That’s an interesting image/file. Your objective escapes me, however. If you want to create an offset around the entire object and use line for the inner portions, you have to break and connect those segments which represent the perimeter.

It’s not particularly difficult to establish a single path in order to have offset work as you describe, but can you indicate/provide which path(s)?

Consider to “bust 'em up” into segments and put each segment on a different layer, for easy reference to describe your objective.

There are a series of shapes that can’t be filled unless they are duplicated and share borders with other shapes.

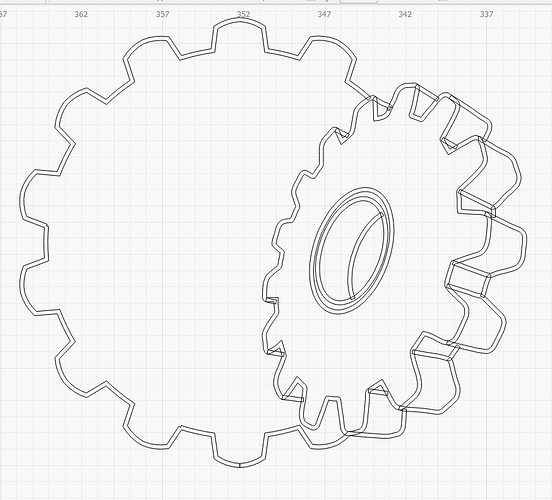

Just as an experiment, I brought your file up. I think it probably started life as a DXF file as there are so many inconsistencies consistent with that format. More than one or two duplicated/overlapped segments and a ton of non-connected segments that appear to be connected, but really are not.

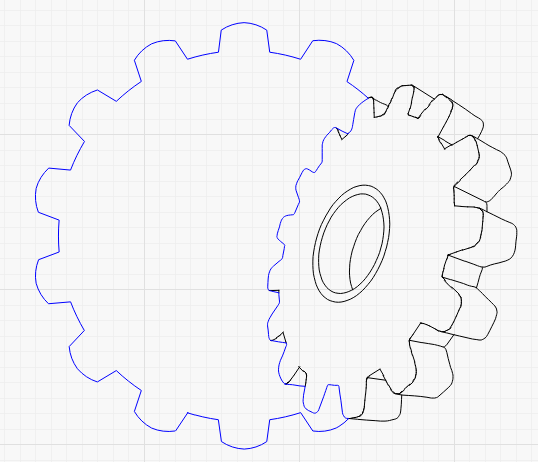

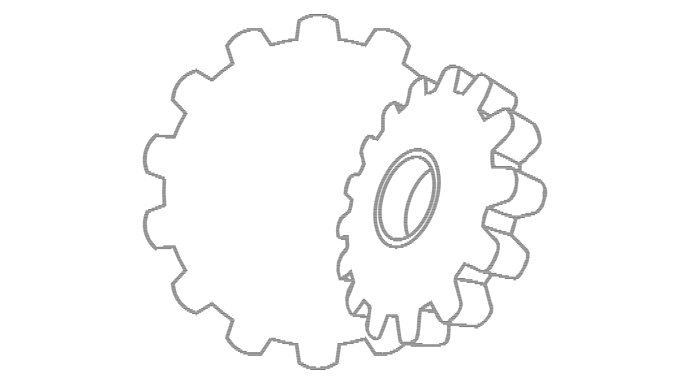

I’m no whiz when it comes to this program, but I was able to make a properly joined/closed shape from the inner gear:

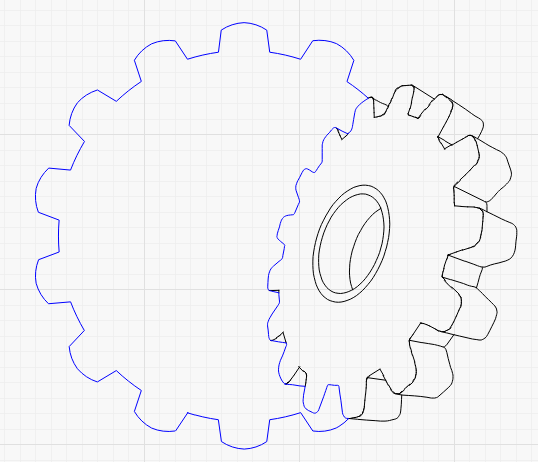

The blue section is now one continuous line, which may not be what you want, but it’s easier to identify this way.

I’ll attach this mod for your viewing pleasure.

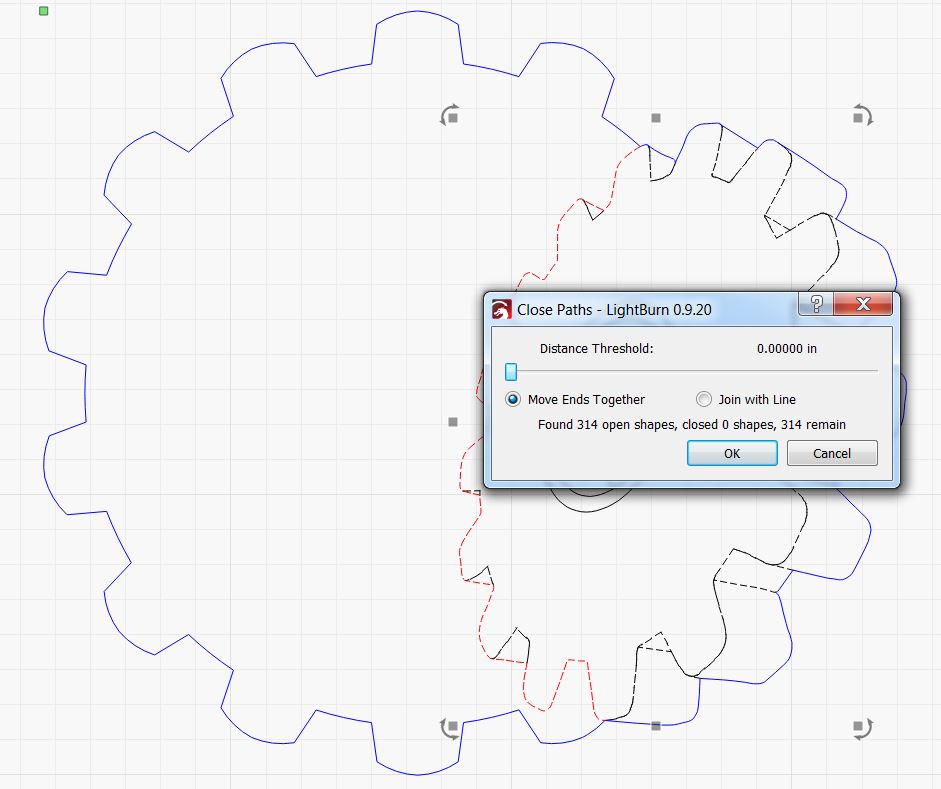

I learned a useful task this time around. The feature “close selected paths with tolerance” presents a dialog box suggesting to close with a line. You start with the “show me” button which selects those ornery segments, then use “close with tolerance” and close with a line. Use the slider to increase the tolerance until the line appears and the open shape count drops. It will then allow you to see exactly where the problem resides.

Oh, yeah, I had to use Arrange, Break Apart to get the DXF pieces to behave. That results in itty-bitty-tiny line segments that have to be “collected” and joined with Alt-J but it’s easier to keep track if you give them a temporary layer and turn off the layers you don’t need.

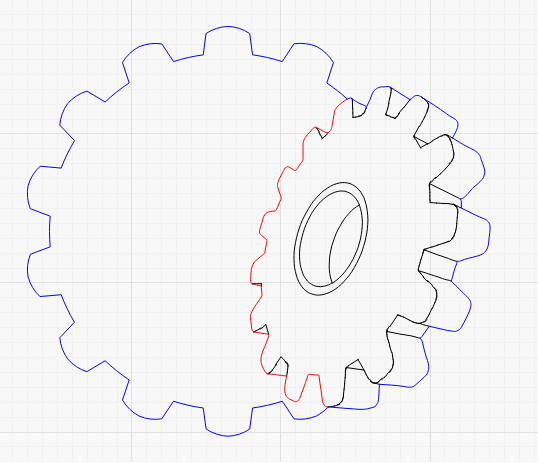

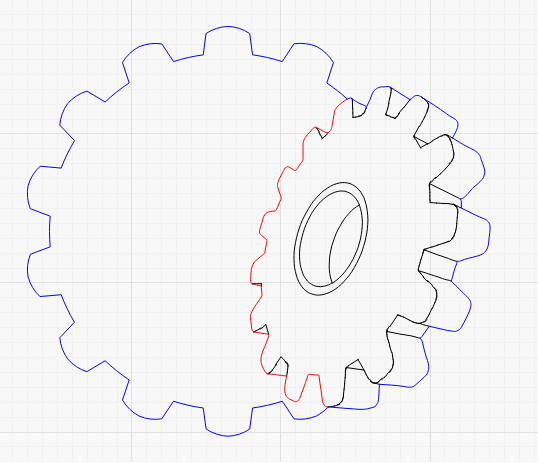

In case you wanted the outside of the entire logo to be closed, I’ve played around with that as well.

The previous collection of joined segments has been dumped on the red layer and the blue layer is once again a continuous/closed shape.

That file is also attached. Please note that my settings may not reflect yours and you should examine and adjust the power and speed as required, if any portion of these files work for you.

partly corrected Logo v2.lbrn (194.1 KB)

partly corrected Logo.lbrn (181.8 KB)