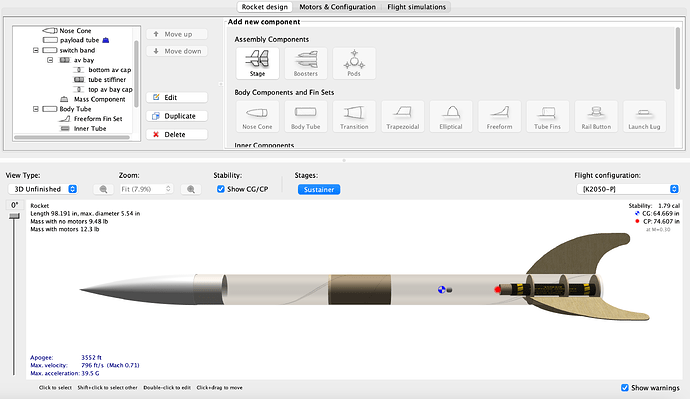

I have been building model rocket kits from Estes when I was in middle school and have since then gotten into high-power rockets and gone on to get my L1 and L2 HPR certifications and am working on my L3.

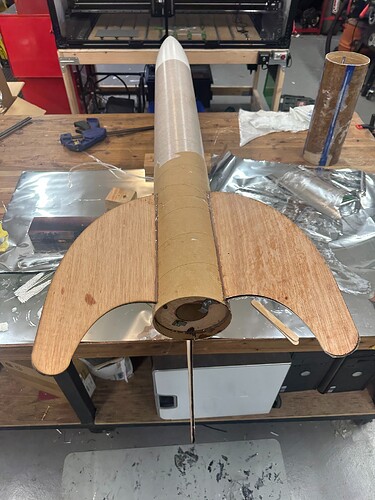

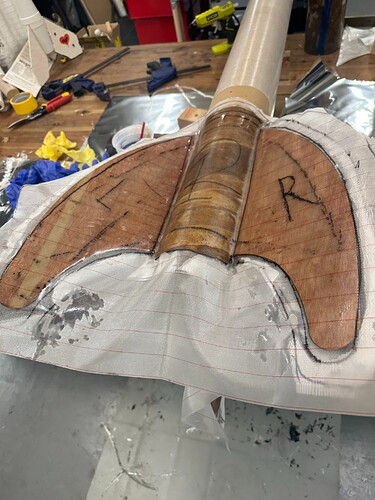

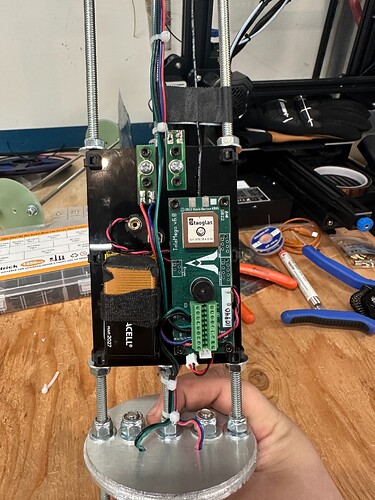

Almost every part of a model rocket whether it’s a Low, Mid or High power from cutting the centering rings and fins or the fin slots in the body tube to cutting out parachutes from plastic or nylon sheets or the paper paters to cutting out fiberglass sheet for the some of the bigger rockets. A large portion of the big rockets that I have worked on are primarily made with Plywood cardboard and plastic sheets. Even Getting into the larger Fiberglass and Carbon fiber Rockets that I work on with my university team we still use LightBurn to to cut out our avionics trays and jigs to align fins.