So I know that with lightburn (Galvo) an X axis table is not supported but at the same time when using a rotary you can go outside the confines of the work space to engrave all the way around a mug. So my thought is to use the rotary output to operate the X axis table. I have everything calibrated so that if I tell the rotary to jog 1" it jogs exactly 1" and I am able to jog the entire 24" of stroke that the actuator has available. The issue I am having is that to get it to work I am telling lightburn that it is a roller rotary, but the screw gear on the actuator is geared down so far that I have to set it to a roller diameter of .06289" then when I try to tell it to run something that is say 14" long it will slide the table about 3" start engraving but after about 3" of engraving it slides the table again and continues the job over what it has just done. It keeps doing this until the entire job is done on that small 3" area. So my questions are: Is there a limit to the number of pulses/steps the stepper motor can do in a single job or what is causing the job to only run in a small aprox 3" section? Has anyone else tried this. Will getting a belt driven actuator that is not geared way down solve the issue?

Yes I know that I could use EZCAD and this X axis would be supported but I dont want to, I prefer lightburn. FYI I am wanting to run longer jobs such as gun parts in one job instead of sections at a time and then realigning.

Did you try what I posted to your last post this afternoon?

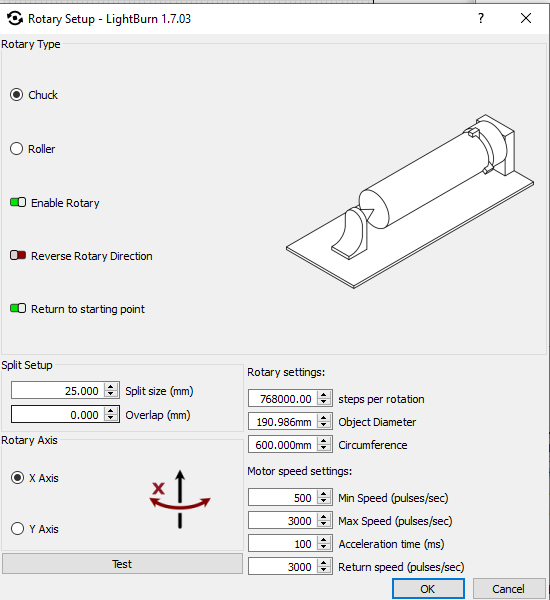

Really curious to see if this works for you. I checked the numbers and LB does take 6 figures in the steps. This is what my setup would be for microsteps per rotation=6400, 5mm pitch screw, 24" travel:

I would have to move too much stuff around to test tonight but similar setting have worked recently. Might have time to try this weekend.

Based on:

DIP on the microstep driver is 6400 you would need to adjust accordingly.

travel is 24" so even number 600mm.

screw is 5mm pitch=6400 steps move 5mm. 768,000 move 600 mm

Sorry just notice I was replying to you on another post that someone had started about trying to get an x-y axis table working. I figure it might be best to continue the conversation here so that if others are looking for single axis table work around they’re search results here on the forum are correct. Will be checking my settings and attempting to adjust as you stated shortly

So I just opened the case of my laser and my driver is set to 12800(duh, I should have known that as that is the value I use for running my standard rotary) I adjusted the dip switches and set to the parameters you gave but when I start a job lightburn seems to get a headache it just sits and gives me the spiny circle and my computer tells me lightburn is not responding. I lowered it one step at a time to 1600 and that brought my steps per rotation to 192000 now it works. I’m wondering if it is lightburn or my computer that cant compute? Thank you so much for all the help Albroswift. If i can bother you a little more, What is your recommendation? Use the screw actuator or switch to the belt actuator that would potentially be a higher gear ratio? If keeping the screw, then do I mount the driver externally and adjust the switches whenever I switch between my rotary and my x-axis table or do I keep another driver with the setting I need and just swap out the driver? Lastly if keeping the screw is there a way to add a second driver to lightburn and just select which one I am using within the program?

So you are probably right, 1,512,000 steps gumming things up. My steps are 6400 but my rotary is 6:1 reduction and my rotary table is 10:1

Knowing what I know now I would get a 20mm pitch ball screw, for this particular prototype. Cut the steps by 4.

Also, no reason to make the circumference 600 unless your workpiece is that long.

Just go slightly over the length is all you need. Save slices and calculations.

Thanks for taking the time to try and post back.

Tried to find a 20mm lead screw, but keep getting 20mm diameter 5mm lead instead.

Know Ive seen them…

I appreciate your help it has helped me learn another aspect of the process that I have not dealt with before. I think for now I will mount the driver externally so I can play with more functions. While I was inside the machine I discovered that the fan on the power supply is not working so I guess it was good that I got in there. Thanks again for helping me!

The belt might be a good idea to try, 1 rotation of a larger pully could reduce the steps substantially.

Still looking for that 20mm pitch ball drive…

Let me know if you find a 20mm ball drive as I feel like a ball drive would be more accurate.

Hi

I have a fiber laser Head mounted on linear table ( one axis 1500 mm ).

Lightburn is not suporting X axis ( yet ). First you have to know exactly what is the steps per rotation for your motor for 1 cm and then every time you change the circumference you will have to change the steps per rotation accordingly.

that the solution that i have found when enabling rotary.

Repeat marking is also functionning but with repeated jobs.

Alibaba has lots. It’s called a high lead, they have 10’s and 20’s Also the US CNC parts manufactures have them but for prototyping I think the price is prohibitive. Also Amazon has a few.

I just set up the belt driven actuator I had ordered and it is running with my Driver set at 12800 It is actually much smoother than the screw driven actuator and is giving me a lot better results. I think for the time being I will leave this setup but if it gives issues down the road I will dig deeper into the screw setup.

Belts are smoother for sure.

Definitely smoother then cheap ball screws. Id really like to try an expensive ball screw sometime.

Thanks for the prototyping and feedback.

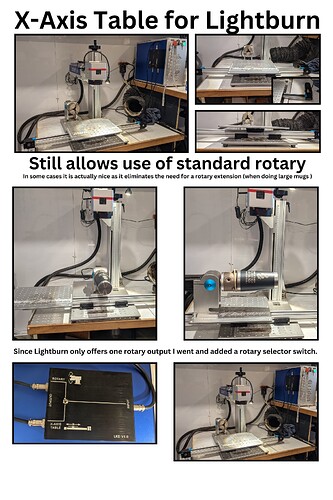

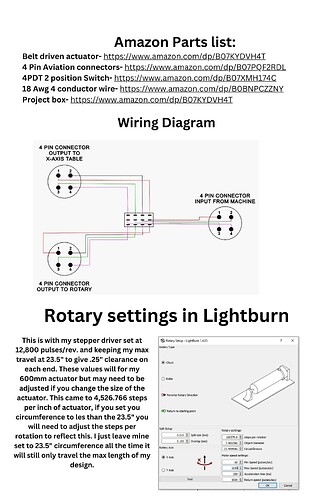

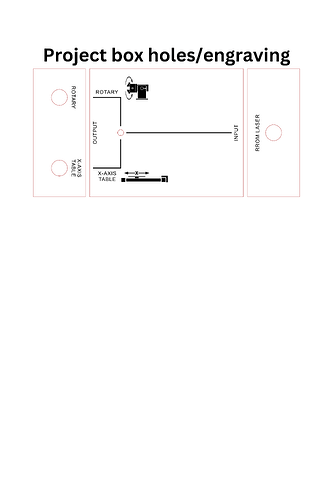

Working X-Axis table for Lightburn. It works great. I ended up also making a 1-in 2-out selector switch box so that I can have both my rotary and my X-Axis table plugged in at all times and then just select which one is used.

Amazon Parts list:

Belt driven actuator- https://www.amazon.com/dp/B07KYDVH4T

4 Pin Aviation connectors- Amazon.com: DGZZI 5Pairs GX16 4Pin Male Female Circular Aviation Connector Plug 16MM Wire Panel Metal Connector : Electronics

4PDT 2 position Switch- Amazon.com: mxuteuk 2pcs MTS-402 12 Terminal 2 Position 4PDT Mini Miniature Toggle Switch Car Dash Dashboard ON/ON 5A 125V 2A 250V : Automotive

18 Awg 4 conductor wire- Firmerst 18 Gauge 30 Feet 4 Conductor Tinned Copper Electrical Wire for Lighting, Speakers, Relays, Controllers: Amazon.com: Tools & Home Improvement

Rotary Selector.dxf (83.4 KB)

A BIG THANKS TO: Albroswift[Al Fernandez]

Without his guidance I would not have this done. I was stumped and his input got me over the hump. Thank You

Power off before switching. Hard on microstep driver to connect/ disconnect from stepper when powered, even when not in motion.

Thanks for posting the partslist!

Good to know, I had no Idea! Thanks again for helping me work thru this project I really appreciate your time and effort.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.