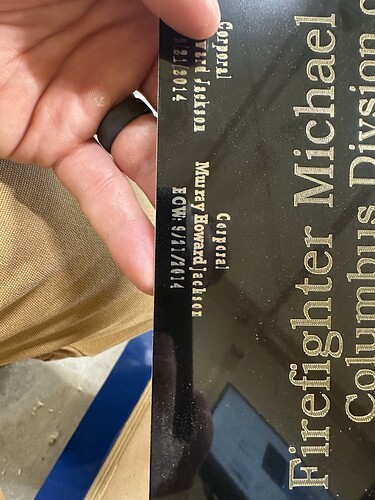

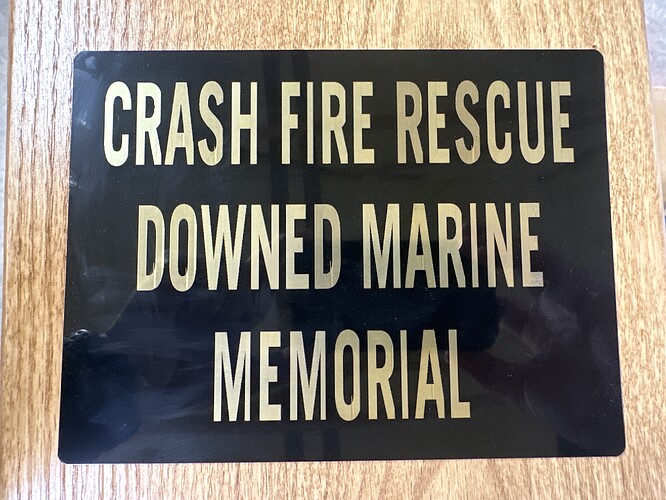

I’m attempting to make some name plates for a plaque but am having issues with the letters not being completely formed. I have tried multiple fonts, enable constant power, changed line intervals and anything else I can think of but it’s still not working. Any suggestions would be great!

I’m using a Jtech 24w laser on a shapeoko 5 if that makes any difference. Thank you!!!

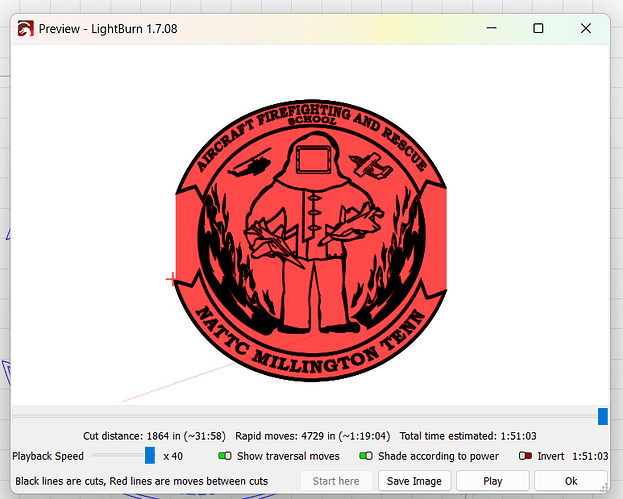

What does your preview show?

Take screen shots with SHIFT+WIN+S, then come back here and post them with CTR+V

What are your layer and machine settings?

What is your major movement axis? - I appear that your metal may be moving - is the laser head or the wire harness catching on the metal?

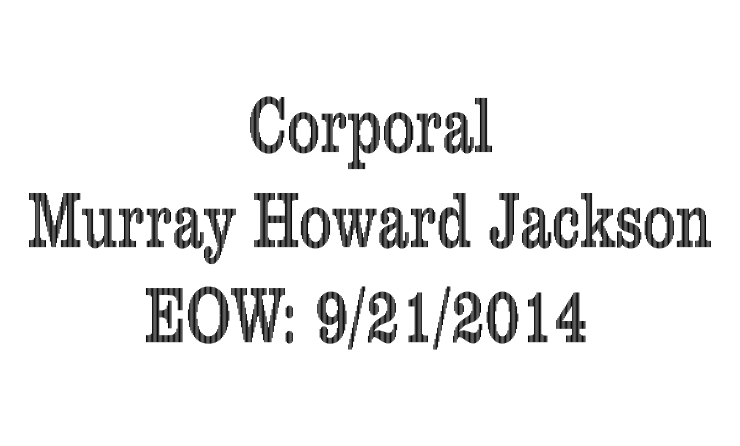

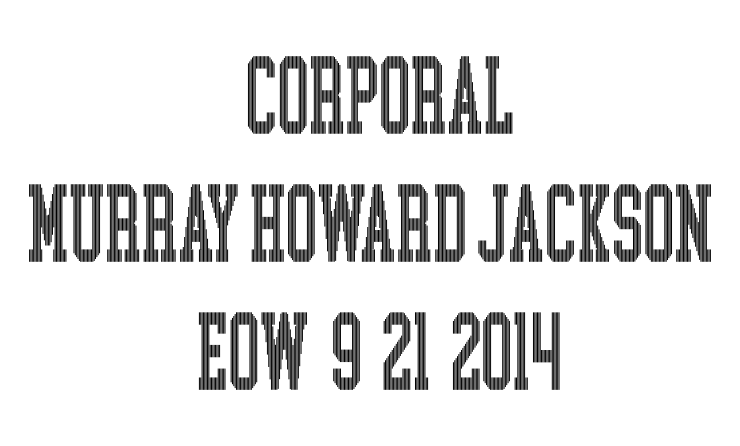

The material is not moving, it’s taped down when it’s running, I am running it at a 90 degree scan angle so I would assume if it would of been moving it would effect more the top/bottom but I could be wrong. I’m only running it at 10 in/min so a very slow rate and not much motion is being generated from that speed I feel. Here are the previews, they all turn out, this is two types of font I’ve attempted to use for this project. I did a larger one the other day and had similar results on some letters but that it was due to using flood fill so I turned that off. Now I’m at a loss as to what it could be.

Yep, I agree something is not right…

First thing is to turn the scan angle back to 00. Please try the design on disposable cardboard (Amazon, pizza or USPS priority box) - turn the power down to about 30% and watch out for smolder until you get the test power set right.

You may be able to widen your scan interval a bit more. Try around 200 LPI vs 300 LPI. Soften your focus by increasing the distance between head and material by 10% +/-

This looks like backlash to me on the X-axis. Somewhere you’re losing motion. I’d suggest doing a full mechanical review to eliminate as much backlash as possible.

To test, change the fill strategy to “Fill all shapes at once”. If backlash is indeed the problem this should relegate the issue to only one entire side of the design.

I have ran it and fill all shapes at ones and it only effected the last n on Johnson, I will go back through and make sure everything is moving smoothly and live the machine. Thanks for the advice!

I ran the file on some cardboard, as well as some wood and the letters seem to be complete without any issue. I changed the line interval from 300 to 200 that didn’t seem to make a difference. If my machine was missing steps I would assume that it would happen on all material types. Right???

Ok, the software does not seem to be the source of the error. Now, it’s time to dive into your mechanicals. The gantry is catching, the drag chain is catching, you have a loose set screw or a wonky bearing.

Show us your preview screen (TV set icon)

The images above are the preview screens, just the saved images. I did find a work around but I’m not sure what’s causing it with the wording. Idk if it’s because the text is so small or what. My job origin was originally bottom left and the laser engraving would start on the right side of the wording (so the N in Johnson would be the first letter) and work towards the left side of the material. I would then overlay a single letter n over the half completed one, then move the job origin over to the bottom right, move the laser to the appropriate location and run the single letter. It would still start from the right side of the n but would engrave the whole thing. No I also ran an image but didn’t have anything missing from it and I used bottom left as the origin and it would start on the right side???

After zooming in I apparently did have the same issue as the ribbon was not completed entirely but so small unless you knew you were looking for it, you would never know. Not sure, my thoughts are the laser is not firing early enough and is just missing those gcode lines. I feel like if it was an external source that would cause inconsistent misuses and the results would not be repeatable.

I thought it was already established that this is backlash issue on X axis. You can see in the horizontal scan version of the text that the bottom line is askew. That’s indicative of the same problem. I assume that was the first line scanned. It looks askew because that’s the axis where you’re losing motion. The vertical scan looks compressed because you’re scanning over the same vertical line multiple times due to loss of motion in X.

The “Fill all shapes at once” showed only one section on the right as the issue because you’re losing motion only once there. Since the entire fill is done in a single direction (I assume leftward) you don’t repeat the loss of motion.

Similarly, the image burn is inherently run in a single direction so showed the same type of artifact.

Have you reviewed the machine for backlash?

There is a button on the preview screen that will show you traversal moves in a light red color. That red color will show you what the software expects to happen. If the error is not present in the preview, ipso Facto, it is a machine error rather than a software issue.

… Yes, Berainb has it correct.

How would I go about checking if there is any backlash on the machine?

I see what you guys are saying that it is a machine issue, since the image preview is showing what it should be doing. I guess I thought it was more of an external issue that was creating the backlash which is what confused me as to why it would be repeated. If either you or @berainlb could try and explain how I would check for backlash I would appreciate it.

You already have plenty of evidence for it. But with the power off try moving the laser head back and forth left and right. Right as you are reversing direction if there is any movement in the head without accompanied movement at the motor then that is backlash. If your machine is configured to be rigid when powered on then testing that way may be more productive. Note that loose pinion gears at the motor are a common source of backlash. The amount of backlash will be very small, equivalent to the distance you’re missing in each character.

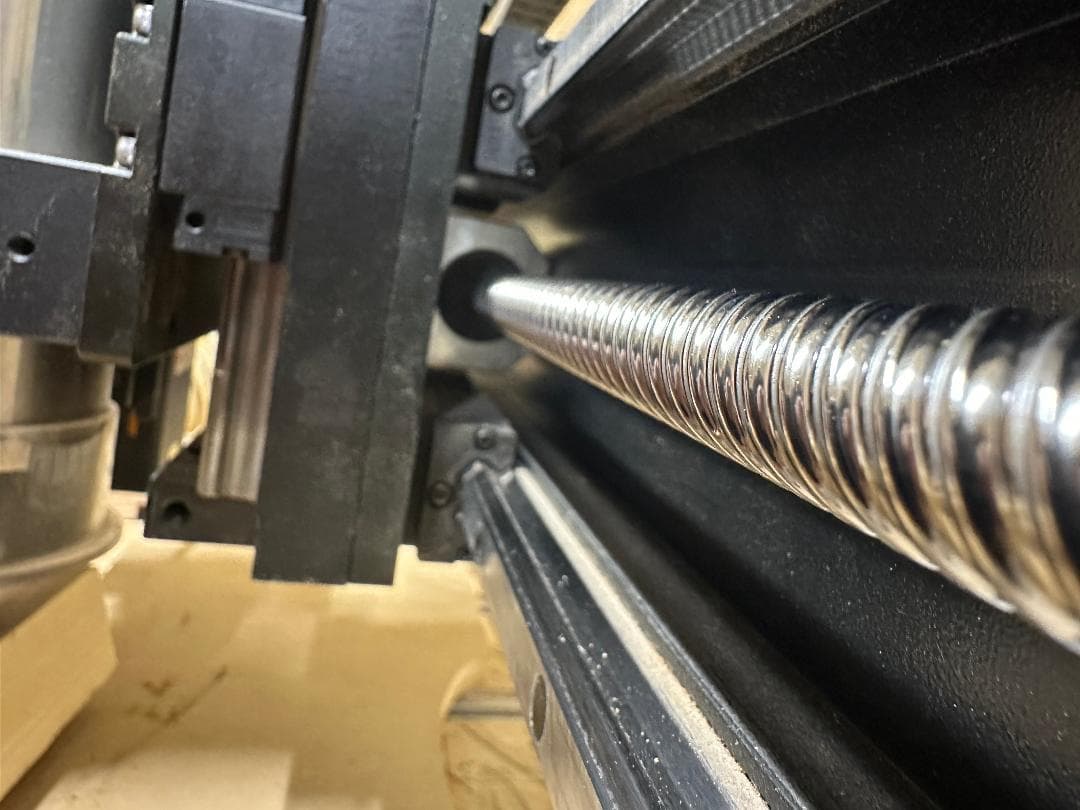

Ok, so I did some research and another individual had issues with backlash on their shapeoko also, I took off the z axis and found the same four screws highlighted below loose. I tightened the screws but also slowed down the acceleration (not sure if this was necessary) but it produced the text without any issue! Thank you for all of your help!!!

That’s great. I’m curious. What do those screws hold in? Is that what’s holding the plate to the ballscrew?

It looks like it secures the x axis plate to the silver piece that’s controlling movement from this ballscrew.

Got it. Makes sense that you’d get backlash if that piece were loose. Glad you were able to isolate it.

Thank you for sharing the solution after you discovered it. There are a few Shapeoko 5s in the hands of staff at LightBurn. I’m sure we’ll see this more than once.

Thanks again!