Have been playing with the slots and tabs.

You probably already know this but…

two lines not connected. Node on each end of disconnected line then click on “Dock”. It will connect exactly.

Tried a file that is quite complicated with the slots and tabs, just not worth it. The file had so many lines too short etc. I fixed them rather easily and arrived at a percentage of original file to make it work with material thickness I am using for this project. Doing that made my numbers within .01 of a mm. I think I can live with that.

Can you show a clip of this drawing or preferably the entire lbrn2 file with the problems you describe? It could be that together we get the problems and possible solutions found.

I don’t understand what you mean by that.

Bernd

I have gone through the files I am using now and cleaned them up, connected, disconnected etc.

I accessed an original file for instance: Selected all and noted the dimensions for width and height for material with 4mm thickness.

Then divided my material thickness which is 3.5mm by 4mm to get 0.875 or rounding it off I got 88%.

Multiplied the original width and height by 88% giving me dimensions for each and every drawing in the file that was on LightBurn at the time. Slots, tabs, everything for the file dimensions I want.

3.5mm drawer unit #1.lbrn2 (67.8 KB)

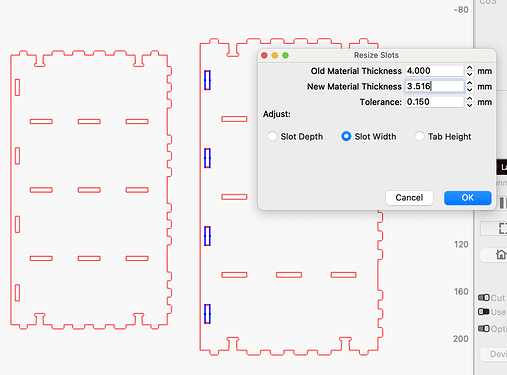

The vertical slots are 3.516mm in width which is the thickness of my material. The horizontal slots are 3.608mm which gives me a little wiggle room for dividers in the drawers depicted.

![Screen Shot 2022-12-30 at 3.32.32 PM|444x500]

(upload://wfRXUn77OJBzHaznTiQKErOJbNZ.png)

I have either explained this better or made it more confusing.

Happy New Year!!!

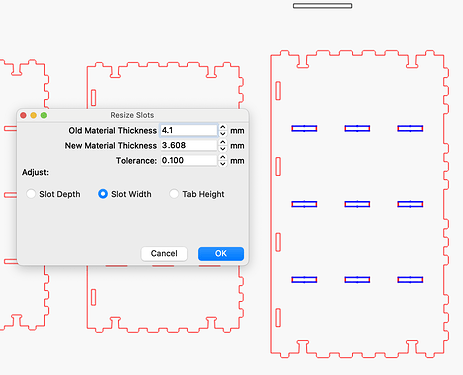

Do you only want to customize slots and don’t care about the size of the item itself (total measure of your overall product)? Then a downscaling in LightBurn with 12.1% for 4 mm of original thickness will be enough (87.90% must be entered). But here you get everything scaled down that is marked, the horizontal slots must be individually calculated and scaled.

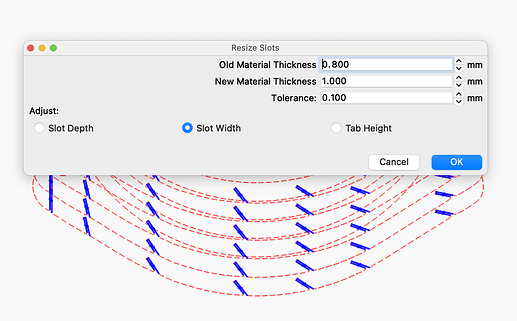

Or you use the new “Resize Slots” tool.

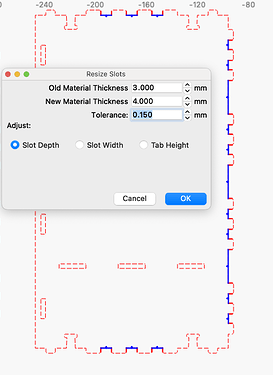

The new tool in LightBurn does a great job of reshaping your horizontal and vertical slots. But at the outer edges, the tool finds its limitations. When I use it for easy connections/slots it’s fine but not quite in your example. As you say, there is a lot of post-work afterwards. However, I think I will be able to use it anyway and save time even if there is post-work.

(in my example I scaled your entire element back to 4mm and used “Resizer” to adjust the slots to 3…mm)

I forgot to mention this is a set of drawers inside a cabinet so to speak for myself. Don’t do that very often. So by changing the entire unit with the percentage the cabinet overall is a little smaller but it doesn’t matter.

I did use the resizer for those vertical slots, it wouldn’t work on the horizontal for one reason or another.

I have gotten rather handy using the nodes.

I want to do some vehicles and they get really tricky because there are hundreds of slots and tabs etc. and the drawing done by the editors leaves a lot to be desired in most instances. Normally I stay away from changes in material thickness if I can. Distributors are running out of stock. I found some beautiful maple veneered mdf, it was the 3.516mm. I ordered a good stock from another supplier that is supposed to be 3.0mm. Should be here next week. Most of these files are written in a multitude of stock thickness making it a lot easier to do the work on my end. We will always have the need for extending or shortening lines, round corners, and square corners. Many are not color coded correctly for what needs to be done so all of that has to be checked and usually changed making the use of at least 50% of the files available too time consuming to bother with.

I certainly appreciate your help.

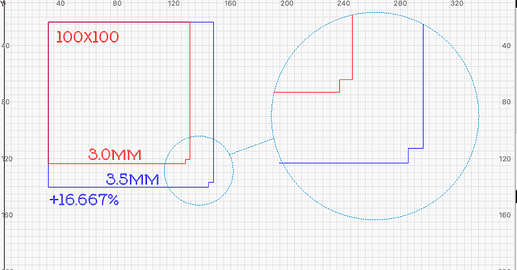

I am the lazy type when only a few parts need to be scaled and overall measurements are not a problem. But of course it has its price. From 3mm to 3.5mm it is 16.67%. Losing over 16% on some expensive material is of course not a solution for mass production, here a redesign is the right solution.

With my lamp designs I am so lucky, here the “Resizer” tool finds all the slots that need to be changed and I have significantly less work to complete the work.

Changing a few slots manually is no big deal and I don’t mind doing that. I make some cell phone stands and am going to present them to a large company we used to do business with.

I know how much my laser cuts in width so I adjust the slots accordingly. Unfortunately since we retired a couple years ago I prefer to work on designs and finalize them in lieu of actually manufacturing in any kind of volume. lol

I am ruthless when it comes to using the entire surface on a piece of material.

Have a great day!