I am starting my first project and have assembled my new Vevor 3018 with a 5W laser, managed to sort out some calibration and settings and more or less understand what most things do.

My first project is to engrave some designs on white acrylic, painted black, that will allow the white to show through.

I am a little confused as to the optimal settings for speed and power as I try to configure all the various $fields.

Does anyone have any good suggestions for a starting point for acrylic to get a gentle engrave and also a cut for example for a hole through 3mm acrylic?

If you do some checking, you may find that a diode laser will not perform well the tasks you require. The black paint may indeed burn off, as it’s black paint, but the white acrylic underneath will scoff at your efforts. Cutting a hole in the acrylic will require a mechanical method such as a drill, as the diode laser will not remove material in the required manner. If you go the drill method, use caution if the drill bits are not plastic-specific. Either find bits for plastic drilling or, as I’ve read elsewhere, run the bit in reverse. Expect cracking or damage if ordinary bits are used in an ordinary manner.

As @fred_dot_u rightly points out, Acrylic and diode lasers don’t work well together. However, since your system is a 3018 core, do you also have CNC capability? If so, CNC and Acrylic were made for each other, including engraving. V, Tapered Ball Nose, and O-flute bits are your best friends.

Definitely go that path rather than laser. Use the laser to engrave things that like to get burnt by 450nm light.

if it’s just for an ink removal so that the white of the acrylic appears, the 5W laser will do it with ease, as it does with black ink on any surface…but it sure won’t cut the acrylic, only diode lasers anymore powerful (40W or more) can do it and only with black acrylic.

The best solution to make holes in this case is, as said, using drills at a low speed so there is no danger of cracking.

Thanks for all the replies. I have a lot to learn about this new world and that was part of the point of my challenge! I initially got this small, relatively cheap setup to try and learn as much as I can and then work out as I go what to upgrade. Its quite a fascinating technology and a great supplement to my 3d printer. Right now the leaning curve is pretty steep, but I always really enjoy that.

@TomWS - yes its a 3018 setup so I have CNC and a small collection of bits with the CNC head, so thats definitely an option I will try. It will be interesting to see how clean and accurate I can get the engravings with CNC. I think I was initially drawn to laser for this as it seems to me a much “cleaner” way to get very accurate and tidy engravings.

Excuse my ignorance on the whole subject but what actually is a 5w 405nm laser most useful for?

What would be a sensible upgrade for accurately working with acrylic as far a a laser is concerned?

is useful for engrave/cut plywood of about 3mm, to engrave slates, with a little pre-prod to engrave tiles

but there is no way to cut acrylic with a diode, for that you need a CO2

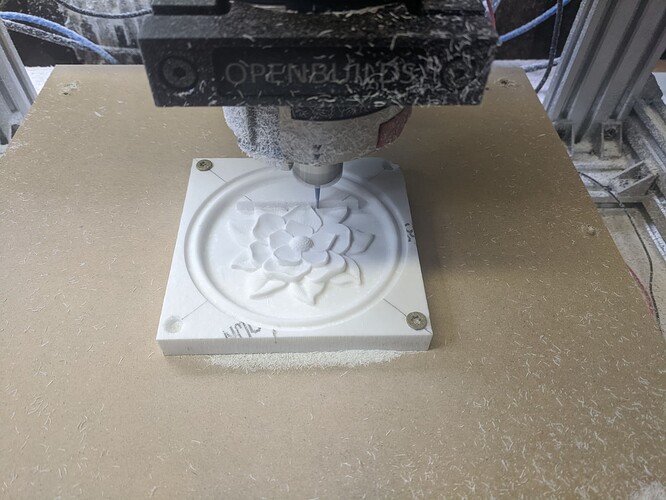

With a CNC router you can easily do something like this:

Note that this photo is not my engraving. I did do this (and it actually came out finer) but I can’t find a photo of the one I did. This was done with a diamond drag bit. Very easy to do.

With your CNC carver you should be able to do this:

Note this is being done on a different machine than yours, but you should be able to do this on a 3018 system. This is white corian with a 1/2mm radius Tapered Ball Nose bit.

As @killrob mentions, diode laser wavelength goes right through acrylic. Some have said they can engrave black acrylic and maybe that’s true, but it’s sort of niche application IMO. You can engrave quite a few materials with your laser with good resolution, but if you want to cut anything serious (like 3mm plywood) I would recommend getting NEJE A40640 40W module. You may need more power supply (it requires 12V 4Amp on it’s own), but they’re inexpensive. With this module and air assist you’ll be able to do nicely detailed wood cutting.

@TomWS Thanks very much for this. I have managed to get some really nice detailed engraved results with the laser on some laminated MDF, but it was more for testing and learning. So i think i see some of its uses and limits now.

I am now going to experiment with the CNC. The bits I have appear to be v-bit type flutes 30 degree, 0.1mm head, if that makes sense.

I am trying to learn UGS as the control interface and see how it goes.

Yeah, the typical crappy bits they provide with these systems. I recommend you get a proper set of engraving bits. FoxAlien has a pretty good collection of four bits that include 60 and 90 degree vee-bit, 3mm end mill and 3mm ball nose. The only things I’d add to that is a 0.5mm tapered ball nose. SpeTool has a good one with an 1/8" shank. Also get an 1/8" O-flute end mill. That is the proper one to use for plastics.

Excellent. thanks. Yes not really a surprise that it shipped with no-name fairly useless non descript bits! Usually that just causes more frustration and pain in the process, so i will have to upgrade these asap.

Now i am just trying to work out how to get all the dxf files i already had in autofusion into some working gcode and then into UGS.

What a laser is good for is really based on the frequency of the emf. Acrylic is opaque to the co2 wavelength but passes the LED wavelength.

Only with something opaque (absorbs the energy) will the laser have much of a chance to do damage.

I have one of those CNC3018 I use mostly for PCBs. I’ve got another one ordered to be here next week. One has a 500watt motor on it currently. Had a 30 watt Neje mounted on it for a while.

Everything you learn will help you if you decide to move on to bigger machines.

If you have a 3d printer and your 3018 isn’t equipped with limit switches you can 3d print them. I did on mine.

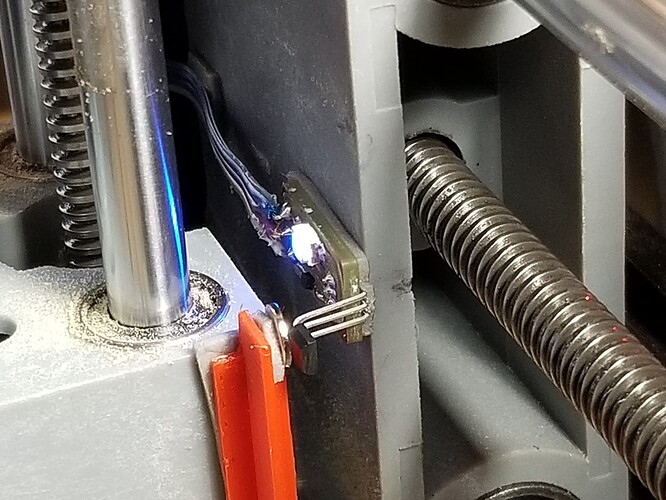

Here is my Z axis limit. 3018 for the pcb and the 3d printed magnet mount. This is Z max.

Same sensor for upper/lower limit or Z min.

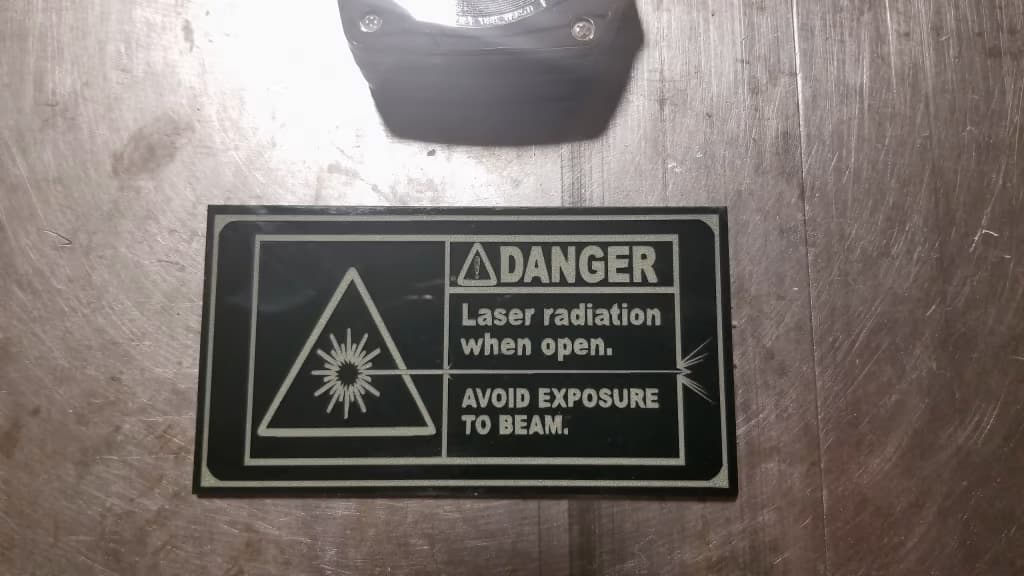

My co2 has a 3d printed mount for my flow meter and a lid cut out with the laser…

Good luck

Many good tips here. The learning curve will continue for a long time for me!Following TomWS advice, I gave the CNC a bit of a try on some acrylic and some crappy bits just to learn a bit about the software and settings. I managed to convert some DXF files using DXF2gcode, and it works pretty well. Then into UGS and even with the crappy cheap chinese bits that came with my 3018, the results were surprisingly acceptable.

The laser worked really well for etching/engraving on the wood and laminated mdf, and the cnc was easy enough on the plastics, so I am starting to get an idea of the possibilities and uses of my very basic kit. I am certainly going to be able to use both for my projects. Once i improve the workflow, things will be a lot more logical. Thanks for all the really good advice on here.

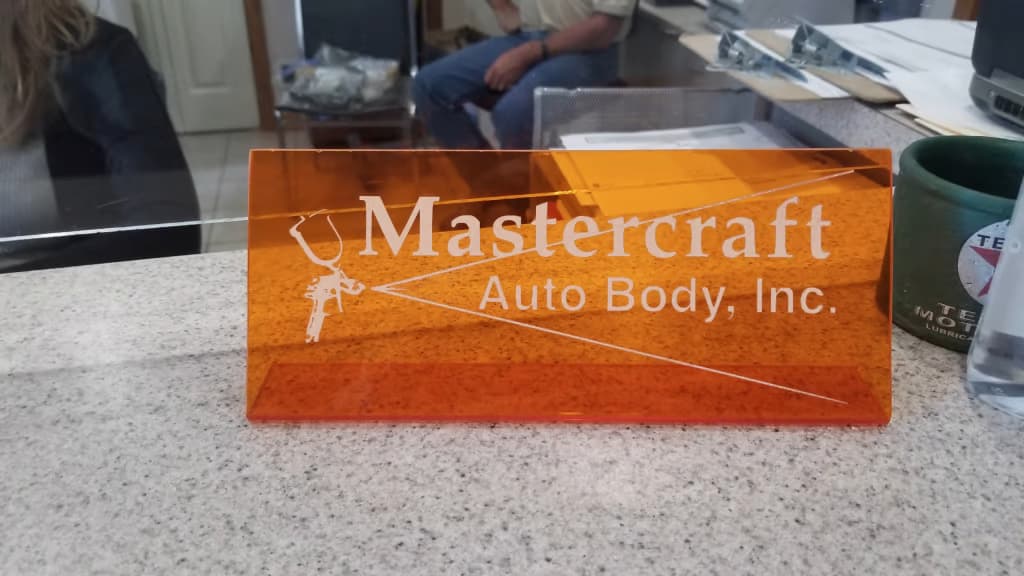

I’ve had some good results on colored plexiglass (acrylic). I’ve done engravings on orange and green plexiglass. I don’t think I could cut it though. Oddly, it engraves a very nice white color. I tried on clear polycarbonate and it does work. But it burns/chars the clear polycarbonate.

All of this was done straight up with no tricks of the trade to get the results.

@LeoG Thats pretty much exactly what I was hoping to achieve with my laser Leo! what sort of settings are u using? Especially the last on on the clear acrylic. I couldnt get any kind of mark on clear stuff as i suspect the light just went right through. However on grey laminate it is very sharp.

@anon88048707 - thanks for the tip about the eyewear! The “gift” I receieved from the manufacturer is indeed green! As i pilot by profession I really dont nee to be ruining my eyes! That is now my very next upgrade!

Well on my main computer it says the clear polycarbonate is either 80% x 800mm/m or 100% by the same speed.

But I know I did a lot of playing around on my computer hooked up to the laser. If I remember I’ll check for you. I never tried it on clear plexi.

I like your homebrew 3D printed limit switch. I’ve encountered that sort of thing mostly in Ham Radio, with fellows building something custom when everyone says it’s not available.

73’s de KA7CMF

![]()

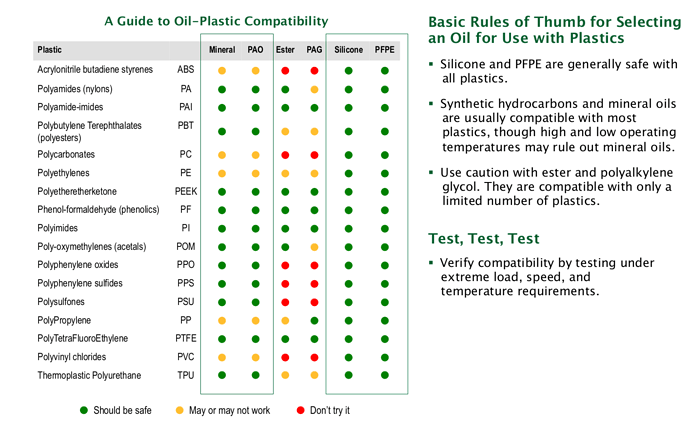

I have done quite a lot with acrylic plexi. I’ve had very good luck drilling with run of the mill HS steel drill bits using silicone lube spray. Cuts nicely without melting or cracking.

Sounds great. I think silicone is one of the suggested lubricants.

Here’s a page out of one of my docs on that subject.

If I’m working with acrylic, I usually ‘lase’ the holes then tap them. It seems to cut much better at a lower spindle speed if I do need to drill it.

This is a nice guide to drilling acrylic…

Good luck…