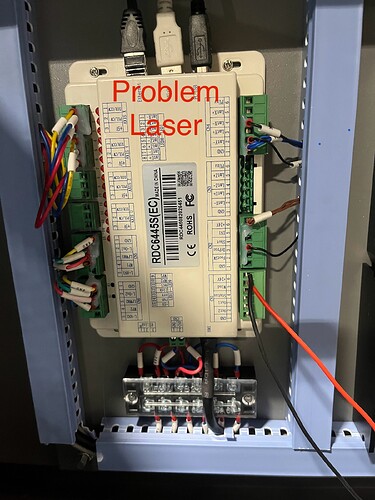

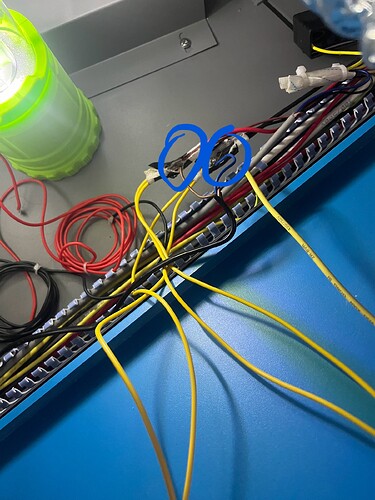

Hi everyone, I installed an upgraded air assist system on my omtech laser but am having trouble getting it to actually blow air. It’s an omtech sh1390 with a RDC6445S controller. I have the exact same setup on a different laser that has a RDC6442G-B controller and it works no problem. On the working laser I noticed it has a VDC wire going to another VDC connection on the motor step drive (circled in yellow) as well as a ground connection to the green light on top of the machine. Is it not working because of these missing connections? I checked the software and air assist is enabled, air is also enabled on all layers. Also the problem laser had air assist built in I removed. I have a picture of how it was wired (circled in blue).

I’m assuming you have a voltmeter?

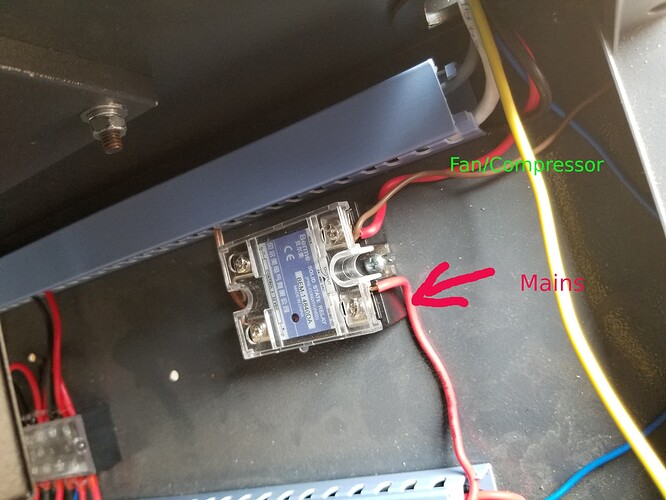

Are you switching the 120/240V mains to the device? If I’m looking at it correctly, it’s a ssr (solid state relay)…?

That’s what I’m using for my ventilation switch. The enable end, is wired to 24V then to the status sink.

The wind signal goes active (low) when it’s in run mode and the layer has the air assist enabled.

I use an external compressor and run through two solenoid valves for low and high pressure

![]()

Yeah I have a voltmeter, and I looked up the relay and I believe it’s an electromagnetic relay. I haven’t touched the mains though so I don’t know if that might be an issue. I also am just using one actuator for high pressure from an air compressor only when the lasers running. Do you think wiring it for status instead of using the wind connection would work?

Most of us run a min/max air pressure system.

On mine, status (run mode) enables the solenoid (left) that opens the air from the compressor to my machine. The right one is closed, so air flows through the restrictor valve to provide low pressure to keep debris off the lens.

When the machine is in run mode and the air assist is enabled on the layer, the wind sink opens the right hand solenoid allowing full pressure to enter the system. It effectively bypasses the restriction valve.

Anytime it runs, I get minimum pressure air for lens protection, when I use air assist on the layer I get full pressure air…

Does this make sense?

You can measure between 24V and the status or wind and you should read 24V… I do on my machine… You can just measure it as it and see if you read 24V. If not, the output has failed or it’s a configuration of the Ruida that’s at fault.

The manual recommends a snub or back emf diode on coil driven loads.

![]()

Yes that makes sense! I’ll have to try some stuff out tomorrow and I’ll let you know! Thank you

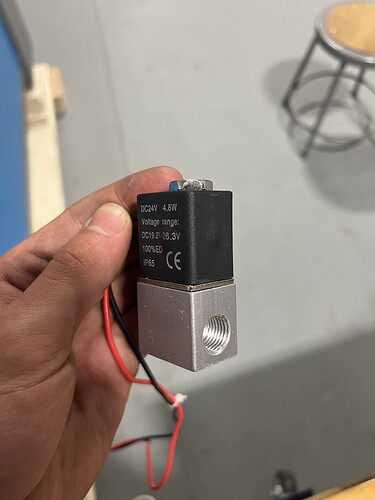

Got it all figured out, I was looking back at all the components and realized this solenoid was pretty messed up. I must’ve not noticed it and just grabbed it. Thank you for your help!

Not sure how old the laser is, but any modifications will void the warranty. Mine burnt wires along the chain tray on the Y axis. A factory problem. Because I added an air solenoid, they would not cover it, nor the fire in the laser the next evening that cost me $700+ to fix. Understand that any modifications (including a sticker on the front…yeah) to the machine is on you.

I don’t think there is anything consistent with Chinese vendor help… Some deny it just because, others are clueless what you’re complaining about as their primary language is Chinese.

![]()

Very true. In my particular case, Atomstack/Ikier, it appears that they use a 3rd party to handle Support. I can guarantee that neither English nor Chinese are their native language. Imagine the confusion and aggravation this causes. I’m resigned to having a $2000 paper weight at this point. It is just not worth arguing my case with a new person each time and going orver the same old same old.