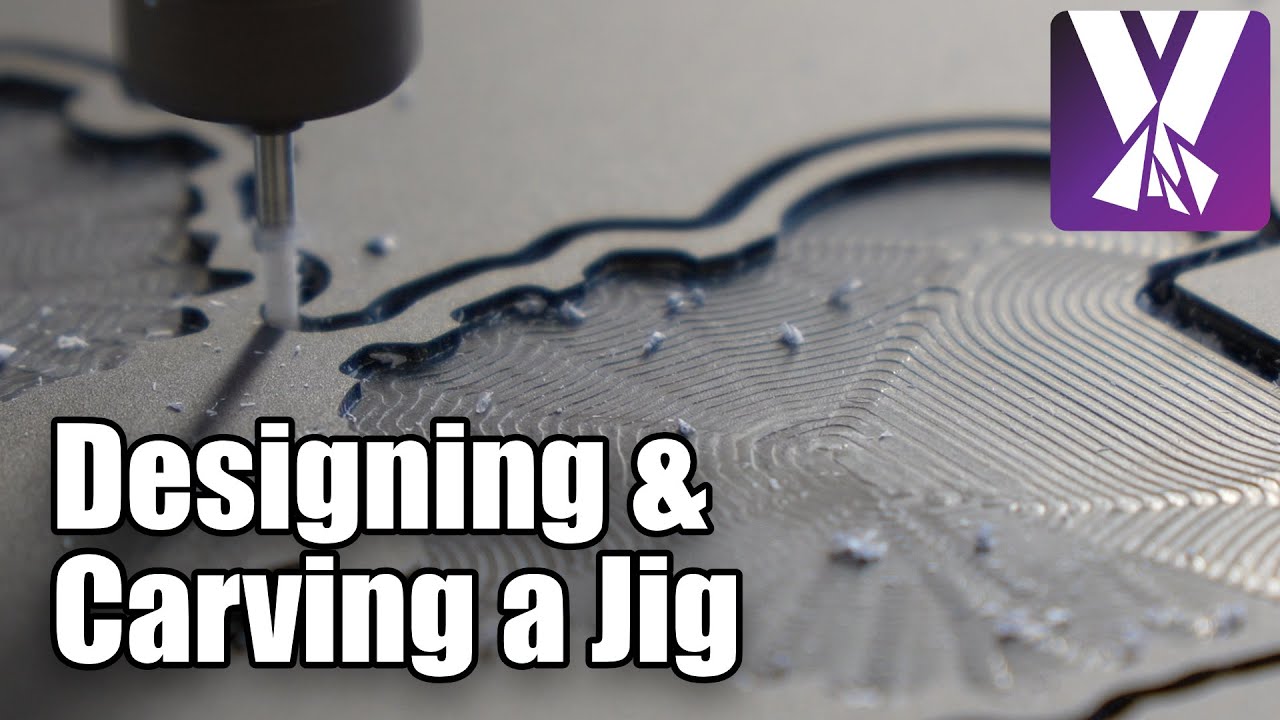

Part two of our three part series on the making of our LBX badges is all about jig creation. We used MillMage’s Circular Array and Offset tools to design and carve a precise, lightweight jig that we went on to use with a Galvo laser and LightBurn’s Repeat Marking feature.

By working with a file we could swiftly transfer between LightBurn and MillMage, we were able to make jig slots that perfectly accommodated the complex geometry of our badge design, and carve them to the exact depth necessary to account for the thickness of the badge blanks.

To catch the first video where we cut the backing blanks, head over to your LightBurn channel:

https://youtu.be/bvdXOyEOBis