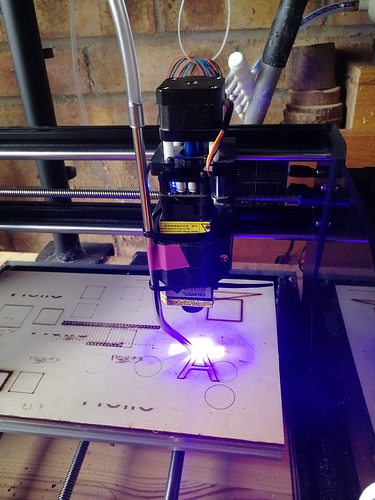

I added air assist to my 3.5w diode laser with the hope that it would cut perhaps 2mm wood.

I initially borrowed a fellow forum members 3d printer skills to obtain an adapter to fit the laser but this delivered the airflow a little too high and it was so noisy due to the diameter of the inlet.

So I needed to change the noise issue and so I used a metal drinking straw which I feel directs the air better and increases the psi(?) as it’s a smaller outlet (5mm instead of 10mm).

The noise is now gone (just a hum from the air pump) so I can now sit with the machine. Phew.

Best of all however is the improvement… I managed to cut 4mm PLY with my 3.5w laser

Details:

100mm/min

100% power

4 passes

I think I can tweak those numbers too.