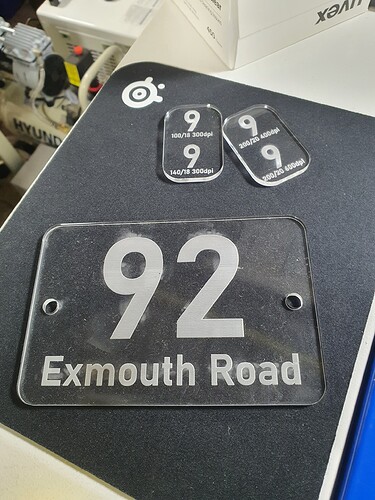

So, I have been ‘playing’ around for a few months now, trying to sort this issue out. I am unhappy with my results when engraving cast clear acrylic from the reverse side.

I wish to make a door number to mount on the wall.

I have tried a lot, and I seem to get one issue or another every time.

Keeping the protective film on - the film itself seems to contaminate the engraving. When I remove the film, I get a fog/halo effect around the engraved text that I can’t remove. I have tried neat washing up liquid but to no effect. I’ve tried tape but ended up with the tape being burnt into the lettering.

I’m using a big Chinese 1390 100 watt laser. If I fire at less than 20%, the tube is not happy. The maximum output has been tested and reads 129 watts. I have a Ruida 6332G control system with a live focus head controlled by RUIDA LFS-ANM-T43-V2 (Though this is switched off)

Most of the engraving has been done with a speed of around 200mm/s and power at 20%; DPI is about 300.- Though over the months, I’ve tried most speeds and power settings.

I use a 63.5mm 20mm diameter lens and 25mm mirrors. The spot size is extremely small and very clean/circular. (See photo below. difficult to photograph)

I have had a perfect result, but that was with air off entirely and no film. But I still get the odd mark, and I need this to be consistent. I am worried about contaminating the lens?

I have two compressors; the smallest is a silent ‘nail bar’ compressor and the air delivered is just right to offer some positive pressure out of the nozzle. I’m at a loss; such a small amount of air can interfere with cast acrylic engraving quality.

Any suggestions as to what I am doing wrong?

VIDEO link at bottom of page - if you are interested to see the laser working.

This is the result I am after the lettering is solid and white - but I must keep air off and film removed. Is this correct?

With the film and air assist on the quality of engraving is very poor.

The Dot size is small - the black dot you see above is the hole made through 4mm ply when the beam is pulsed at 20%.

The above link shows the laser at work on clear acrylic.