i am very happy with my first projects using this software for cutting small (and less small) parts to make functional small aeroplanes

so far i have not found any cad programs that offer functions that my very basic requirements need, affordable, and with a less steep learning curve

and thus, lightburn has stepped up quite nicely

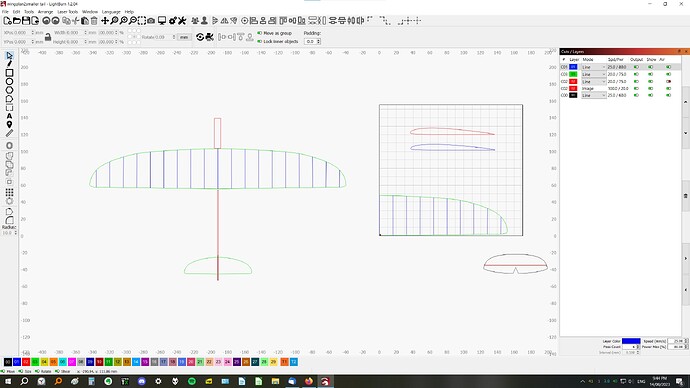

what i need to do though is redefine the work area to create rather simple plans for full working size of the models, and that would be great to do by opening into a newly defined work area

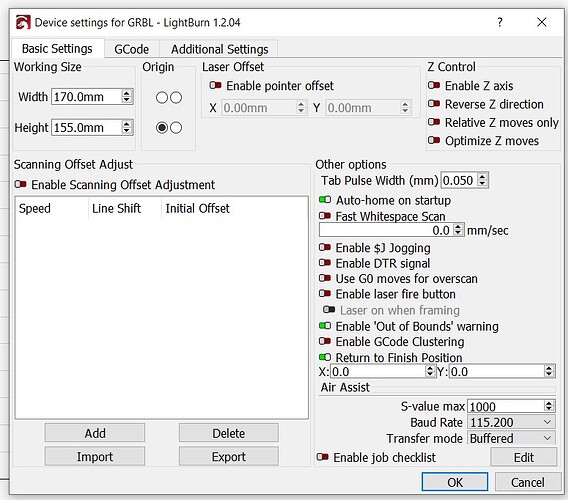

currently i’m using a neje master 2s, and with upgraded laser the available working area is a generous 170x155mm, perfectly big enough to do ribs in small batches

but for design, i reckon 1000x300mm would be the shiz, especially if the grid can be in 1mm increments with more defined lines at 10mm and maybe 50mm for ease of use

so, is there a way to define this design table, and if so, how do i access it without overwriting my current tiny but practical cutting table - they have 2 necessary but independent uses, and it would make my enjoyment of this program even greater

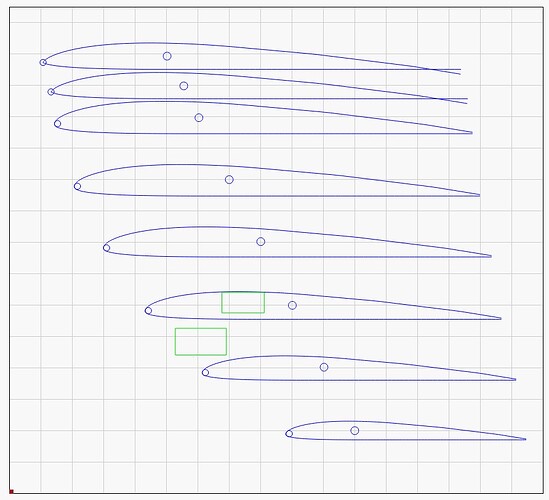

as a f’rinstance, here’s the ribs for a radio controlled discus launch glider (right size for burning)

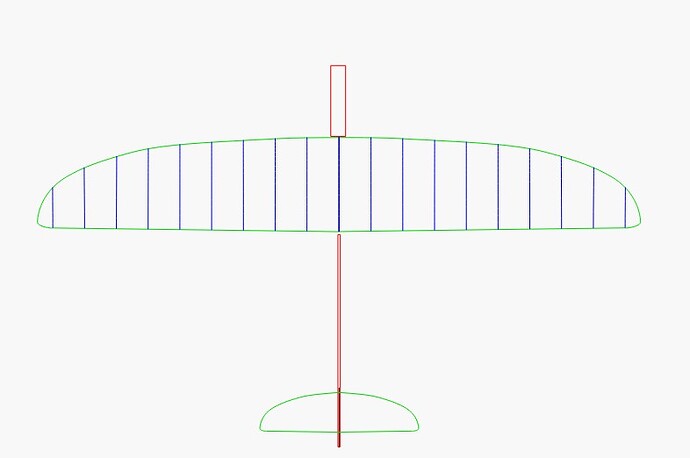

and here’s a wing plan

i had to scale the plan to figure chord lengths, but a 1:1 desk space to draw it would be great - the skills i have with lightburn can be used to simplify the rest of the workflow

thanks for instructions - it would be great to open a “recent project” template and get stuck in, but i want this possibility to not corrupt or lose the burning template for small things - essentially it would be like having 2 machines using the same interface, interchangeably

and i’d be even happier than i am already ![]()