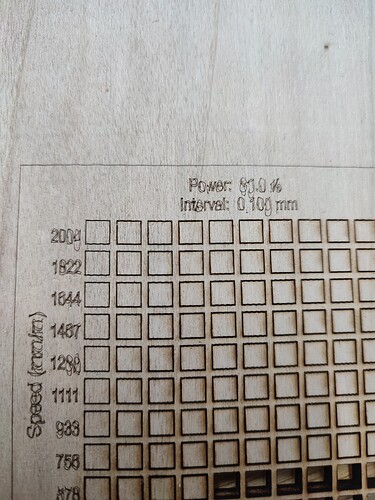

hello, I have been trying to search for this problem for a while now. Today when I started with the machine I did an engraving test with a new wood. since then the lines are wavy. I have tightened the belts but it keeps happening. I don’t know if anyone can think of another alternative. Before this it worked perfectly.

I can see the problem clear as day—those lines are waving all over the place. That ain’t normal, and since you said it was working fine before that test file, something definitely shifted.

You already tightened the belts—that’s good, but not always the full picture.

First thing I’d check? Make damn sure rotary mode didn’t get left on.

Happens all the time—do a test, forget about it, and now your Y-axis thinks it’s running a chuck or roller. Go to Laser Tools > Rotary Setup, and just make sure that’s off. Close LightBurn, reopen it, start fresh.

If that’s not it, next up is those tiny set screws on the pulleys—especially on the stepper motors. Belts can be tight, but if the pulley’s slipping on the shaft, you’ll get that wavy crap every time. Use an Allen key and lock ‘em down hard.

Also, slow down your speed a bit. I see from your test grid you’re running pretty fast. MDF can vibrate like hell at high speeds, especially thin stuff. Drop the speed a bit—maybe cut the engraving speed in half and see if it cleans up.

And clamp that wood down. That second photo’s telling me the material might be warped or lifted a little. If the beam’s out of focus by even a hair, those lines will wobble, especially on fine stuff.

Worst case? Power supply or driver’s acting up, but don’t go there yet. Try the basics first—rotary, pulleys, speed, and hold-down.

I can see variations in the Y axes. You see this because it isn’t straight along the X axes, Y is changing when it shouldn’t. When going in the Y direction, you don’t see the variations since they are in line with the faulty axes. X is working, Y is not.

You can usually see the effect of the loose axes, it’s visible on the opposite axes.

Your photos following the materials test, the issue appears to have moved to the other axes?

Did you maintain the posted photo orientation with the actual X and Y orientation in your machine?

Whatever axes, that I can’t determine, has a mechanical problem.

Is there some reason the outline of the test is thinner than the box outline? Could it be they are just darker?

![]()

the second photo is rotated. Everything happens on the same axis. Some lines are darker because they have more power or passes. I have made a new test only of lines and I have again the same problem I had when I bought the machine, the movement is only on one side. Attached photo. In the lines I have made different speeds and powers, first with a pass and the next line with 2 passes. You can see perfectly which is which.

can you explain me how to do that. I think I don´t know what part you´re saying

@jkwilborn @thesven

I have set the speed to 200 and the left side keeps moving. When I mounted it for the second time it happened to me because I had an old screw, but I have checked the machine well and it seems that they are all well tightened, the belts tightened and I don’t know what else to look for.

If you are very sure that your belts and pulleys are ok, then you can check if there is a lens loose at the end of your laser, it does not have to be the outer one, it depends on the diode type.

But, I also tend to think that you have a “normal” mechanical problem.

To check the small pinion screws, you have to manually turn your axes until you see the small holes with the screws, use a suitable allen key to tighten.

I have checked the belts, the pulleys I don’t know how to check them. I don’t know what the pinion is.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.