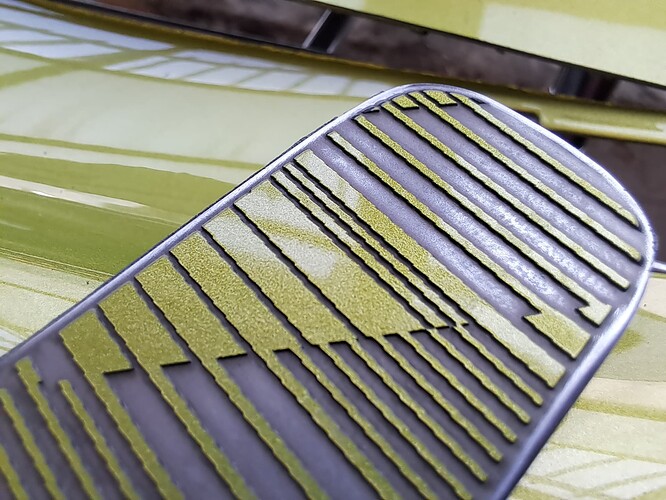

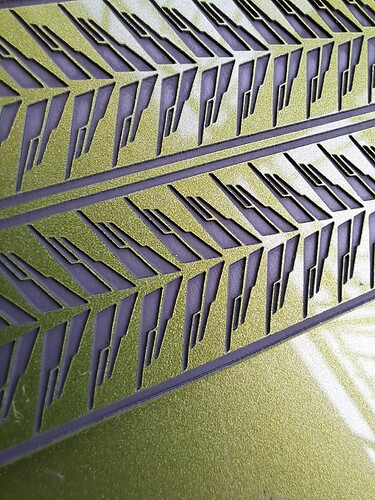

I’ve been using Lightburn for over 7 years now. Recently I’ve been doing projects that require much finer engraving precision and have come across an intermittent problem. Sometimes lines will have steps or sawtooth edges and sometimes they will be very clean. I am creating my own vector graphics so I know that there are absolutely no nodes on these edges. I can’t figure out why this only happens part of the time. I have attached one example of clean edges and one of sawtooth edges. Same material, same settings. Any thoughts?

This sound ominously familiar:

There is no resolution yet, but if you work through the same tests and also find nothing wrong, that’s a useful data point.

How big are those pieces you’re engraving? That will give us some idea of the overall scale: are the ripples 0.1 mm or 1 mm long?

Do the “good” and “bad” results differ in alignment with respect to the axes?

The distance between long lines is 3/4". The steps are parallel to the laser’s travel. I have not tried rotating the pattern to see if it changes but both of the examples shown have lines that are not parallel to the laser’s travel yet only 1 of them has the steps.

The problem shown above is different than mine. I actually had that problem a couple years ago so I replaced the rail glide and it was fixed.

That’s another one of those things that shouldn’t fail over the lifetime of the laser … maybe when a bearing fails, the laser has entered its afterlife. ![]()

The only other thing I can think of is the laser tube switching between its normal TEM00 mode and maybe TEM01 or TEM10, with the effect of making the still-focused spot larger and spreading the damage outside the usual track. I don’t know if that’s even possible, but with (all?) the mechanical problems ruled out, changes in the laser beam pattern seem the only way to produce what you and others are seeing.

If you’ve been using that laser tube for more than a few years, the tube is approaching the edge of its lifetime and maybe it’s time for a replacement.

Keep in mind that I find it remarkably easy to spend your money … ![]()

I actually already have a new laser tube ready to install as soon as this big project I’m in the middle of is out the door. I’ve been running this laser for 9 years and with a few minor repairs it’s still doing great. I’m leaning more towards the possibility of this being a software issue. I have already discovered another software issue that the Lightburn team is trying to address.

Update: rotating the design 90 degrees solved the problem. Not sure why though. I guess if I see things like this in the future I’ll just rotate.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.