So an interesting thread here on Lightburn caused me to consider installing a Gas Air Flow Meter on my CO2 laser. For those times when you still want a little positive pressure in the lens and nozzle, to keep out the smoke and debris, but you don’t need the full on air flow that the factory pump provides.

Now I say that, knowing that there are others out there with 50 gallon tanks and multi cylinder compressors that are putting out a bazillion PSI and doing as much cutting with their air pressure as they are doing with their actual laser beam. Ok, perhaps a little exaggeration. But you know who you are.

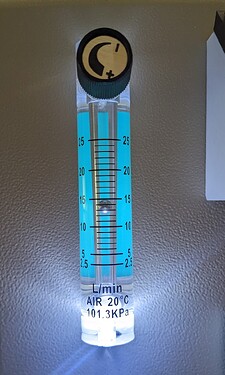

When I bought my 60W laser, it was with the intention of doing more engraving than cutting, so I spared the 150W tube and stayed small. I also don’t need a ton of Air Assault, just a little Air Assist to keep the flames at bay, and the soot to a minimum. Anyway, the included air pump was of the 30 Liter per minute, 16 watt variety and seemed to put out a reasonable puff. Much better than the diaphragm type pump of my old K40 and much, much quieter. After installing the Air Flow meter, I found that the typical 30L/min pump was only seeing about 12-14L/min after travelling through my systems hoses and reaching the nozzle exit (about 17L/min if unrestricted).

So I thought, what if there was another diaphragm pump out there with a little better flow? I found a 25 watt, 54L/min pump on AliExpress and ordered that up. When it got here I was a little disappointed because although it said 25 watts on it, it also said 30L/min, just like my old pump (even though their listing said it would put out 54L/min - so it’s being returned as we speak). But then I stumbled across an Ortur air pump that again claimed 50L/min, so I ordered up one of those. It arrived tonight, and I installed it immediately… it was a bit better, but not the 60% improvement that I was expecting.

Anyway, here are some results…

The original Aqua Blue 30L pump:

Its output:

Video of output (using the highly scientific water wobble test):

The Ortur 50L pump:

Its output:

Video of output (also using the highly scientific water wobble test):

That Ortur pump is built like a tank, and for $104, it’s very quiet, and I may keep it as my main pump and keep the original 30L/min pump as a backup.

I doubt I’ll ever need anything more than this in my 60W laser, but if I ever purchase a 150W cutting beast… then I’ll put that one in the shop and tie it into my shop compressor, since it’s never going to fit in my upstairs spare bedroom where the 60W resides.

Just thought I’d share the info here on the Lightburn Forum. Oh yeah… it was the Geek in me that decided to stick a single LED in the bottom of the Air Meter.

Parts:

Air Meter Link.

Ortur 50L pump link.

Jim