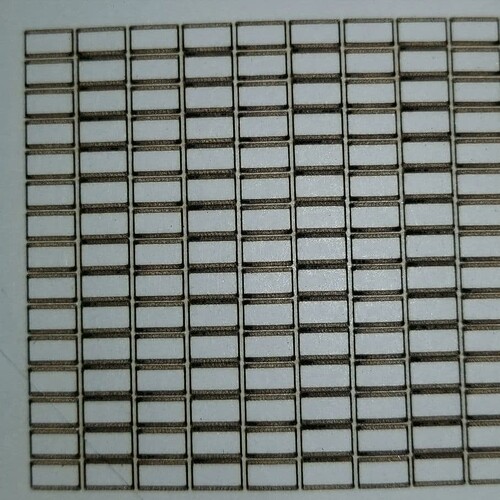

Well theres a issue when making these squares im seeing its the start of the lasers path when making each square where the issue is everytime…

I believe that you are attempting to operate your engraver above the upper speed limits and that you’re looking at acceleration related artifacts.

To test this, cut the power in half and the speed in half and repeat.

Please post back with your results. ![]()

If i cut the speed in half would that not cut right through but still maintaining the thickness therefore not resolving the issue. I guess i could cut the power to half aswell to see the engraving. Ok ill give that a go.

same or similar results the horizontal line is thicker not to mention the pattern of space between the stacks.

I did notice the corners have a better line up on the activation of the laser.

What is this supposed to look like? Can you post the .lbrn file here for review?

What material are you engraving to?

Are you having issues with any other material type or is this your first experience with this specific laser?

Please also list your specific laser model. You may want to also update this in your profile for expediency.

Its just a thickness question for horizontal make a line that is horizontal and then one vertical and u would find the horizontal line is thicker.

Im going to make a file and respond with it then send it here.

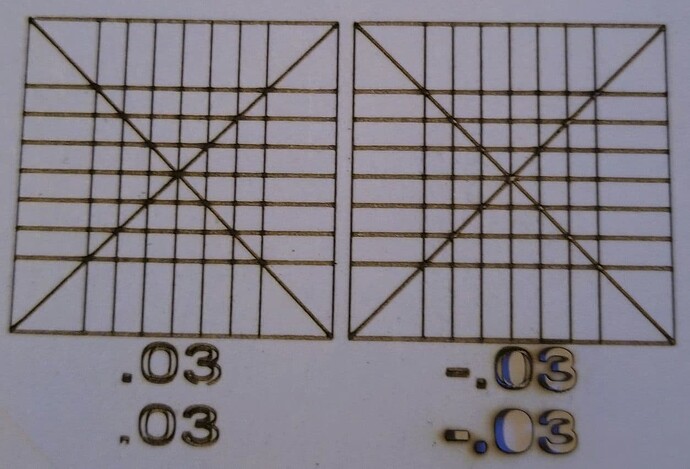

The last photo gives me a better sense of scale. I suspect what you’re seeing is just the asymmetry in the laser focus dot. Looks like your dot is taller than wide. Or it’s possible that your laser is not square to the material. If the laser is aimed at an angle it could be creating or exaggerating the asymmetry.

You can very easily see this if you do an interval test both vertically and horizontally on something like anodized aluminum.

Check for square with a square against the body of the laser module. It may be impractical to directly check for squareness of the laser beam. You could try to measure the distance of a burned dot to projected edge of module to confirm centricity.

If the laser is taller than wide does this make it a defective laser?

No. It’s possible it’s out of spec but this doesn’t necessarily look extreme to me. Try to find a way to measure the horizontal and vertical dot size.

What specific laser module do you have?

According to their website Atomstack claims their M50 laser has a dot size of:

Lightspot Size 0.08*0.15mm

As you can see this is almost a 2x difference vertically which doesn’t look far from what you’re seeing.

Reach out to them for specifics if you’re uncertain of this but I would suggest testing or measuring your dot size to have ready.

ok thanks ill need to measure it and find a way as u say. I will update on what they say here. I will still do some thing like drop the laser a tiny bit and test to compare. I measured it properly as it said in manual but i want to compare anyway.

So the difference isnt too big but It does make a difference cuz i think the vertical burns

deeper.