Hi.

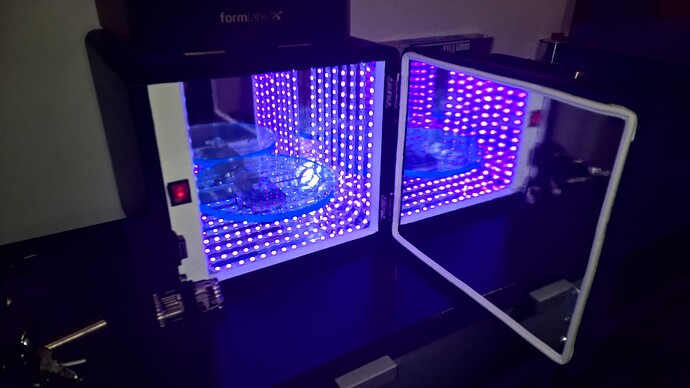

That’s one great looking curing chamber  .

.

A repurposed wine cabinet?

A few years back I was going to repurpose the face tanner unit from an old solarium bed and put it inside an ATA case, but since couldn’t get the first gen. Uniz Slash I bought from a backer as NIB working, I didn’t build the UV curing chamber either  .

.

Since light frequency spectrometers and narrow band detectors are rather expensive and hard to find, there’s a repairpersons trick that is (or at least was before RF TV/video/audio appliance remotes) used extensively when troubleshooting IR remotes.

Haven’t tried with UV, but a cheap digital camera that has no filters will detect pretty far in the IR range.

The better the camera, the better the filters, the poorer the results outside visible range, obviously.

May as well be the optical properties of Your acrylic turntable, but from the pic it does seem that the turntable indeed blocks at least some of the UV.

A straight pic where the turntable blocks some of the leds will remove the optical properties messing up the diagnose.

Unfortunately, unless some more advanced graphic design or photo manipulation software can perform the spectrum analysis from a digital pic, there’s no telling what frequencies/wavelengths are blocked and which pass through.

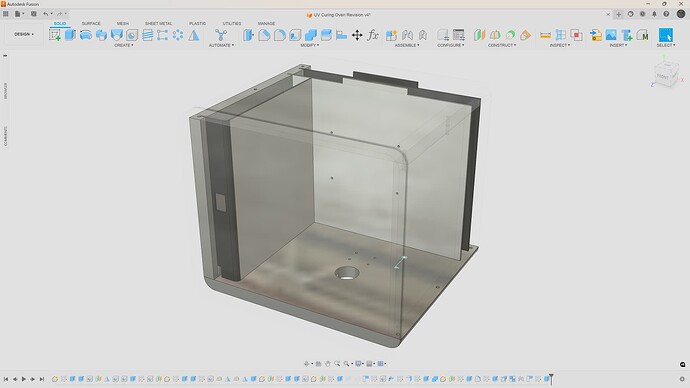

I was also thinking about a turntable, but mine was going to be a glass one.

Or a mirror  .

.

I worked in the trade briefly, so I would’ve cut it myself.

Since most of the glass used today for windows have all sorts of coatings and additives to manipulate the amount of UV passing in either direction, not everything can be used/repurposed for a curing chamber turntable.

Luckily, there’s a trick for finding out whether there’s a UV block coating or not as well  .

.

Hold a lit match or a lighter close to the surface of the glass, and if both the flame reflections are of the same colour, it’s unlikely that there’s a coating.

Some led lamps/torches work for that trick as well, some don’t.

Generally, incandescent light sources won’t work for that either.

Regards,

Sam

![]()

![]()

![]()