I would like to know what effects using normal drinking water would have to cool my tubes. I have 12 4-head laser machines. In some tubes I see that cutting efficiency has been lost. Could someone explain to me the various reasons? thank you very much I’m new to this

External corrosion isn’t related to the coolant used, unless it’s leaking somewhere.

Your drinking water and mine are very likely different in minerals and other ingredients… So I’d suggest you don’t use drinking water.

The main issue with coolants is that they have a low dielectric constant, meaning they have a high resistance to conduction of electricity.

Some machines have been known to arc from the anode and to the coolant, making anything that comes into contact with the coolant at a high voltage potential.

Not only does OMTech make a coolant, but you can use RV antifreeze in the drinking water from freezing. Just don’t use automotive antifreeze.

Although the RV antifreeze uses a different chemistry, it’s safe for people and animals. Most of these are poisonous to living creatures.

I use the OMTech brand, that I got from Amazon…

![]()

Thank you very much friend, do you think that this corrosion influences the power developed by the tube or the cutting efficiency? Thank you so much

I don’t see a reason not to use demineralized or distilled water in a CO2, it has the electrical properties that @jkwilborn mentions, is cheap and the right thing to protect our machines.

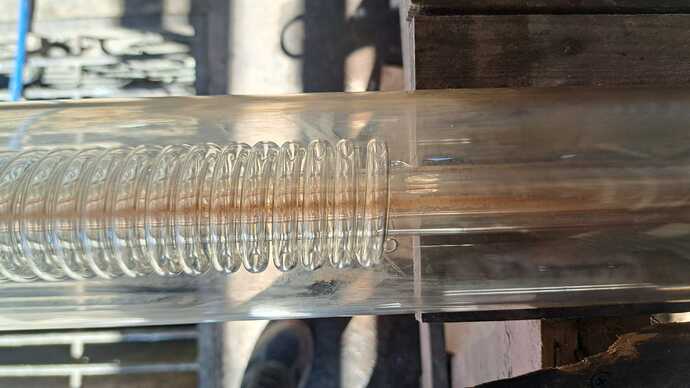

Regarding the effect of the machine, try looking with a mirror in your mirror/lens into the tube itself, it will be interesting and see it in relation to how it looks outside your Tube. In addition to leaks, the corrosion can also be caused by the material you are working with, it is difficult to see in your picture. I have seen machines that work with PVC, they are “eaten up” relatively quickly by the hydrochloric acid that occurs when PVC is burned. This does not only apply to laser machines, I have seen it primarily in plastic molding machines and extruders.

I know I started thread thinking of distilled water, must have gotten sidetracked and went down the antifreeze trail.

Here is a photo of an expensive laser that was used to cut vinyl. What @bernd.dk was advising was material cause.

The actual additive to rv antifreeze is Polypropylene glycol, I believe… I used to run it in mine. I can buy it locally as it’s used to treat milk cows.

![]()

Hey, thanks for your comment friend, note that these machines only cut MDF pieces. Do you think it affects cutting performance?

If the tubes being properly cooled, what you’re doing with it shouldn’t matter.

![]()

My tubes are 170 W, what would be the optimal temperature at which the Chiller should be cooling? I appreciate the time you take to answer my questions.

I set mine to 68 deg F (20 deg C). Mine operates best the cooler it is.

How long is that tube? Seems like lots of power. My chart only goes to 150W, but it’s over 2m in length.

![]()

MDF/HDF “pollutes” quite a lot when it is laser processed, but I personally do not consider it dangerous for myself and my machines, if your extraction works. I use this material a lot and like it.

Have you looked into the tube’s exit opening? I could imagine that the lens (mirror) does not look good.

Keep us informed.

…like Jack, mine also stands at 20 C˚ (18-20 in CW 5000)

Mine sits at 20c but works better colder, i have a small pump that constantly pumps water from my chiller when not in use with a small aquarium heater inside so that it regulates the temperature at all times, ( learnt from a frozen cracked tube when starting out a few yewrs back )

i use pure water, its something our window cleaners use over here in the UK. distilled water removes essentially all minerals through a boiling and condensation process, making it “purer” in terms of contaminant removal, while purified water may still retain some minerals depending on the purification method used, like reverse osmosis, which is often the preferred method for purified water; making it potentially slightly more “mineral-rich” than distilled water

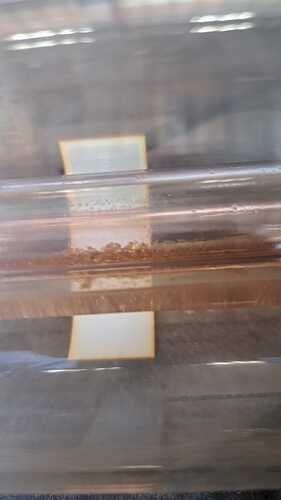

Hello friends, I update you on the status of the tubes, today I removed them and got some surprises. I removed a lot of algae, with a hose. Here they used drinking water as a refrigerant.

I use demineralized water from our local powerheatplant. Here we also have small electric heat generator (12 MW) which has its own water treatment system. Water from this system can be reasonably good compared to distilled water (you can’t use normal water when it needs to be heated above 100 degrees).

And yes, the window cleaner uses it here too. ![]()

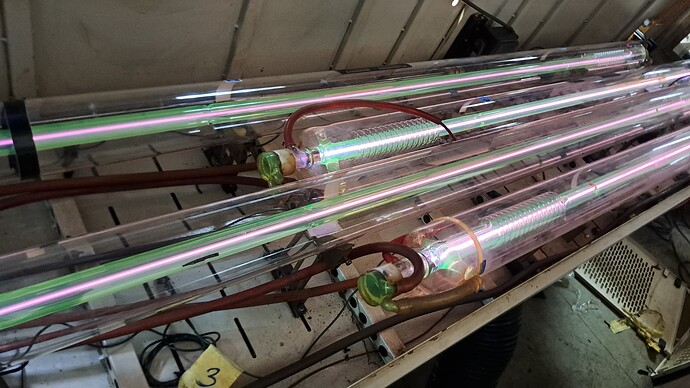

Now I “washed” them and put demineralized water with automotive coolant in them. When the lasers turn on it looks great, like the Cherenkov effect but in green xdxdxd

… What a monster ![]()

I don’t think you really want to do this. There are a variety of chemicals in an automotive coolant.

From a safety standpoint, when there are other materials in the water, it lowers it’s dielectric constant… I’ve seen a number of posts where the anode voltage arced to the coolant, making everything the coolant touches at anode voltage. Most of these on smaller machines.

Also remember automotive antifreeze is poison to all the animals I know.

I’ve been running OMTech version of laser coolant for a couple of years.

Have fun

![]()

I only use RV Antifreeze in all 3 of my lasers for over 8 years and never a problem. I also suggest you change it every 2 years, Charlie

Drinking water varies widely across the US, so if you aren’t going to switch to OMTECH coolant at least switch to distilled water, it will have minimal extra minerals in it like calcium, magnesium, iron, etc. and then add the RV antifreeze if you are subject to cooler temps in your area. Your corroded tube end may be due to either very high humidity or a leak, check for both.