I don’t know what is going on with Lightburn, but it’s giving me a massive headache. I am centering my pieces in my 400mm x 400mm workspace. I’m using an Atomstack A20 Pro with a 20watt diode laser. I am centering the laser on my pieces, and I’m using “Current Position” on the center of my piece. If I run the job, it will run fine, and then return to the starting position. If I decide to run it again for another pass, it will move my laser module way below the current position and start from there. And it does this until I close Lightburn down and reopen it. Anyone else having this problem? It’s driving me nuts. Materials are not free, and I’ve gone through a few things that are not fixable now.

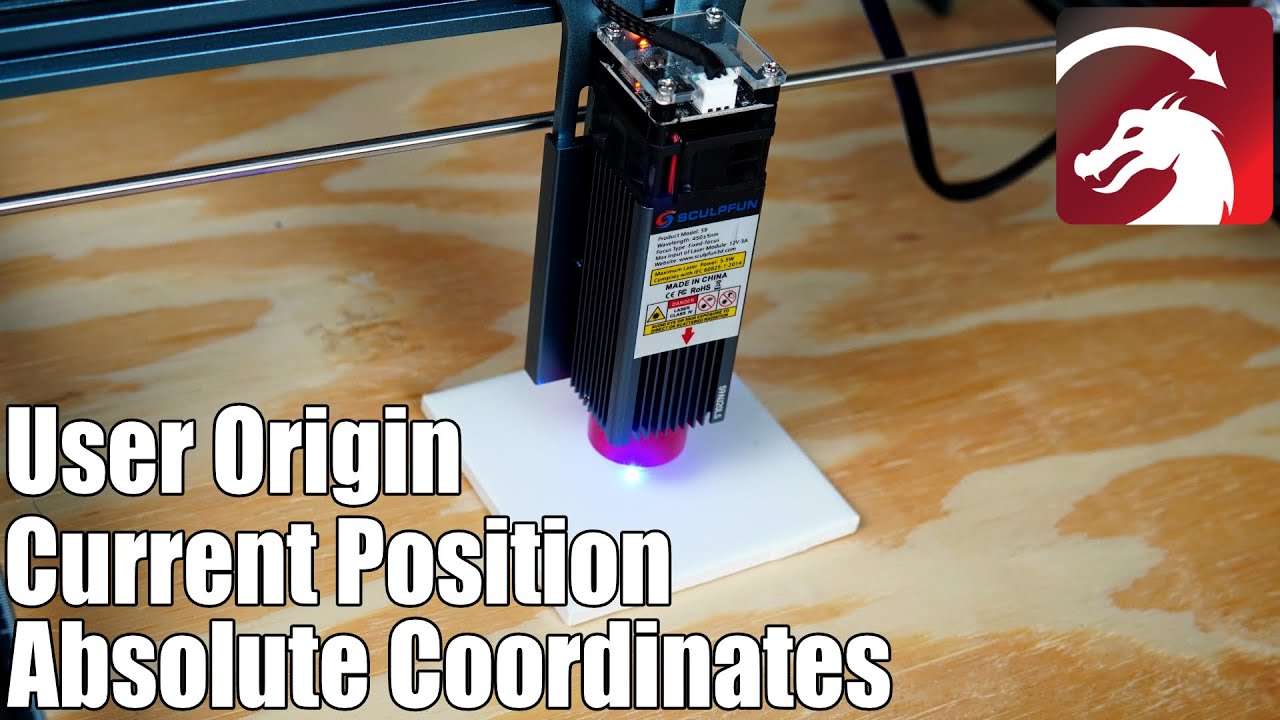

I’ve watched that video several times. I use “Current Position” just as described in the video, but the software isn’t following what is shown in the video. I should be able to manually move my laser module to the center of my stock and then use "Current Position to start the job from Lightburn, and it works for the first one. But unless I close lightburn and reopen it, and then rehome my laser, it won’t work again.

I’d like to invite the Sculpfun to tell us where it thinks it is when it thinks it’s restarting correctly. If you set your laser power to 0% or 0.5% you won’t lose any more material while troubleshooting.

If you’re so inclined, after a fresh restart, and just before your first engraving, please capture your LightBurn workspace with a screen capture tool, then request the following reports by entering these commands in the Console window in LightBurn:

$#

?

Press enter after each request.

These short reports should verify that the origin and workspace information in the Sculpfun matches the workspace.

Immediately after the engraving, capture the screen again and request the same reports. Then restart your engraving. I believe (and hope) we’ll see what’s driving the unanticipated behavior.

Just before your first engraving, are you physically pulling the engrave head off the origin and over to the center of your workpiece or are you jogging it over with the buttons in the move window? The jog buttons allow LightBurn to count steps. A physical move outside LightBurn won’t be counted.

The homing operation resets any error introduced with lost motion or uncounted steps.

Hopefully we’ll see conflicting information between the screen shots and the reports.

I’d like to catch a bug. ![]()

Thank you. I will do a test here soon and report back with what you’ve requested. I appreciate the help. And I’m absent minded sometimes. I never even thought to run a test pass on engravings at 2% power before running the real pass first. But I will replicate the software issue and report back. OH, and that’s the other thing I wanted to mention. For some reason, when I fire the laser at 2% and move it with the jog controls in ligthburn to get center on my stock, the laser won’t stay on. It automatically turns off after two or three seconds. It didn’t do that with my last laser engraver.

I’d have to check the release notes to find out for certain. It may be intentional to shut the laser off after a few seconds of no motion to reduce the risk of accidental fire.

It could also be related to how the jog move is requested in GCode by LightBurn. Some motion commands use the previous laser power levels (or spindle speeds) - some are locked to laser off (zero rpm). Fire-Framing is intentional but I don’t recall Fire-Jogging as something intended. I’ll ask about that.

I think this is a firmware feature. This is why it’s behaving differently across lasers. It’s a safety feature that definitely makes sense ![]()

I think this is the culprit, as John mentioned. As long as you want to have repetitive movements, you should never touch the laser head at all. Only use the jog buttons.

Apologies Melvin. I should have been more clear on my initial post about manually moving the head to stock center. I meant that I was using the job buttons to manually move it. The only time I touch the laser module and move it by hand is when I set focus. Then I move it back to home and reset my engraver. Going to do some testing today. I have a couple of flasks that I need to engrave, so I will be making an attempt.

I am having a similar problem I am using a Longer Ray5 5W .The issue I been having is when I finish a project it comes out fine. When I load my next project I hit the frame mode to position my material then laser will run to the 400mmY position and I get a position error message and I have shut down and restart my laser and everything is fine until I complete the next project. I am running this laser on an SD card.I been in contact with Longer support. But what is funny is if I run the GCodes that came with the machine for test purposes everything works fine. I can go from one project to the next no problem. A little frustrated.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.