I am installing the Cloud-ray air assist and was wondering what has been done about the needle valve at the nozzle. I am thinking maybe drilling it out a bit bigger but would rather find a thru-fitting if one exists to allow more volume thru the nozzle. Any ideas or help will be appreciated

Thanks

Ray

Generally you only want a small amount of air when the machine is just operating and high pressure when you cut…

How much to do you want to come out?

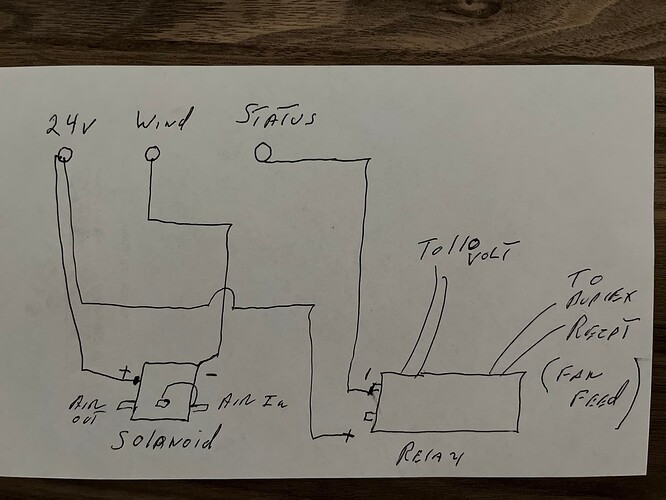

I roughed this out and it’s still in there…

![]()

I understand that and will only have enough air pressure when engraving to keep the smoke off the lens, but when cutting I want as much flow as the pump can put out, that adjustable needle valve seems to be a major restriction

Hi … I have my needle valve set for 5lbs. pressure and 40 lbs. for cutting when I set to cut the Solenoid bypasses the needle valve … just a question … have you plumbed it right?

I think @Boomer has a good question, ‘do you have it plumbed correctly’.

There should not be any ‘valves’ on or near the nozzle with the Ultimate Air Assist.

If you look at my original layout, the restrictor is the ‘valve’ on the board, the outlet on the right goes directly to the head/nozzle.

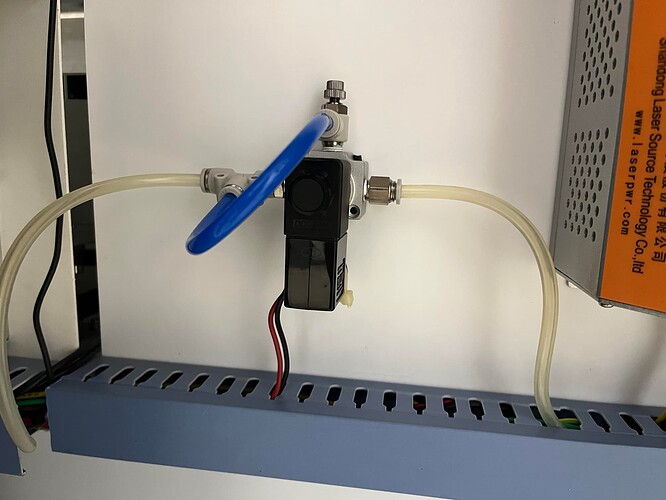

Here is my ‘head’, you can see the only thing there is the air assist hose.

Is this different…than yours?

![]()

I confirmed the correct plumbing of the airlines at the solenoid valve, My fan is not turning on either Thru the relay, DO I need the ground Terminal 1 connected to both wind and status?

right now I have it wired with resistors from the

24volt terminal to positive on both solenoid and relay and wind to air solenoid and Status to fan relay.

I don’t see where the valve is for low pressure… when only ‘status’ is active…

What are you driving with the solenoid?

Fan and air pump?

![]()

Relay is running only the fan, the air pump is on a switched receptacle and the solenoid controls air on/off

Where is the restrictor in your plumbing?

![]()

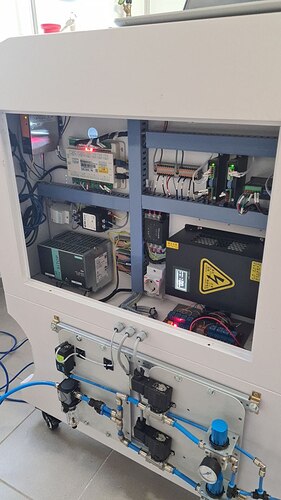

That air pump is on a switched receptacle from the factory for manual on-off. solenoid only controls airflow High and low for cutting/engraving. Relay controls 110-volt receptacle I mounted on the back of laser to turn the fan on and off automatically

I used a value much like yours on my original. It had plenty of air flow at low pressure…

Those valves didn’t work quite right for a while… does yours work right…?

If you need more you’ll have to modify it, but if I recall that valve seat would be the restriction so it may not be able to be modified for more flow.

Good luck…

![]()

Perhaps you could adjust the needle Valve at the nozzle for cutting and the one by the solenoid valve for engraving - that’s how I used mine - I have full control of both settings. The picture on the cloudray website shows the plumbing,.

That is one nice clean looking rig.

Randy