I saw an offer for a Vevor 80 watt CO2 laser but I wonder if this is a good device. Does anyone have experience with this and would like to share that experience. I now have a Sculpfun S9 with a 10 watt laser attached to it and that works fine, but it sometimes takes a long time before the work is finished. That’s why I would like to switch to a CO2. Thank you in advance for your answer and advice Bert

Unless the ad copy states, you’ll also want a “real” chiller, especially for 80W, along with an exhaust fan, typically a rather large diameter squirrel cage type blower, plus ducting, sometimes called hose.

I went from a 5W diode to a 60W CO2 and the difference is astonishing with that as a reference. Seven passes and three-quarters of an hour to cut 3 mm birch ply using the diode, to single pass, clean edges and perhaps sixty seconds!

Eighty watts is a good compromise for cutting and engraving. Too much power and you might not have good engraving results. Too little power and cutting is a chore.

If this tool has a power bed, all the better. It can be tedious to manually crank up the bed to get a good focus. If it’s auto-focus, I don’t have an opinion, but gut feeling says it should be a better machine.

The pass-through means you can cut and engrave stuff larger than the bed, another plus. LightBurn supports this sort of feature.

Hello Fred,

Thank you for your advice. As for the cooler, I will definitely look into that and I assume it will have to be the 5000 series. This seems like a very nice machine indeed. However, I don’t know if there is an automatic bed in it. I couldn’t get that from the accompanying text. I will try to ask the seller a question about this. Your advice is reassuring to me and therefore much appreciated.

Yours sincerely

Bert Klappe

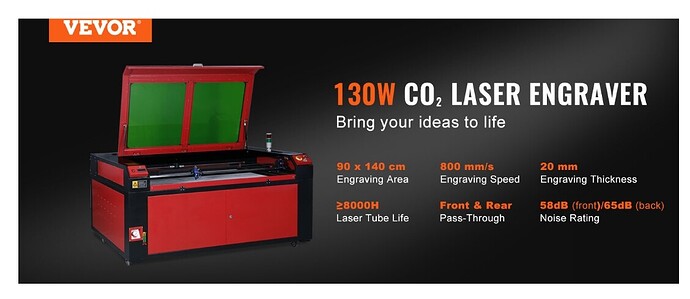

On the advertisement there is a 130 watt machine, not an 80watt machine. Forget about the advertised noise measurement, what noise is the cooler and suction but not the laser.

800 mm/s … not possible in the real life.

8000 h life of the CO2 tube … if you drive with 75% of its effect, maybe.

What I want to say take it all with a grain of salt, the machine (the one with 80watt) is more than plenty for your needs if you come from a 10watt diode.

Remember, as @fred_dot_u writes, you need to invest in the extraction and the cooler for your laser.

I myself have a Chinese 60 watt machine (OMT) and am extremely satisfied so you can be happy for this fine tool.

Hello Bernd,

Thank you for your answer and advice. I am indeed going for the 80 watts, mainly because it fits a plate of 600mm long, the lengths I always use.

I am currently working on burning images and text onto 3mm poplar plywood plates measuring 355 by 100mm and each image, together with cutting it out, takes about 15 minutes and I hope it will go much faster. The current setup is that I now engrave and cut out three plates next to each other and that takes quite a long time, especially if you have to make 500 of them. That is why I am now looking for a CO2 laser.

I also took the 800mm/s with a grain of salt, but an acceleration of the work I am now doing on the diode laser will certainly yield results. As for the extraction, I have now installed an extractor with a 100mm diameter and now I wonder whether that will also be sufficient for the CO 2 in the future.

Kind regards, Bert Klappe in the Netherlands

You will probably be happy with your new machine, 600x400 is a fine compromise and was also the largest I could get through my basement door ![]()

Ø100 for your extraction… I have a strong industrial suction on a Ø110, it should be a Ø160 if it were to be optimal, but I think you can try it out and see if you can manage with the existing one.

Greetings from Bernd/Denmark

Hello Bernd,

I will of course first try out the existing extraction, it is also satisfactory now, so we’ll have to wait and see. The 80 watt has a usable surface of 700x500mm and that is more than sufficient for my work. It just barely fits through my shed door and that was also a reason not to purchase a larger one. May I ask you what kind of coolant I should use and where I can purchase it? I prefer to do that on Sprach- und Währungseinstellungen ändern

Thank you in advance for your answer.

Yours sincerely

Bert Klappe

It is very dependent on your workshop temperature. If you never get below the freezing point, there is no need for any other than demineralized or distiled water that can be purchased in many places.

It is important, (in my opinion), not to add chemicals, for example, to avoid algae growth, it may have a negative impact on the electrical properties of your cooling system, which is a closed system and not exposed to UV light. You should change it once a year … mine is still clean and neat …

Tunder Laser recommends general coolant (https://www.thunderlaser.com/antifreeze-advice-for-co2-laser-cutter/) ![]()

OMT sells their own brand, CO2 Laser Coolant Cooler Heat Transfer Fluid – OMTech Laser). For me, it also looks like quite ordinary coolant for cars.

I will look at ethylene glycol if I had to use ice protection and use as little as possible but as much as necessary.

Hello Bernd,

Thank you so much for your advice. I will see if can get it at Amazon. It never froze in mij shet but you never know.

Bert

The OMTech coolant is virtually the same as automotive coolant. The extra additional chemistry for automotive use reduced the dielectric constant to below what you want for a coolant in a high voltage excited system like these.

The basis of most anti-freeze. It’s sweet and is responsible for many dog, cat and other animal deaths. It’s also the major component of OMTech antifreeze…

I’ve run this for a least a year, if not coming up on two.

![]()

Hello Jack,

I have found some glycol on Amazon.de and also demi water.

Thanks for your response.

Bert

I bought the 80W device with 700mmx500mm working size. I also must admit that it’s my first machine and therefore I have nothing to compare to, so take the following with a grain of salt:

While the mechnic setup is quite good, the laser tube was not completely bad, but also not really good. After 6 month I decided to replace the tube and the high voltage laser power supply, which made the device very OK to work with.

At the first tube the energy distrubution within the laser beam was rather flat, so the curf was large and the cutting depth was low. (the new tube was almost 800€)

I also added a few other features which enhanced functionality like: camera, tube current measurement, new head for confortable lens adjustment, better red dot laser mount, …

So if you are confortable to tinker, this device is a starting point, but if you need a solid device for production purpose, then I recommend to spend more money and look for something different.

PS: I have the CW-3000 water cooler (not an active chiller), which is good enough to keep the water temperature below 30°C after 3 hours of laser runtime (starting at ~23°C room temperature).

I think you want distilled water not demineralized. Distilled water has everything removed and is not conductive.

![]()

Hello Klaus, thank you for your advice. I haven’t bought the machine yet, but I’m seriously considering it. In addition to the current Sculpfun S9, I also had an Openbuilds CNC 1050 that I am busy with every day (retired), which I completely put together myself and I am not afraid to change things if necessary. I will certainly take your advice to heart.

Greetings from the Netherlands

Hello Jack, good point. Thank you.

PPS:

One thing I miss (and haven’t fixed on my machine) is the software controlled height adjustment of the bed. Although the stock device can do it electric, it can’t be controlled by software because they used an ordinary DC motor with 2 buttons for up and down. A stepper motor would be much more usefull for to changing Z height during a job…

You could start with the existing solution and see how it is going.

When is an Auto Z an advantage? If you often change the material (thickness) in the production during the day, or do you have very deep engravings/cuts where it can be an advantage of sending Z per lap … Especially if you work with foam. Otherwise … I haven’t even connected the standard electric motor and haven’t missed it either.

(you could save the money and spend it on a quiet compressor either)

you are right, but as the description sometime advert with electric hight adjustment, I thought it was worth to mention here what it means for these machines…

Hello Klaus,

It is certainly worth mentioning this and I certainly appreciate your input. Thanks

Bert From Netherlands