘imported’ when needed for a project.

This is 12"x12" mirror…

I have one for coasters (no picture ![]() ) that is a 3x3 grid and a smaller coaster with a 4x3 grid.

) that is a 3x3 grid and a smaller coaster with a 4x3 grid.

With a template they will ‘snap’ into the center of the tool layer. Making easy changes or variations to a job. Makes it easy to to do batches…

I’m sure you’ll figure it out… but we’re always around…

Good luck.

![]()

Thank You Jack! Much appreciated…I like that idea with the screws for placement … Good Stuff!

I made a set of 45 challenge coins for my work unit. There were on 1.5" round wood blanks. Agree that one-off was easy, but to repeatedly produce consistent quality without a lot of re-tooling time was essential. 180 pcs - you want to minimize re-tool effort for sure.

I mounted a scrap board over the bed of my laser, then fixed a 3mm (1/8th inch) balsa sheet over the top of that. I cut out the first two holes (+.4 mm larger for insert/removal) to test, and after proof of concept I added 8 more, in two rows. I ran the Head of the coin on the left column and the Tail of the coin on the right. Once setup, the job ran smoothly for both the sides. Yes, I did take 15 passes to cut the jig pattern - I wanted to make sure 100% that the plugs would come out w/o fuss. It took a little while but the results were spot on.

art coin aplha-new jig.lbrn2 (561.8 KB)

LA Hobby Guy has a free template for burning coasters.

Thanks for all of the input folks it is much appreciated! What I ended up doing was to put 6 coasters on the page - each on a diff layer - each with a circle around the graphic which allows me to center the image on the coasters. Turning off and on each layer I center them on the coasters, once all 6 of them are done I convert the circle to a T1 line so it does not etch and run the job. Takes approx 1hr 20mins to do all 6 on my laser (I KNOW I too wish it was much faster ![]() ) but it gets them done! Have 140 done so far this way … it is working! - so Thank You to Each of you who replied it was all helpful!

) but it gets them done! Have 140 done so far this way … it is working! - so Thank You to Each of you who replied it was all helpful!