Summary:

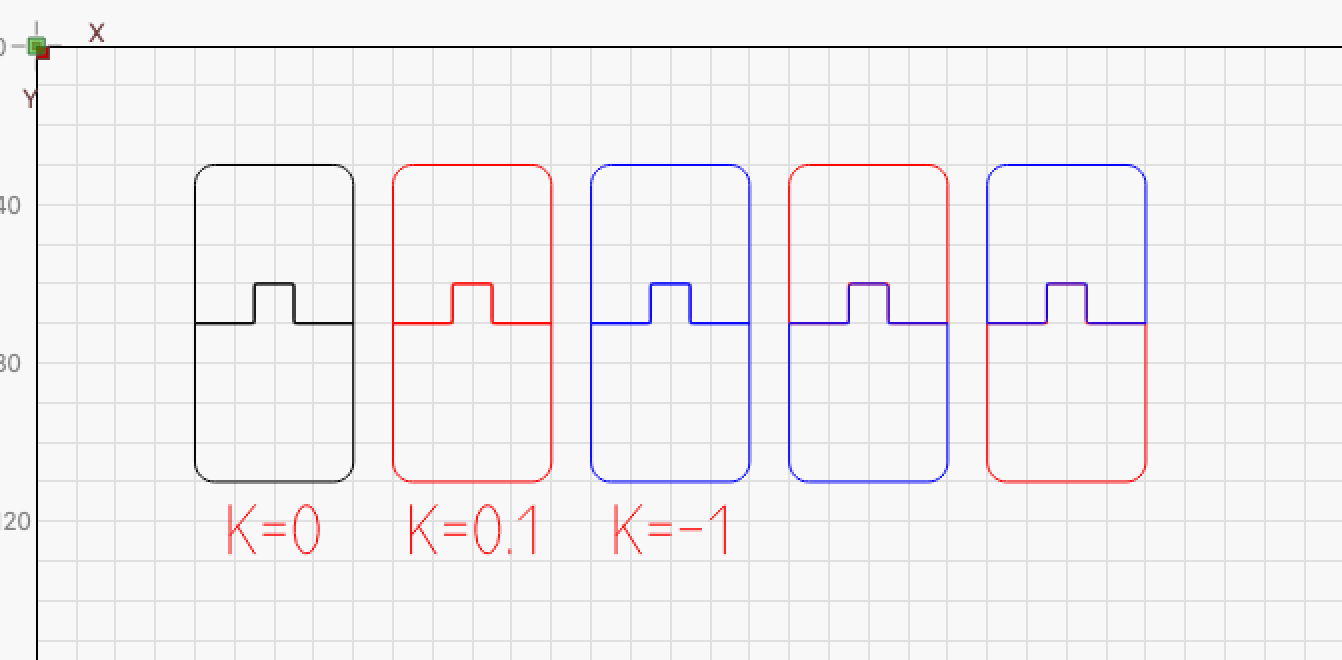

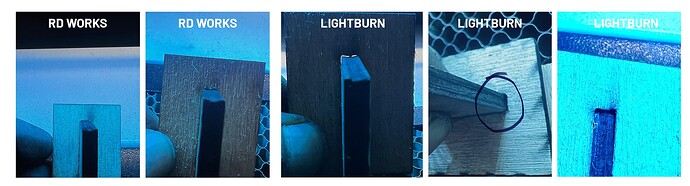

I’m encountering a critical issue where kerf offset is applied in the opposite direction of what is expected.

Setup:

- LightBurn version: 2.0.01

- Controller: Ruida (RDC6445s)

- OS: Windows 11

- File format: .lbrn2

Steps to Reproduce:

- Import Ruida device profile

- Create a slot shape (e.g., 20 mm x 400 mm)

- Apply a +0.2 mm kerf → the slot becomes smaller

- Apply a -0.2 mm kerf → the slot becomes larger

Additional Notes:

- I confirmed this is not due to calibration – axis steps are correct

- The green anchor point appears globally and affects all objects when Ruida is active

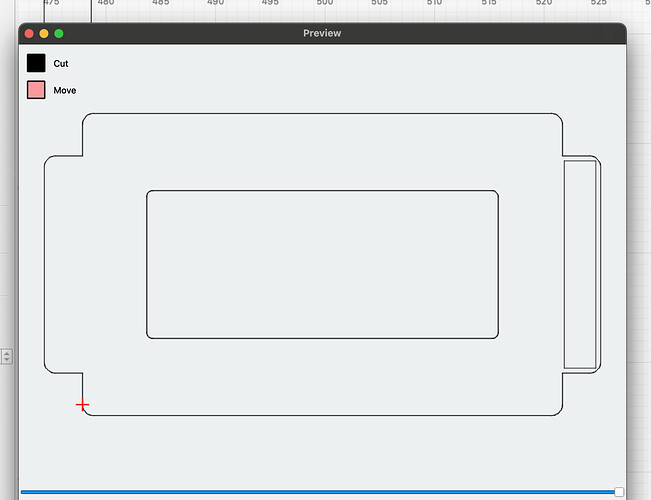

- Kerf Preview is misleading: shows expected behavior, but cut result is inverted

- Measured with caliper: 5 mm deviation on 400 mm slot when kerf is applied

Please advise if this is a known issue or if this is related to recent kerf logic changes in 2.0.01

Thanks!