I recently built a Cantilever laser engraver. After a couple of comments from Mark at openbuilds about making it run vertical & adding a turntable, I was able to do both. I was trying to use the Z-axis for the rotary axis & initial testing worked in the rotary setup dialog, but could not get it to work when running a test burn. I enabled the Z-axis in the Device settings. Is there another setting I need to change? I was able to get it to work when switching it to the Y-axis. Also, it would be nice to have a feature of using either the X-axis or the Y-axis for the movements along the cylinder in rotary mode. I have to switch the cables on the controller board to get this to work. The cantilevered arm is normally my Y-axis.

I am using an Eleksmaker Mana 3 controller.

Files for this design are here: Horizontal Cantilever or Vertical Diode Laser Engraver by GeoDave - Thingiverse

Here is a short video of the first burn test in vertical configuration with turntable.

Cantilever Laser in Vertical Configuration test burn with turntable - YouTube

Using the Y axis for the scanning axis in rotary mode would be very rare, and would complicate the UI / configuration code considerably, so it’s not something we’re likely to add I’m afraid.

Using the Z axis for the rotary moves should work, but I honestly can’t say if that’s ever been tested. I know people have used Y and A, but I’m not aware of anyone using the Z. You would likely want to leave Z moves disabled for this, since the code generator might actually try to output two Z moves - one for the rotary and one for the ‘real’ Z axis.

I am able to get it to work well using the Z-axis. I initially set:

$102=200.000 ;Z-axis steps per millimeter

& 32 for the mm per rotation in LightBurn.

I got one full rotation, but rotational speed difference was considerable faster than the scanning axis. After doing a video of a dry run of a 100mm square, the speed came out to be 7.296x faster for rotation axis. So I recalculated the steps per mm based on that number, 200/7.296 = 27.412

Since I am using DRV8825 (200*32=6400) 6400/27.412 = 233.47mm.

I did a trial an error from this point adjusting only mm per rotation in LightBurn rotary setup, starting with 233 for that number. My final numbers give me 1 full rotation with rotary setup & speed between scanning axis & rotating axis is the same:

$102=27

243 mm per rotation.

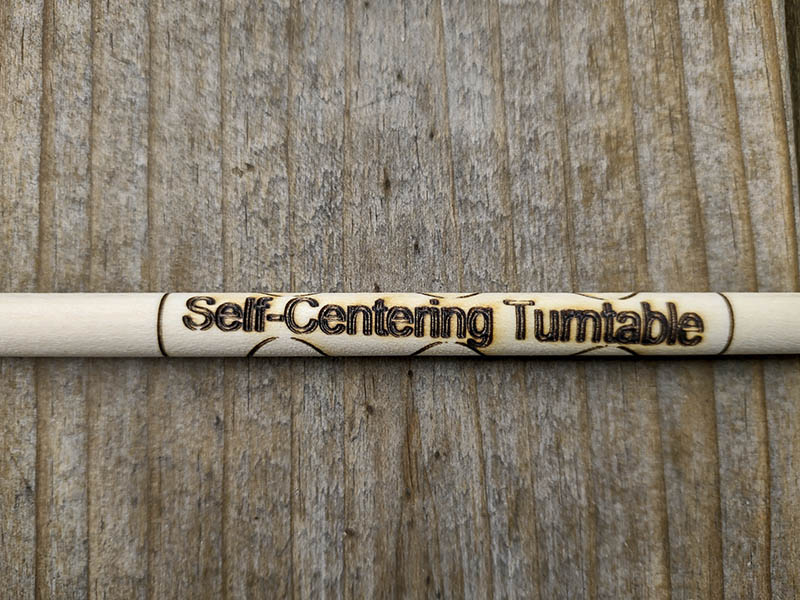

Here is a photo of test burn on a 3/8" birch dowel. It is slightly out of align with length of dowel, but I just needed to be more careful setting aligning this since it is a rather small object.

One minor comment bug with your software I noticed was it using Y instead of Z as shown in the 3rd line of this gcode output snippet, ; Bounds: X0 Y0 to X90 Y90 should be ; Bounds: X0 Z0 to X90 Z90.

; LightBurn 1.0.02

; GRBL device profile, current position

; Bounds: X0 Y0 to X90 Y90

G00 G17 G40 G21 G54

G91

M4

; Cut @ 600 mm/min, 80% power

M9

G0X18.725Z13.753

; Layer C00

G1X-0.778Z1.134S800F600

G1X-0.742Z1.189

G1X-0.705Z1.242

G1X-0.665Z1.294

G1X-0.625Z1.342

…

G1X0.044Z-1.763

M9

G1S0

M5

; return to starting pos

G0 X-89

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.