The ending schematic is not what you wired up? It conflicts with his video description…

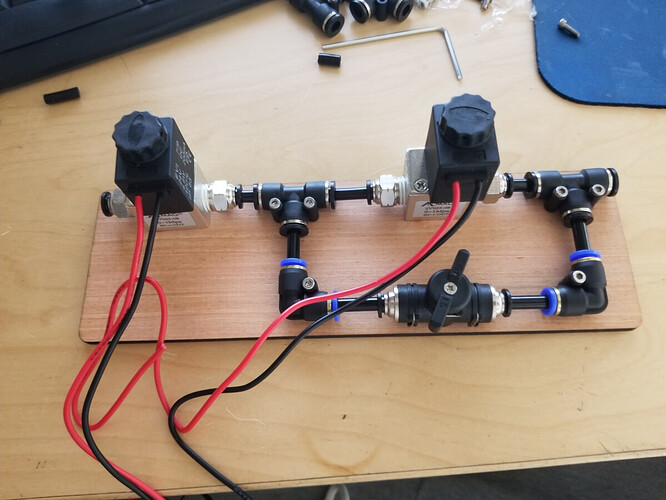

I have what looks like to be the same type of installation… It’s a diy, which you can probably tell, but works pretty much like the description… My solenoid board prototype

Left one (Status) allows high pressure compressor air into the system, through to the restrictor. We know have low pressure air…

When Wind becomes active it picks the right solenoid to bypass the restrictor…

There is nothing I know of in the Ruida to change how this works… Having worked a bit on pneumatic equipment, check that the solenoid can handle the input pressure… Doubt it, but it’s the only thing I can think of…

It sounds like the solenoid isn’t picking when commanded… I don’t know what else could cause an increasing delay like you describe…

Does your solenoids have leds on them? You could watch and see if they opened when the led lit up…?

Make sense?

They may be optical coupled, but there is some kind of hardware between them… I don’t know of any optical isolator that can sink 500mA…

I think he’s got his wires crossed about the color stack lights…

And my short video of status, out1 and out2…

Here’s a more likely schematic…

Ultimate air assist Mk2.pdf.txt (220.5 KB)

![]()