Hi Rick,

I’ve e-mailed some files for you to review:

…laser cutter pauses frequently during the job.

BigBlockCore5 is an example of the pausing issue. Unfortunately I am in quarantine and will not be able to get back to my laser cutter for a few months so I cannot record a video for you. I’ll do my best to describe how my machine would behave after starting this job. It follows the order shown on the preview in lightburn.

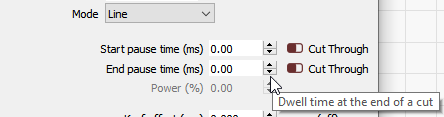

Firstly the cutting head is moved to the location of the first cut. There is then a noticeable pause before the text “3C13” is cut. There is then another pause before the cutting head moves to the next text block. There is then another pause before the text “3C15” is cut. Another pause and then the head moves to the start of the shape outline. Another pause and then the outline is cut. Another pause and then the head moves to the next outline. Another pause and then the next outline is cut. Another pause and the head returns to the home position. When it pauses the duration of the pause seems to be consistent and not related to how far the head has travelled. I’d estimate somewhere round half a second.

The confusing part of this for me is that there are no pauses in the cutting of the lettering. There are multiple lines and moves involved in cutting this text. The layer is cut using “line” mode as I’m using a single width engraving font. Why this is treated differently to the other moves and cuts is not at all clear.

This isn’t causing me a lot of inconvenience at this point, but I’d like to understand what is going on.

…issue I have is with file size in large jobs.

I have already been able to split my image file into separate jobs. I believe the issue I have with the horizontal join being visible is down to the cutting head moving to the home position after the first job is complete and then moving back to that same position to continue. I think there is a tiny error in the repeatability of the head position. Mechanically everything looks good, belts are drum tight. The machine is fairly new so I don’t think there is any issue with wear in the gears. Any misalignment should only be due to hysteresis from backlash in the gears due to the manufacturing tolerances.

I have attached the files I created while working on this. One is the complete picture and the others are the split files. I think the starting point for the second file should be the finishing point of the first, plus the line interval from the layer properties. I’d like to be able to check this in the UD5 file to confirm I’ve split and arranged the image properly.

Is it possible to control the start and finish position? If I could request the cutting head hold its last position at the end of one job and then start from the current position for the next job that might also solve my problem. The only option I can see is “Start From: Controller setting” under the Laser menu. This might be because I am offline?

Regarding the UFile (UD5) format, is the file definition publicly available somewhere? I’d love a copy of your assembler/disassembler if that is possible. I understand that a lot of work goes into developing these kinds of tools, so if the answer is no I will not be offended.